C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

3

60-2398-17

C7012G: Mounting flange with 3/4 inch NPT internal threads

for attaching to sight pipe.

C7012C and F: Pipe union with 1 inch NPT internal threads for

attaching to sight pipe.

Wiring Connections:

NEC Class 1 Color-Coded Leadwires:

Length: 8 feet (2.4 meters).

Number of Leadwires:

C7012A and C: 4.

C7012E and F: 6.

C7012G: 5.

C7012E1278 contains Brad Harrison™ Type 41310

Connector. Mating connector (Brad Harrison™ Type

41306N or 41307N not provided by Honeywell).

NOTE: Models designed to meet DIN (German) and

BGC (British) requirements have an additional yellow/

green leadwire that is used as a separate ground

wire.

Threaded Leadwire Opening in Faceplate:

C7012A and E: 1/2-14 NPSM internal threads for

attaching conduit.

C7012C and F: 1/2-14 NPT internal threads for

attaching pipe.

Dimensions:

See Fig. 1 or 2.

Weight:

C7012A,E and G: Approximately 4.25 pounds (1.9 kg).

C7012C and F: Approximately 14.5 pounds (6.6 kg).

Serviceability:

All Models: Field-replaceable viewing window and ultraviolet

sensing tube.

C7012E and F: Field-replaceable self-checking coil and shutter

assembly.

NOTE: The 190971B Coil and Shutter Assembly can

be used on existing C7012 Detectors with electron

tubes, but the old 120625B Coil and Shutter

Assembly cannot be used on solid state C7012 Flame

Detectors.

Interchangeability:

Solid State C7012A,C,E,F and G Purple Peeper® Ultraviolet

Flame Detectors are interchangeable with similar models of

earlier C7012 Flame Detectors.

SIL 3 Capable:

The C7012E or F when used with a R7847C self-check

amplifier in Relay Module EC7810A, 20A, 30A, 40L, 50A;

RM7800[E,G,L,M], 30A, 38[A,B,C], 40[E,G,L,M] 50A,

90[A,B,C,D], 97[A,C], 98A is SIL 3 Capable in a properly

designed Safety Instrumented System. See form number 65-

0312 for Certificate Agreement.

Approvals:

Underwriters Laboratories Inc. Listed (120 Volt

Models Only):

C7012A and E (except C7012E1161 and E1278):

File no. MP268.

C7012C and F: For use in hazardous locations;

Class I, Groups C and D; Class II,

Groups E, F and G; File no. E34649.

Canadian Standards Association Certified (120 Volt Models

Only): C7012A and E: Master File LR95329-1.

Factory Mutual Approved: A,C,E and F models, 14740.01.

SwissRe (formerly Industrial Risk Insurers) Acceptable.

DIN: 220 volt models of European C7012E and G are designed

to meet DIN requirements.

British Gas Corporation: 110 and 240 volt models of European

C7012E and G are designed to meet British Gas

Corporation requirements.

Replacement Parts:

All Models:

113228 Ultraviolet Sensing Tube.

191286 Ultraviolet Sensing Tube for -40°F

(-40°C) operation.

114465 Gasket, silicone rubber; for installing viewing

window (three required).

C7012A,E and G:

114372 Quartz Viewing Window; rated for 20 psi (138 kPa).

32004080-001 Electronic Assembly (C7012A)

191702 Electronic Assembly with Shutter (C7012E)

120739 Gasket, fiber-neoprene; heat insulation and

seal-off for mounting flange.

C7012C and F:

122037 Quartz Viewing Window; rated for 100 psi (690

kPa).

32004080-001 Electronic Assembly (C7012C).

191702 Electronic Assembly with Shutter (C7012F).

C7012E and F:

190971B Coil and Shutter Assembly for all models except

220V/50 Hz.

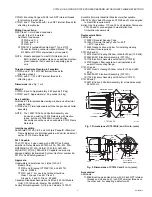

Fig. 1. Dimensions of C7012A,E, and G in in. (mm).

