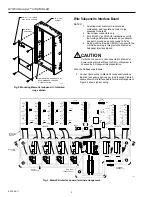

MacroCel

INTERFACE

BOARD

MOUNTING

TAB (2)

R7515C MacroCel™ CONTROLLER

95-7456—1

3

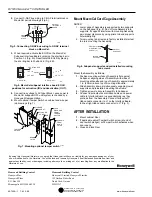

C5611

1

2

3

4

5

6

7

8

9

10

11

12

13

14

R1

RTD

D1

DIG

+10

+10

V1

VOLT

R2

RTD

D2

DIG

V2

VOLT

TB1

R1

R2

TERM V1

TERM V2

15

16

17

18

19

20

21

22

23

24

25

26

27

28

R3

RTD

D3

DIG

+10

+10

V3

VOLT

R4

RTD

D4

DIG

V4

VOLT

TB2

R3

R4

TERM V3

TERM V4

29

30

31

32

33

34

35

36

37

38

39

40

41

42

R5

RTD

D5

DIG

+10

+10

V5

VOLT

R6

RTD

D6

DIG

V6

VOLT

TB3

R5

R6

TERM V5

TERM V6

R7

RTD

D7

DIG

+10

+10

V7

VOLT

R8

RTD

D8

DIG

V8

VOLT

TB4

47

48

49

50

51

52

53

54

55

56

43

45

46

44

J1

J2

J3

J4

R7

R8

TERM V7

TERM V8

5 7

5 8

5 9

6 0

+

+

24 VDC

TB10

C1

TO-1

TB5

65

66

67

68

69

70

71

72

61

63

64

62

COM1-2

TO-2

TO-3

COM3-4

TO-4

T1

T2

T1

T2

T1

T2

O

U

T

P

U

T

T

R

I

A

C

2

4

V

A

C

POWER

LED

F1

2A

+

CR2

TB8

POWER

24VAC T1

24VAC T2

J5

CNAP

BUS

JACK

ON

OFF

S1

A

EOL

J6

J7

1

2

3

1&2

2&3

J8

3

7 4

5

+

+

CNAP

OUT

IN

7 6

TB9

IN

OUT

AO—1

TB6

77

78

RET

ANALOG

79

80

AO—2

RET

AO—3

TB7

89

90

RET

ANALOG

91

92

AO—4

RET

MacroCel

CARD CAGE

JB1

INPUTS

WALL MOD

CONNECTOR J8

0. 16A MAX

CNAP

BUS

0.16A MAX

83

84

85

86

87

88

A

C

B

A

C

B

K1

K2

OUTPUTS

95

96

97

98

99

100

A

C

B

A

C

B

K3

K4

7

7

SUBPANEL

SUPPORT (2)

81

82

AO—5

RET

93

94

AO—4

RET

Fig.

4.

Macr

oCel typical wiring.