S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

69-1299

10

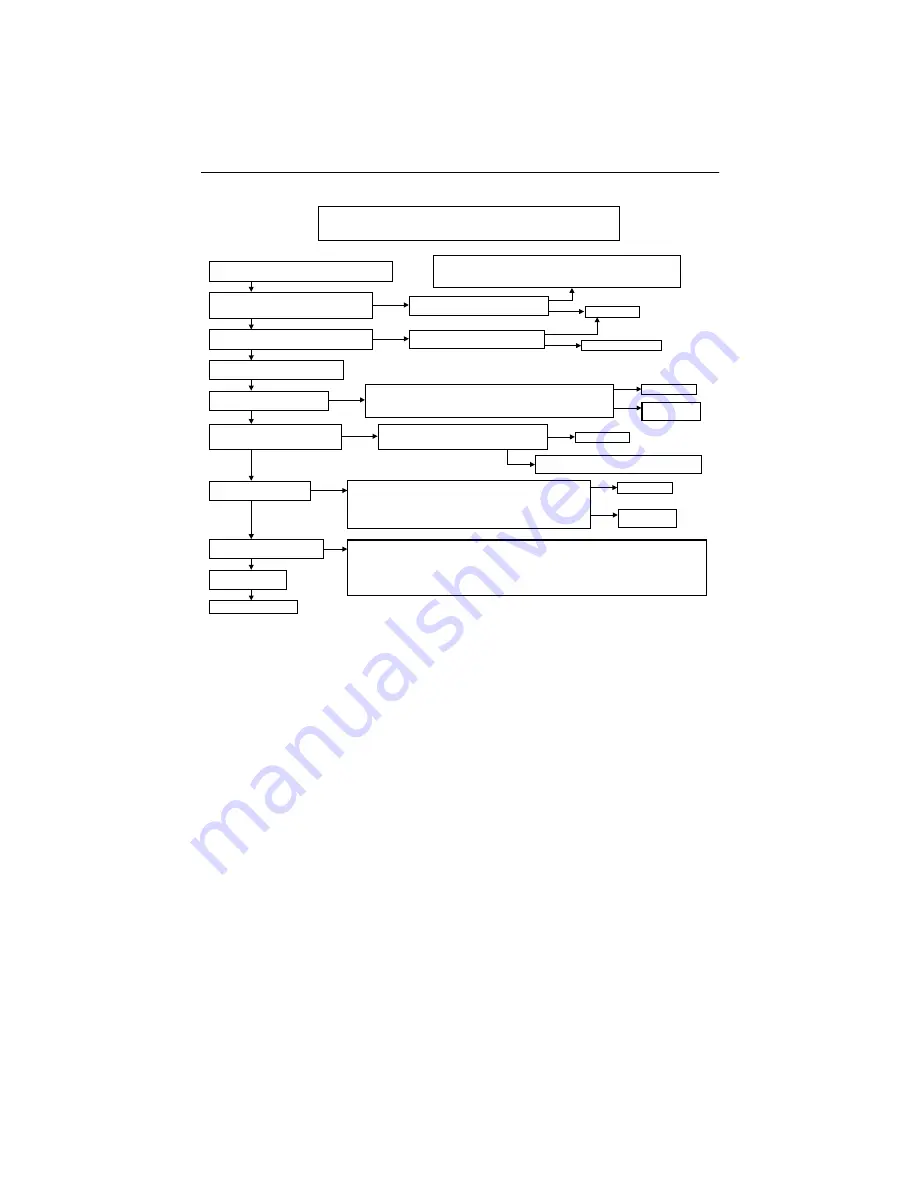

Fig. 9. S8700 Direct Spark Ignition system troubleshooting guide.

M16663

NOTE: BEFORE STARTING TO TROUBLESHOOT THIS SYSTEM:

1. UNDERSTAND THE APPLIANCE SEQUENCE OF OPERATION AS DEFINED BY THE APPLIANCE

MANUFACTURER.

2. ASSURE APPLIANCE INPUT POWER SUPPLY AND GAS SUPPLY ARE CORRECT AND TURNED ON.

WITH APPLIANCE POWERED AND GAS SUPPLY ON, SET

TEMPERATURE CONTROL TO GENERATE A CALL FOR HEAT

LED FLASHES SHOWING S8700 IS POWERED. [LED

FLASHES QUICKLY FOR A SHORT TIME AT START UP,

THEN MOVES TO STEADY ON/OFF PATTERN]

LED FLASHES STEADY ON/OFF CONFIRMING

SAFE START CHECK COMPLETED SUCCESSFULLY.

WAIT FOR PREPURGE DELAY [S8700J, K, L,

M MODELS ONLY – 30 SECONDS TYPICAL]

SPARK OUTPUT ENERGIZED; STRONG

SPARK AT SPARK ELECTRODE

MAIN BURNER GAS CONTROL ENERGIZED.

