61

EN2R-9031 0402R15-NE

ELECTRICAL CONNECTIONS AND WIRING

IMPORTANT

Take care that installer is a trained experienced

service person.

Disconnect power supply to prevent electrical shock

and/or equipment damage.

Turn off gas supply before starting installation.

Wiring must be in accordance with local regulations.

The appliance manufacturer’s instructions should

always be followed.

Before installing or replacing any control check that

type number is correct for the application.

Ensure combustion chamber is free of gas before

start up.

Conduct a thorough check out when installation is

completed.

At the first start the ignition controller can be in lock

out; depress reset button to free control.

CAUTION

Do not connect the ignition control to power supply

when it is not connected to the gas control.

Wiring

•

Use cable which can withstand 105°C ambient.

•

Use cable which is proven against moisture.

•

Wiring between ignition control and spark sensing probe

should have good quality insulation, suitable for the

temperatures encountered.

CAUTION

CAUTION

If ignition frequency q 25 Hz or pulse energy

> 45

µ

As the ignition cable and its connections shall

have a protection against electrical shock hazard.

For single rod applications, the ignition/sensing cable

and its connections shall have protection against

electrical shock hazard.

Label all wires prior to disconnection when servicing

ignition controls. Wiring errors can cause improper

and dangerous operation.

If electronics components are installed in an area

subject to water (dripping, spraying, rain etc.), means

shall be provided to protect these components.

Flame relay output is not accessible when the

normally closed output is present.

Fusing

In order to prevent unsafe conditions at too high current, the

ignition controls have an integral non replaceable fuse.

This fuse will be blown long before the maximum 16 A

external fuse switches off.

Spark gap

Max. allowable spark gap 3.5 mm

Supply voltage polarity

WARNING

If ignition control

(without the phase neutral

independent operation feature)

seems to operate

normally but does not detect flame, check for right

polarity of power supply (line, neutral).

Checking flame current

•

The minimum value should be in accordance with

specified value.

•

To check flame current connect a dc micro-Ampèremeter

between flame sensing wire and flame sensing rod.

•

Meter connections polluted with e.g. alkaline substances

lying close to earth can cause flame current simulation.

Make sure no false flame current can flow from meter

connections to earth.

•

If flame current is insufficient check that the flame sensing

rod is fully enveloped by the flame and that burner and

ignition control are reliable grounded.

•

If there is no sufficient flame current due to phase-phase

mains it is recommended to use an ignition control with the

phase neutral independent operation feature. If this is not

available, it is recommended to use a AT7030A or

AT7030B flame detection transformer. See also instruction

sheet EN1R-9136 for the AT7030 transformer.

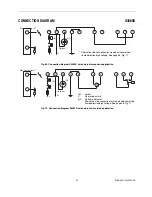

Flame sensing wiring

The S4565/S4575 and S4585 ignition controls are equiped

with flame sensing by ionisation current based on the flame

rectification principle.

Via a high ohmic source a high voltage is applied to the flame

rod.

Because of the high impedance the flame rod connection is

safely accesible according to EN 60730.

Since the flame sensing input is very sensitive and the

current detection threshold is only a few tenths of microamp,

care must be taken that no spurious current flows.

The flame rod wire must have creepage to earth of at least 10

mm.

Contacts of the flame rod wire must not be imposed to fluids

or dirt.

Short

µ

A meter during ignition, to prevent damage of

the

µ

A meter in single rod application.

WARNING