C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

60-2398-17

12

ADJUSTMENTS AND

CHECKOUT

UV Sensor Tube Test

For initial burner lightoff, consult the burner manufacturer

instructions or the instructions for the flame safeguard control.

If the system does not start during the initial burner lightoff,

check the UV sensor tube in the flame detector. If a reddish

glow appears when there is no flame present, replace the UV

sensing tube. When performing this test, make sure there are

no extraneous sources of ultraviolet radiation in the test area

(see Radiation Sources section).

Adjust Detector Sighting

With the flame detector installed and the burner running, adjust

the sighting position of the detector for optimum flame signal.

Most existing Honeywell flame safeguard controls incorporate

a flame current jack on the control flame amplifier or on the

control itself. Measure the flame signal with a volt-ohmmeter

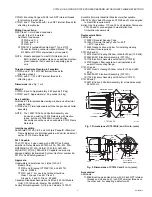

such as the Honeywell W136A Volt-ohmmeter (see Fig. 17). To

measure the flame current (signal), use 196146 Cable

Connector, included with W136A, in conjunction with the meter.

With the W136A (or equivalent) positioned to the zero to 25

microampere scale, connect the meter probes to the two ends

of the cable connector plug (red to red, black to black). Insert

the plug end of the connector plug directly into the flame jack of

the control or control amplifier (see Fig. 17). The W136A Meter

then directly reads the flame signal in microamperes. Refer to

Table 1 for minimum acceptable flame currents.

Fig. 18. Measuring microamp flame signal.

The R7747C and R7847C Amplifiers used with the BCS 7700

and 7800 Series Flame Safeguard controls, respectively, have

a dc voltage flame signal output. For the R7747C Amplifiers, a

volt-ohmmeter with a 20,000 ohm/volt minimum input

impedance and a zero to five or ten Vdc scale is

recommended. It is suggested that a volt-ohm meter with a

minimum sensitivity of one megohm/volt and a zero to five or

ten Vdc scale be used for R7847C Amplifier flame signal

measurements. Measure the flame signal as illustrated in

Fig. 18 and 19. Be careful to make the proper connections of

positive (red) meter lead to positive (+) control jack and

negative (black) meter lead to negative (-) or (-Com) jack with

7800 Series controls. If the BCS 7700 and 7800 Series

controls have the Keyboard Display Module, a zero to five Vdc

voltage displays on the module.

Fig. 19. Measuring voltage flame

signal with BCS 7700 (currently obsolete) controls.

Fig. 20. Measuring voltage flame

signal with 7800 Series controls.

W136A VOLT-

OHMMETER

W136A SELECTOR

SWITCH

196146 METER

CONNECTOR

PLUG

PLUG

PLUG-IN FLAME

SIGNAL AMPLIFIER

FLAME SIGNAL

METER JACK

RED CONNECTOR

BLACK CONNECTOR

BLACK (–) METER LEAD

RED (+)

METER

LEAD

M6532A

RESET

BUTTON

PROGRAM

MODULE

20,000

VOLT-

OHMMETER

BCS 7700 CHASSIS MODULE FOOTMOUNT

METER

PROBES

FLAME

AMPLIFER

M7860

NEGATIVE (-)

METER LEAD

POSITIVE (+)

METER LEAD

ONE MEGOHM

MINIMUM INPUT

IMPEDANCE

METER

M6818