MAIN BURNER LIGHTS DURING TRIAL FOR

IGNITION.

MAIN BURNER STAYS ON WHEN

TRIAL FOR IGNITION ENDS.

MAIN BURNER STAYS ON THROUGH

END OF CALL FOR HEAT.

CALL FOR HEAT ENDS.

SYSTEM SHUTS OFF.

TROUBLESHOOTING ENDS.

CHECK AND REPAIR LINE VOLTAGE POWER, LOW VOLTAGE TRANSFORMER, LIMIT

CONTROLLERS, THERMOSTATS, WIRING, COMBUSTION AIR BLOWERS AIRFLOW

PROVING SWITCHES AND OTHER CONTROL COMPONENTS THAT PREVENT

POWER FROM REACHING THE IGNITION CONTROL. SEE FIG. 2 AND 3.

CONFIRM 24 VAC BETWEEN THE 24 VAC AND

THE 24 VAC (GND) TERMINALS OF S8700.

IF CONTROL LOCKS OUT [LED ON STEADY],

CHECK FOR FLAME AT MAIN BURNER.

REPLACE S8700

REPLACE S8700

REPLACE S8700

REPLACE S8700

REPLACE GAS CONTROL

IF S8700 GOES INTO LOCKOUT, RESET SYSTEM.

CHECK ALL IGNITION CABLE, BURNER GROUND WIRING, AND CERAMIC

INSULATION FOR LOOSE CONNECTIONS, POOR INSULATION, CRACKING, AND

MOISTURE. CHECK THAT SPARK GAP IS NOT TOO SMALL OR TOO LARGE. ALL OK?

REPAIR/REPLACE

AS NECESSARY

REPAIR/REPLACE

AS NECESSARY

IF S8700 GOES INTO LOCKOUT, RESET SYSTEM.

CHECK FOR 24 VAC BETWEEN S8700 VALVE AND

VALVE (GND) TERMINALS DURING TRIAL FOR IGNITION.

CHECK GAS SUPPLY, GAS CONTROL, AND GAS

CONTROL WIRING. REPAIR/REPLACE AS NECESSARY.

IF S8700 GOES INTO LOCKOUT, RESET SYSTEM.

CHECK ALL IGNITION CABLE, BURNER GROUND WIRING, AND CERAMIC

INSULATION FOR LOOSE CONNECTIONS, CRACKING, SHORTS TO APPLIANCE

CHASSIS. CHECK FLAME ROD FOR CONTAMINATION, DAMAGE, CONTACT WITH

BURNER. CONFIRM THAT MAIN FLAME ENVELOPES THE FLAME SENSE ROD

AND BURNER GROUND TO ALLOW PROPER FLAME SENSE. ALL OK?

IF S8700 GOES INTO LOCKOUT, RESET SYSTEM.

CONFIRM 24 VAC BETWEEN THE 24 VAC AND 24 VAC (GND) TERMINAL ON S8700. CHECK FLAME ROD, FLAME ROD

WIRING, AND BURNER GROUND FOR GOOD CONNECTION. ALSO CHECK FLAME ROD INSULATORS AND WIRING

FOR EXCESSIVE HEAT. TEMPERATURES ABOVE 1000F CAN CAUSE BREAKDOWN IN CERAMIC INSULATION.

NOTE: IF BURNER GROUND IS POOR OR ERRATIC, OR LEADWIRE OR CERAMIC TEMPERATURES ARE TOO HIGH,

SHUTDOWNS MAY OCCUR EVEN IF OPERATION IS NORMAL AT TIME OF CHECKOUT. THIS TYPE OF SITUATION IS

HIGHLY UNLIKELY TO BE CAUSED BY THE S8700 CONTROL. REPAIR/REPLACE FLAME ROD AND WIRING AS NECESSARY.

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NOTES:

– B, D, J AND K MODELS GO THROUGH ONE TRIAL FOR IGNITION PERIOD BEFORE LOCKOUT.

– E, F, L AND M MODELS GO THROUGH THREE TRIAL FOR IGNITION PERIODS (WITH A 30 SECOND

INTERPURGE PERIOD BETWEEN EACH TRIAL FOR IGNITION.) BEFORE LOCKOUT CONTROL STARTS

ANOTHER IGNITION SEQUENCE AUTOMATICALLY AFTER ONE HOUR.

– CONTROL IS IN LOCKOUT WHEN VALVE IS CLOSED, SPARK IS OFF, ALARM IS ACTIVATED AND

LED IS ON STEADY. ON E, F, L, M MODELS, ONE HOUR AUTO RESET TIMER IS ALSO ACTIVATED.

REPEAT PROCEDURE UNTIL TROUBLE-FREE OPERATION IS OBTAINED.

Summary of Contents for S8700 Series

Page 11: ...11 69 1299 ...