R7195A,B MOTOR POSITIONER

3

63-2582

Fig. 1. R7195A,B Motor Positioner approximate dimensions in in. (mm).

INSTALLATION

When Installing this Product…

1.

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

The installer must be a trained, experienced technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before beginning installation.

More than one disconnect may be needed.

Equipment Required

To install the R7195A,B Motor Positioner, you will need:

1.

Electric drill.

2.

Drill bits (No. 23, No. 37).

3.

Four No. 6 machine screws or four No. 6 self-tapping

screws.

4.

Standard screwdriver.

5.

Small adjustable wrench.

6.

Center punch and hammer.

Procedure

Refer to Fig. 1 and layout of the centers of the mounting hole

locations on the mounting surface.

1.

Use a center punch and hammer to mark the locations

for drilling.

2.

Depending on the characteristics of the mounting

surface, drill clearance holes (No. 23 bit) for No. 6

machine screws or starting holes (No. 37 bit) for No. 6

self-tapping screws.

3.

Place the positioner on the surface so that the mounting

holes are aligned with those drilled in the surface and

secure with the machine screws and nuts or self-tapping

screws, as applicable.

4.

Install separate conduit for controller leads and

operating voltage leads.

WIRING

General

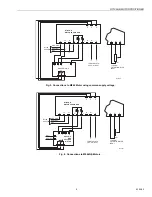

All wiring must comply with all applicable local electrical

codes, regulations and ordinances. When wiring more than

one motor positioner to a controller, make sure that the total

impedance of positioners and wiring is less than the output

impedance of the controller.For example, the R7355

DialTrol™ Controller can be wired to a maximum of eight

R7195A Motor Positioners. The R7355 Controller is capable

of driving a load of up to 650 ohms. See Fig. 2.

3-3/4 (95)

6-9/16

(167)

3/4 (14) NPSM (2)

7-3/8

(187)

3-1/2 (89)

3/16 (5)

M20786

4-29/32 (124)

7-25/32

(198)

Summary of Contents for R7195A

Page 11: ...11 63 2582 ...