RETROFIT ROUND DAMPER (RRD)

3

69-1960

INSTALLATION

Before Installing this Product

1.

Read all instructions before installing this product. Fail-

ure to follow instructions can damage the product or

cause a hazardous condition.

2.

Check the ratings given in the instructions and on the

product to verify that the product is suitable for your

application.

3.

Installer must be a trained and experienced service tech-

nician.

4.

Install the product in an area that is easily accessible for

checkout and service.

5.

After completing installation, use these instructions to

check out product operation.

Installing the Retrofit Round Damper

Select a location for the damper in the ductwork. It is

suggested that the RRD damper be at least 6 feet from the

register for quiet operation.

1.

Peel off the back of the cut-out template. Carefully align

the template with the centerline of the duct. Apply tem-

plate to the section of round ductwork where the damper

is to be installed. Ensure that the template is parallel to

the ductwork. It is suggested that the damper be installed

with the motor under a horizontal duct to reduce twist to

the duct. It may also be necessary to support the duct.

2.

Drill a starter hole in the cut-out area of the template.

3.

Cut out the area between the holes.

4.

Slide the damper into the duct and secure it with the four

supplied self-drilling mounting screws. Be careful to

avoid over-tightening the screws as the duct may be

pulled out of round. See Fig. 3.

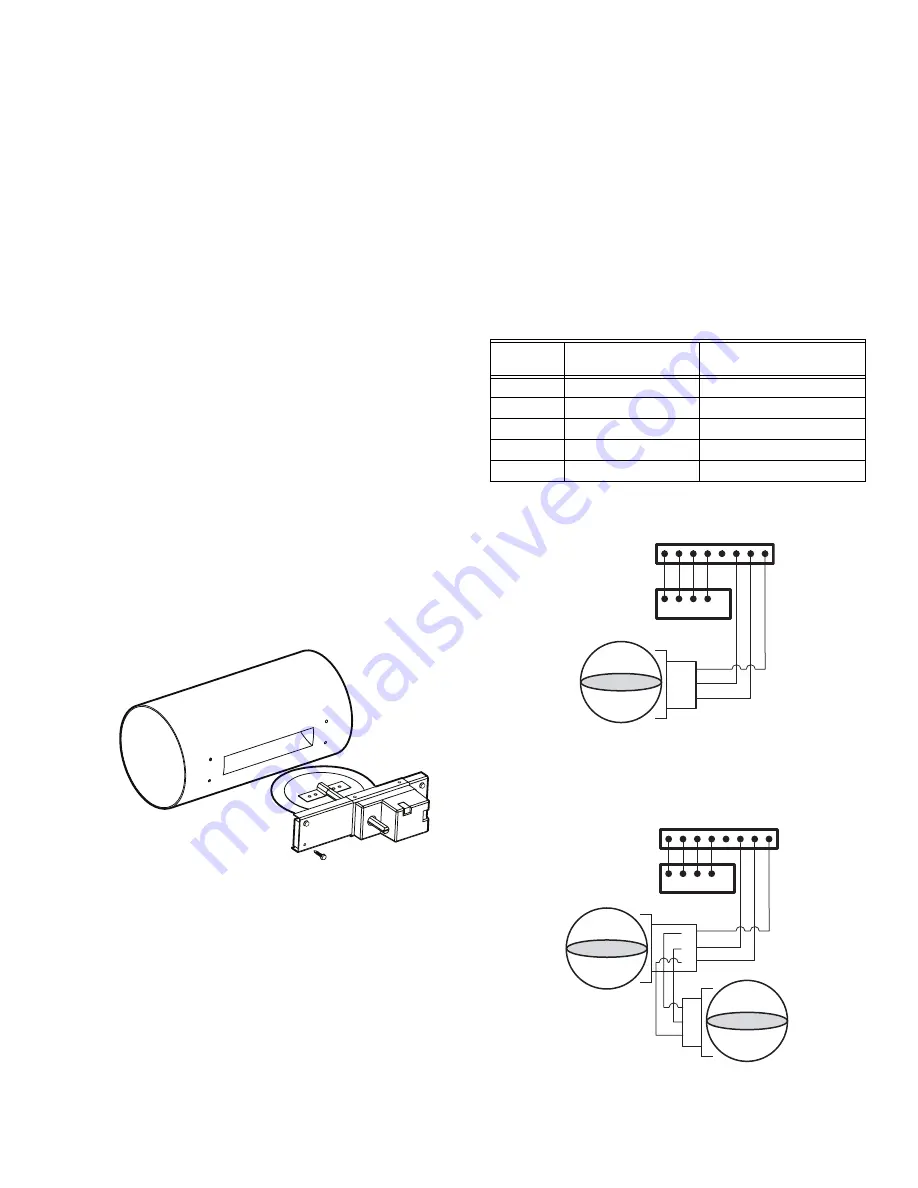

Fig. 3. Inserting RRD damper into duct.

WIRING

Wiring the Motor Actuator

Connect the motor to the zone control panel 18 or 20 gauge

wire. The motor terminals are labeled M1 for common, M6 for

closed, and M4 for open. Connect the motor terminals to

corresponding terminals on zone control panel for each zone.

See Fig. 4–6 for hookups.

Multiple RRD dampers can be wired to one zone when wired in

parallel. See Fig. 5 for wiring multiple dampers together in a

daisy chain manner or Fig. 6 using wire nuts. See Table 1 for

the maximum number of dampers that can be connected to

each zone control panel. Note that this is the total number of

dampers connected to all the zones of a zone control panel;

the maximum dampers per zone is 14. If more than 14

dampers are on one zone, a Slave Damper Control Relay

(SDCR) must be used.

When more than the maximum number of dampers allowed

per panel are necessary, a SDCR must be used. The SDCR is

an isolation relay that is powered by a separate transformer so

that it relieves the panel of this additional load. When a SDCR

is used, the dampers of that zone may either be all connected

to the SDCR, or some dampers may be wired to the SDCR and

the remainder to that zone’s damper terminals.

Fig. 4. RRD wired to zone control panel.

Fig. 5. Wiring multiple RRD dampers in daisy chain

fashion.

M23404

Table 1. Maximum number of dampers per zone.

One 40 VA

Transformer

Two 40 VA Transformers

(or One 75 VA)

Emm-3

12

N/A

Emm-3u

12

N/A

Tz-4

11

25 (max 14 per zone)

W8835

12

26 (max 14 per zone)

SDCR

15

28

R Y W G C M6 M4 M1

R Y W G

ZONE

1, 2, 3, ETC.

M1

M6

M4

M23405

ZONE

THERMOSTAT

R Y W G C M6 M4 M1

R Y W G

ZONE

1, 2, 3, ETC.

M1

M6

M4

M1

M6

M4

M23407

ZONE

THERMOSTAT