R7195A,B MOTOR POSITIONER

7

63-2582

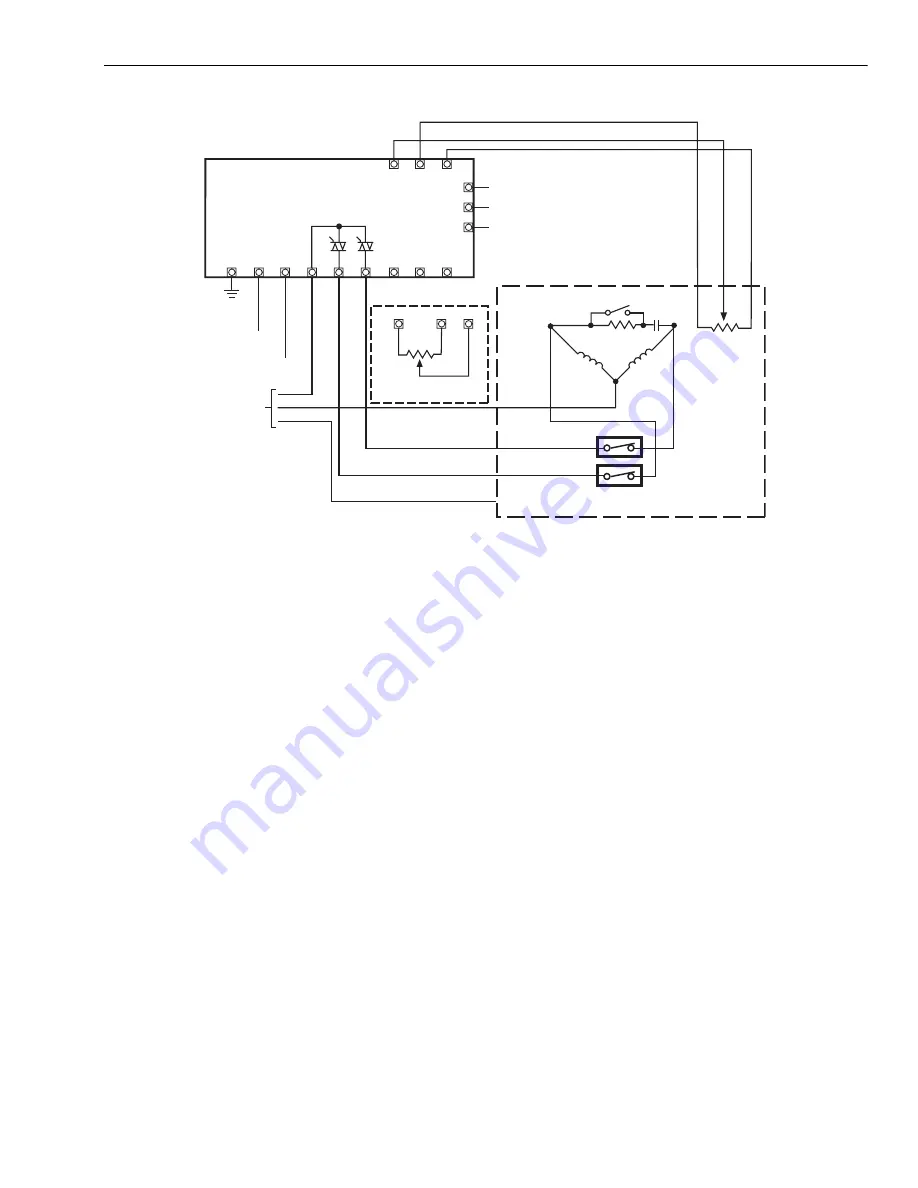

Fig. 9. External wiring diagram.

Heating Application # 1:

When the temperature at the sensor is above the range of the

controller, the controller output will be above the proportioning

range of the controller. For example: the controller output

signal will be less than 4 mA for a 4-20 mA range controller;

motor positioner triac Q3 will fire to drive the motor to the

closed position.

Heating Application # 2:

When the temperature at the sensor is below the range of the

controller, the controller output will be below the proportioning

range of the controller. For example: the controller output will

be greater than 20 mA for a 4-20 mA range controller. Motor

positioner triac Q4 will fire to drive the motor to the open

position.

Heating Application # 3:

When the temperature at the sensor is within the

proportioning range of the controller; Q3 triac will fire as the

sensor temperature rises above the controller setpoint to drive

the motor in the closed direction. Q4 triac will fire as the

temperature at the sensor drops below the controller setpointt

to drive the motor in the open direction.

In each case the motor will move until a new balance point is

reached such that the error voltage between the input signal

and the slidewire signal is zero.

SERVICE AND TROUBLESHOOTING

Calibration Procedure

NOTE: The R7195 Motor Positioner is calibrated at the

factory for a 4-20 mA input signal for the R7195A

and a 135-ohm potentiometer input for the R7195B.

Therefore, do not calibrate the motor positioner

unless the input signal desired is something other

than 4-20 mA (R7195A) or 135 ohms (R7195B).

To calibrate the positioner, refer to Fig. 9.

For the span and zero adjustment check, do the following:

1.

Connect the input source (4-20 mA or 135-ohm

potentiometer) to terminals R, B and W.

2.

Set the input to the minimum value of span. Adjust the

zero potentiometer (P3) to balance out the motor and

the minimum limit.

3.

Set the input to the maximum value of span. Adjust the

span potentiometer (P1) to balance out the motor at the

maximum limit.

Deadband Adjustment

The deadband adjustment (P2) will be set at the mid position

to provide precise control of the process for most process

applications. Some processes may require deadband

adjustment to achieve stable control. Unstable process

conditions may be characterized by:

(P1) SPAN ADJUST

(P2) DEADBAND ADJUST

(P3) ZERO ADJUST

M202794

GROUND

NEUTRAL

HOT

GROUND

R7195 SUPPLY

HOT

ROTOR SWITCH

CCW

CLOSE

CW

OPEN

MOTOR

WINDINGS

Q4

Q3

LIMIT

SWITCHES

NEUTRAL

G

GROUND

MOTOR

SUPPLY

COMMON

4-20 mA INPUT

MOTOR

B

W

R

CW

135-OHM

POTENTIOMETER INPUT

R7195A,B

MOTOR POSITIONER

5

4

6

G

L2

L1

2

3

1

B

W

R

Summary of Contents for R7195A

Page 11: ...11 63 2582 ...