C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

60-2398-17

6

Screening Effects

Smoke, oil mist, dirt and dust are masking agents that

attenuate the ultraviolet radiation that the flame emits. If they

absorb too much radiation, the amount of ultraviolet radiation

reaching the detector is reduced. The flame signal then can

become too low to hold in the flame relay, resulting in burner

shutdown.

Diluting the contaminants can eliminate the problem. A strong

flow of air through the sight pipe clears a viewing path through

the attenuating material. Refer to the Sight Pipe Ventilation

section.

It is also desirable to sight the detector in an area containing

fewer masking agents such as near the burner nozzle or near

the entrance of the combustion air. Increasing the viewing area

of the detector by shortening the sight pipe or by increasing the

diameter of the sight pipe also reduces the attenuating effects

of masking agents.

Multiburner Requirements

(Flame Discrimination)

In addition to meeting the requirements for a single burner, a

multiburner installation requires discrimination between flames.

Flame discrimination can be defined as locating all flame

detectors so that each detector responds only to the flame of

the burner it is supervising.

In multiple burner systems, not every detector can be

positioned so its line-of-sight does not intercept flames from

other burners. For example, this situation occurs in front-fired

boiler-furnaces having more than one row of burners, or in

multilevel opposed-fired furnaces where the burners face each

other.

When planning such an installation, locate each flame detector

so that it has the best possible view of the first

30 percent closest to the burner nozzle (the flame root) it is

supervising, and the worst possible view of all other flames.

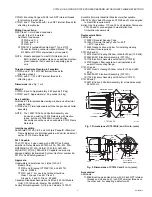

Fig. 4 illustrates a critical detector application problem that

requires flame discrimination. Flame discrimination is

accomplished for Detector A by repositioning it until the flame

relay (in the flame safeguard control) does not respond to

Flame B. Note that Detector A is aimed at the first 30 percent

of Flame A where the ultraviolet radiation is most intense.

It sights the tip of Flame B, but it is not aimed at the first

30 percent of Flame B where UV is intense. Detector A is

repositioned to assure maximum response to Flame A while

rejecting Flame B. Similarly, Detector B is positioned to assure

maximum response to Flame B while rejecting Flame A.

If you reposition a detector and still cannot achieve flame

discrimination, try reducing the viewing area by increasing the

length or decreasing the diameter of the sight pipe, or adding

an orifice plate.

