C7012A,C,E,F,G SOLID STATE PURPLE PEEPER® ULTRAVIOLET FLAME DETECTORS

60-2398-17

4

1 inch NPT internal threads (for mounting) to a 3/4 inch

sight pipe, or to the pipe nipple and tee for connecting an

air supply.

W136A Test Meter (includes 196146 Meter

Connector Plug).

117053 Meter Connector Plug (for older W136A models).

C7012A,E and G:

122748 Quartz Viewing Window, rated for 50 psi

(345 kPa).

124204 Quartz Focusing Lens, rated for 20 psi (137 kPa);

for increasing the detector-sensed ultraviolet radiation.

Flange, aluminum, with 1 inch NPT internal threads for

attaching to sight pipe.

123539 Antivibration Mount.

190105 Water Jacket.

Swivel Mount.

Seal-off Assembly, for seal-off of 3/4 in.

NPT pipe.

204341A UV mirror with 3/4 in. NPT internal threads.

INSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced flame safeguard

service technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Equipment Damage Hazard.

Sensing tube can fail to discriminate between

flame conditions.

Change sensing tube after 40,000 hours of

continuous use.

Appliances with burners that remain on continuously for

24 hours or longer should use the C7012E,F Flame Detector

and the R7247C, or R7847C Amplifiers and associated

controls.

WARNING

Electrical shock hazard.

Can cause serious injury or death.

Disconnect power supply before beginning installation

to prevent electrical shock and equipment damage.

More that one disconnect can be involved.

IMPORTANT

1. Do not connect these detectors to non-Honeywell

manufactured controls (primaries, programmers,

multiburner systems, and burner management

systems). Unsafe conditions could result.

2. All wiring must be NEC Class 1 (line voltage).

3. Voltage and frequency of the power supply connected

to this detector must agree with the values marked on

the detector.

4. The detector must be sighted so it does not respond

to ignition spark.

5. On multiburner installations, each detector must

respond only to the flame produced by the burner it is

supervising.

6. Do not connect more than two C7012 Flame

Detectors in parallel.

Proper flame detector installation is the basis of a safe and

reliable flame safeguard installation. Refer also to the burner

manufacturer instructions. Carefully follow the instructions for

the best possible flame detection application.

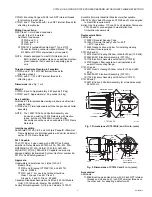

Basic Requirements

The combustion flames of most carbon-based fuels emit

sufficient ultraviolet radiation to enable the C7012 Solid State

Purple Peeper® Ultraviolet Flame Detector to prove the

presence of a flame in a combustion chamber. The detector is

mounted outside the combustion chamber. Its mounting flange

or union is threaded to one end of a sight pipe inserted through

the wall of the combustion chamber. The ultraviolet sensing

tube in the flame detector sights the flame through the pipe.

When a flame is present, the UV tube in the C7012 senses the

ultraviolet radiation emitted. The C7012 produces a signal that

is sent to the amplifier in the flame safeguard control. The

amplified signal pulls the flame relay into the control to allow

proper operation of the system.

Because it is necessary for the UV sensing tube to actually see

the flame, it is best to locate the detector as close to the flame

as physical arrangement, temperature, and other restrictions

permit. These restrictions are described in detail in the

following paragraphs.

Determine Location

Before beginning the actual installation, determine the best

location for mounting the detector. Carefully consider the

factors discussed in this section before deciding on

the location.

Temperature

Install the C7012 where the ambient temperature (outside the

case) stays within the ambient operating temperature ratings.

To keep the C7012 below its maximum rating, it may be

necessary to add additional insulation between the wall of the

combustion chamber and the detector. A shield or screen can

be added to reflect radiated heat away from the detector. If the

detector continues to get too hot, cooling is necessary. Refer to

the Sight Pipe Ventilation section. A 190105 Water Jacket is

also available for cooling the C7012A,E,G Flame Detectors.

See Accessories.

Vibration

If the C7012 is subject to excessive vibration, use a special

123539 Antivibration Mount for the C7012A,E or G. If you use

this mount, install it before you position and sight the detector.