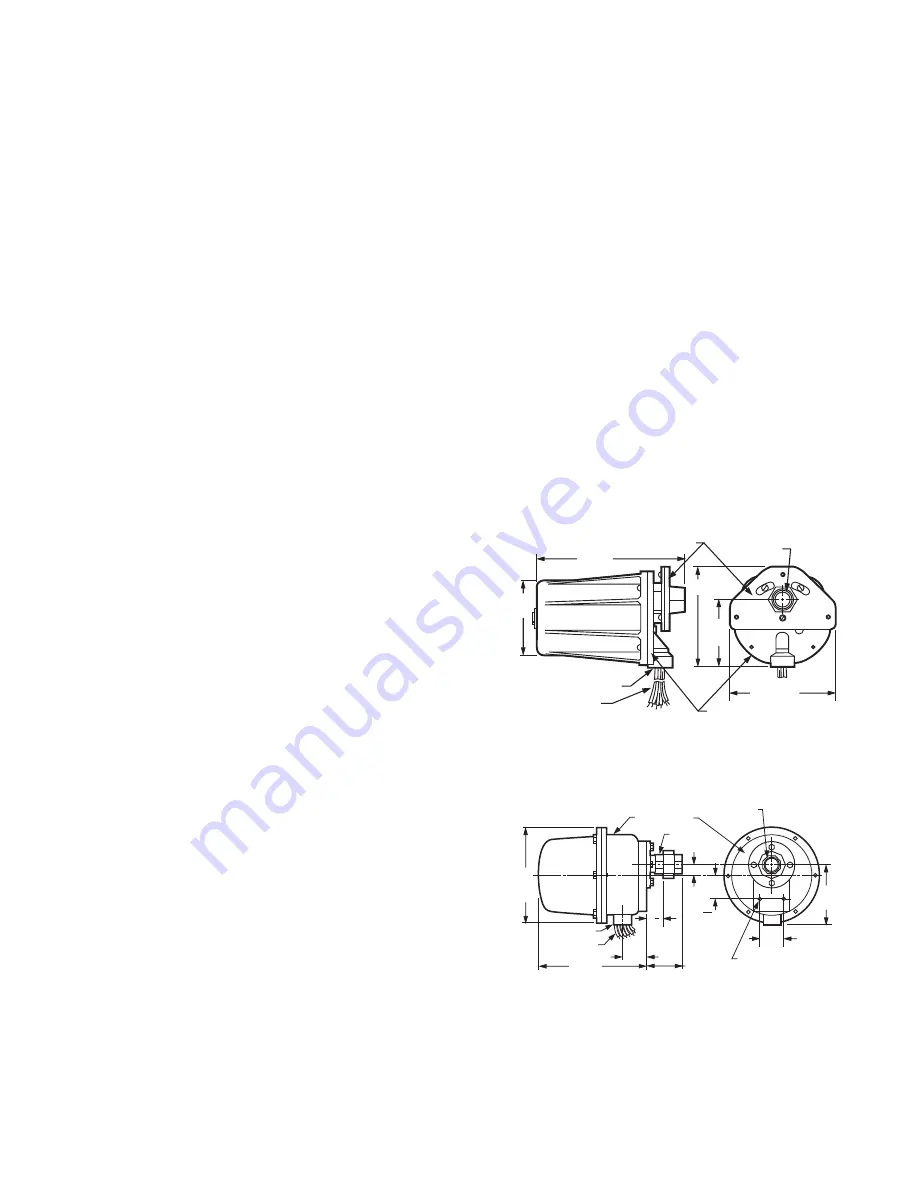

Fig. 2. Dimensions of C7012C and F in in. (mm).

Accessories:

All Models:

118369 Bushing, galvanized iron, with 3/4 inch NPT internal

threads on one end and 1 inch NPT external threads on

the other end. For adapting a detector with

MOUNTING FLANGE

1/2-14 NPSM

LEADWIRES

FACEPLATE

3/4Ð14 NPT

M1962B

3-3/4

(95)

7-7/32

(183)

5-1/8 (130)

3-7/16

(87)

5-1/4 (133)

C7012A,C,E,F

1/2–14 NPT

5

(127)

2

(51)

1(25)

8

(203)

DIA.

9 (229)

2(51)

2

(52)

1

16

1

(38)

1

2

3 (76)

LEADWIRES

FACEPLATE

PIPE

UNION

1–11 1/2 NPT

5/16–18 UNC–2B BY

7/16 (11) DEEP

MOUNTING HOLES (2)

M1963