P7810A-D PRESSURETROL® CONTROLLER

5

65-0268—1

3.

Mount the P7810 Controller and pressure gauge on the

end of the tee.

4.

If not convenient to mount the P7810 Controller next to

the pressure gauge, install a siphon loop in the

manufacturer provided fitting.

5.

If there is no fitting, mount the siphon loop at the boiler

manufacturer recommended location.

6.

Attach the P7810 Controller directly to the siphon loop.

7.

Level the P7810 Controller after the installation.

NOTE: The P7810C,D models require 1/2 in. (13 mm)

mounting either directly or on a siphon loop.

Remote Location Mounting

Excessive vibration at the boiler can damage the P7810

Controller electronics.

1.

Mount the P7810 Controller at a remote location to

eliminate vibration problems.

2.

Make sure that all piping from the boiler is suitable to

the application and solidly mounted.

3.

Pitch the piping properly to drain the condensate back

to the boiler.

4.

Mount the siphon loop between the remote piping and

the P7810 Controller.

5.

Level the P7810 Controller after the installation.

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect the power supply before wiring. More than

one power supply disconnect may be involved.

All wiring must comply with applicable electrical codes,

ordinances and regulations. Use NEC Class 1 line voltage

wiring.

For normal installation, use moisture-resistant No. 14 wire

(maximum size allowed) suitable for at least 167°F (75°C) or

194°F (90°C) for Flame Safeguard Primary Controls.

Use shielded wire for 4 to 20 mA modulating output and

terminate the shield to earth ground. Do not run these wires in

the same conduit as high voltage ignition wires.

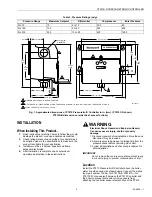

All P7810 Pressuretrol® Controllers have terminal screws and

27/32 in. (22 mm) holes in both sides for conduit, cables and

wiring. Remove the top cover by loosening the screw at the

top of the P7810 Controller case.

Follow the burner or boiler manufacturer wiring diagram, if

provided. Make sure the loads do not exceed the contact

ratings in the Specifications section. See Fig. 5 for terminal

locations and Fig. 6 through 10 for typical wiring hookups.

Replace the front cover after completing the wiring.

Fig. 5. P7810C,D Pressuretrol® Controller.

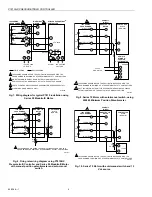

Fig. 6. Firing rate wiring diagram using 4 to 20 mA

controller and Series 70 Modutrol® Motor.

1/4 IN. NPT

1/4 IN. NPT

1/2 IN. NPT

STEAM

PRESSURE

CONTROL

SENSOR

STEAM

PRESSURE

HIGH LIMIT

CONTROL

SENSOR

NPT

M11895D

1 USE COPPER CONDUCTORS ONLY

1

1

+mA

-mA

OUTPUT

L2

GND

ALARM

LINE VOLTAGE

L1

(MODULATE)

PROGRAMMER WIRING

HIGH FIRE

COMMON

MODULATE

LOW FIRE

F

-

–

+

MODUTROL®

MOTOR

P7810

CONTROLLER

M17130A

+