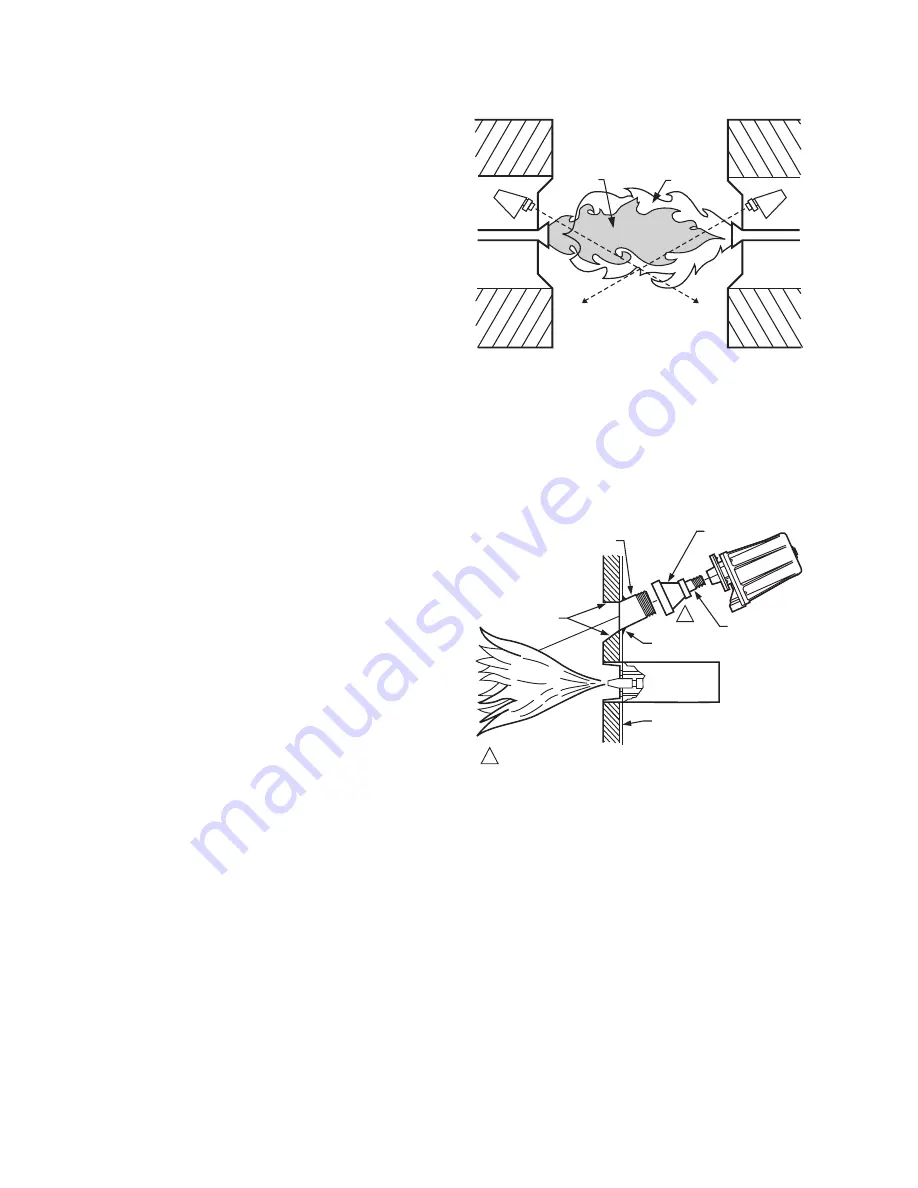

Install the Sight Pipe (Fig. 5)

After you have determined the location and sighting angle,

select the sight pipe. A black iron pipe with a diameter of at

least 1-1/2 in. (38 mm) is recommended. Do not use stainless

steel or galvanized pipe because they reflect ultraviolet

radiation internally and complicate aiming the pipe.

Fig. 4. Example of flame discrimination

problem (opposed-fired burners).

Sight pipes with diameters 2 to 3 in. (51 to 76 mm) produce

better results for horizontal rotary burners, which require wide

viewing angles. A wide viewing angle can also be obtained by

using a short sight pipe.

Fig. 5. Typical mounting of C7012.

Prepare Hole in Combustion

Chamber Wall

Cut or drill a hole of the proper diameter for the sight pipe in the

wall of the combustion chamber at the selected location. Flare

the hole to leave room for small adjustments of the sighting

angle. The taper of the hole should be about 1 in. for every 3

in. (25 mm for every 76 mm) of wall thickness.

Mount Sight Pipe

Thread one end of the pipe to fit the mounting flange, union, or

required coupling. Cut the pipe to the desired length (as short

as practical) and at an angle so it fits flush with the wall of the

combustion chamber. Tack weld the pipe to the wall in a trial

position. Do not weld the sight pipe permanently in place until

after completing the Adjustments and Checkout procedures.

M1957

DETECTOR A

FLAME A

DETECTOR B

FLAME B

1

CLOSE NIPPLE

(3/4 in. FOR

A C7012E; 1 in.

FOR A C7012F.

TEMPORARY

TACK WELD

COMBUSTION

CHAMBER WALL

REDUCER

BLACK IRON SIGHT

PIPE (1-1/2 TO 3 in.

[38 TO 76 mm] DIA.)

REFRACTORY

FLARED

HOLE

1

IF VENTILATION OF THE SIGHT PIPE IS REQUIRED, ADD PIPE

TEE, PERFORATED NIPPLE, OR OTHER SUITABLE DEVICE

FOR VENTILATION.

M6814