S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

69-1299

4

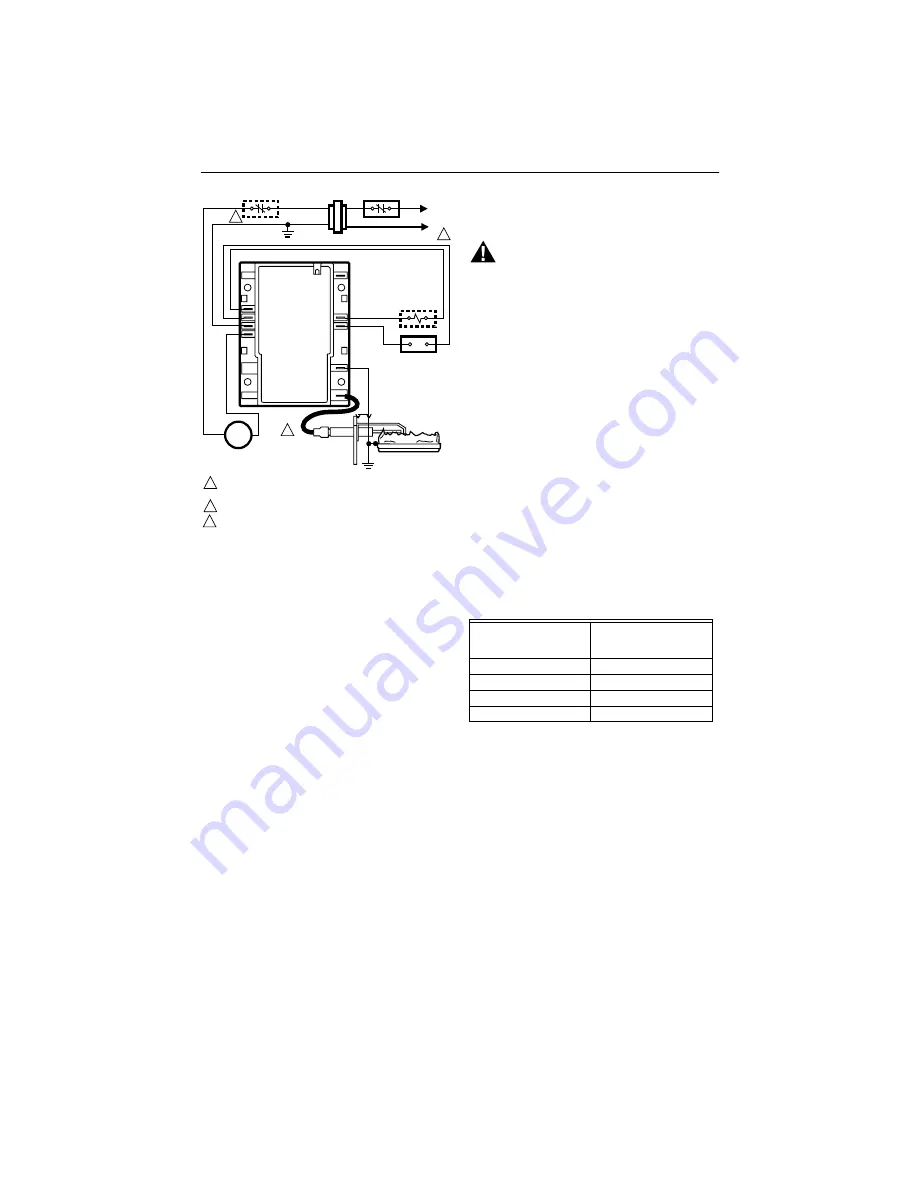

Fig. 3. Typical wiring diagram for

S8700E,J,L single rod models.

NOTE:

NOTE: Proper system operation requires that

the S8700 GND (Burner) terminal is wired to

be electrically common with the spark

electrode bracket, flame sensor bracket (if a

separate flame sensor is used) and the main

burner. In many applications, this is

accomplished through connecting the S8700

GND (Burner) terminal to the appliance

chassis, as the other noted components are

presumed to be electrically common with the

appliance chassis. If flame sensing problems

are noted, it may be due to corroded or loose

electrical connections between the noted

components and the appliance chassis.

STARTUP

The following start-up procedures are basic to all S8700

controls. If this is a replacement application, refer to the

specific instructions provided by the heating appliance

manufacturer, if available. Also, since the auxiliary

controls used on any DSI system can differ, refer to the

manufacturer’s instructions for start-up and checkout

procedures for other system components.

NOTE:

If the S8700 does not perform as outlined in

the following Start System and Check Trial for

Ignition steps, refer to the Service section to

determine the cause.

Gas Leak Test

If the gas control has been replaced as a part of the S8700

installation, perform the following test for gas leaks.

WARNING

Explosion or Fire Hazard.

Gas Leaks can cause property damage,

severe injury or death.

To avoid possible explosion or fire, perform the

Gas Leak Test.

With the main burner in operation, paint the pipe joints

and valve gasket with a rich soap and water solution.

Bubbles indicate a gas leak. To stop a leak, tighten the

joints and screws. Never use a flame to check for gas

leaks.

Start System

1.

Turn on the power and the gas supply.

2.

Set the temperature control to call for heat and

watch for a spark at the igniter (S8700B,D,E,F

models have no delay on start-up; S8700J,K,L,M

models have a predetermined delay on start-up

for prepurge).Check that the system starts as

follows: Prepurge delay (if provided), spark turns

on, gas valve opens at once and burner ignites

after gas reaches the main burner. Once the

burner flame is established, spark igniter cuts off.

NOTE:

NOTE: If the gas control has been replaced or

serviced, lightoff may not be satisfactory until

air has been purged from the gas line or the

gas input and combustion air have been

adjusted (see manufacturer’s instructions).

Table 3. S8700 Trial for Ignition Periods.

Check Trial for Ignition

1.

Check device label on the control to determine

the correct trial for ignition time.

2.

With the system power off and the thermostat or

temperature control set to call for heat, manually

shut off the gas supply.

3.

Turn power on to energize the S8700 and

immediately start timing when the gas valve is

energized.

4.

Determine the number of seconds to drop-out of

the gas valve. It should not exceed the trial for

ignition time shown in Table 5.

5.

After spark cutoff, manually reopen the gas sup-

ply cock. No gas should flow to the main burner.

6.

Reset the system as described in Resetting

S8700 After Safety Lockout section.

Q347

SPARK

IGNITER

BURNER

IGNITER AND

BURNER GROUND

L1

(HOT)

L2

1

2

3

1

2

3

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 6 FT (1.8 M).

S8700E,J,L CONTROL

ANY COMBINATION

GAS CONTROL

2.0A MAX.

TEMPERATURE

CONTOL

LIMIT CONTROLLER

TRANSFORMER

M16528

FLAME

SENSE

ALARM

VALVE

GND

VALVE (GND)

24 Vac (GND)

24 Vac

BURNER

(GND)

SPARK

ALARM, IF USED

Specified Trial for

Ignition (TFI) (stamped

on control)

Trial for Ignition Should

Not Exceed

4.6 sec

5.0 sec

6.6 sec

7.0 sec

11.1 sec

11.5 sec

21.1 sec

21.5 sec

Summary of Contents for S8700 Series

Page 11: ...11 69 1299 ...