S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

69-1299

8

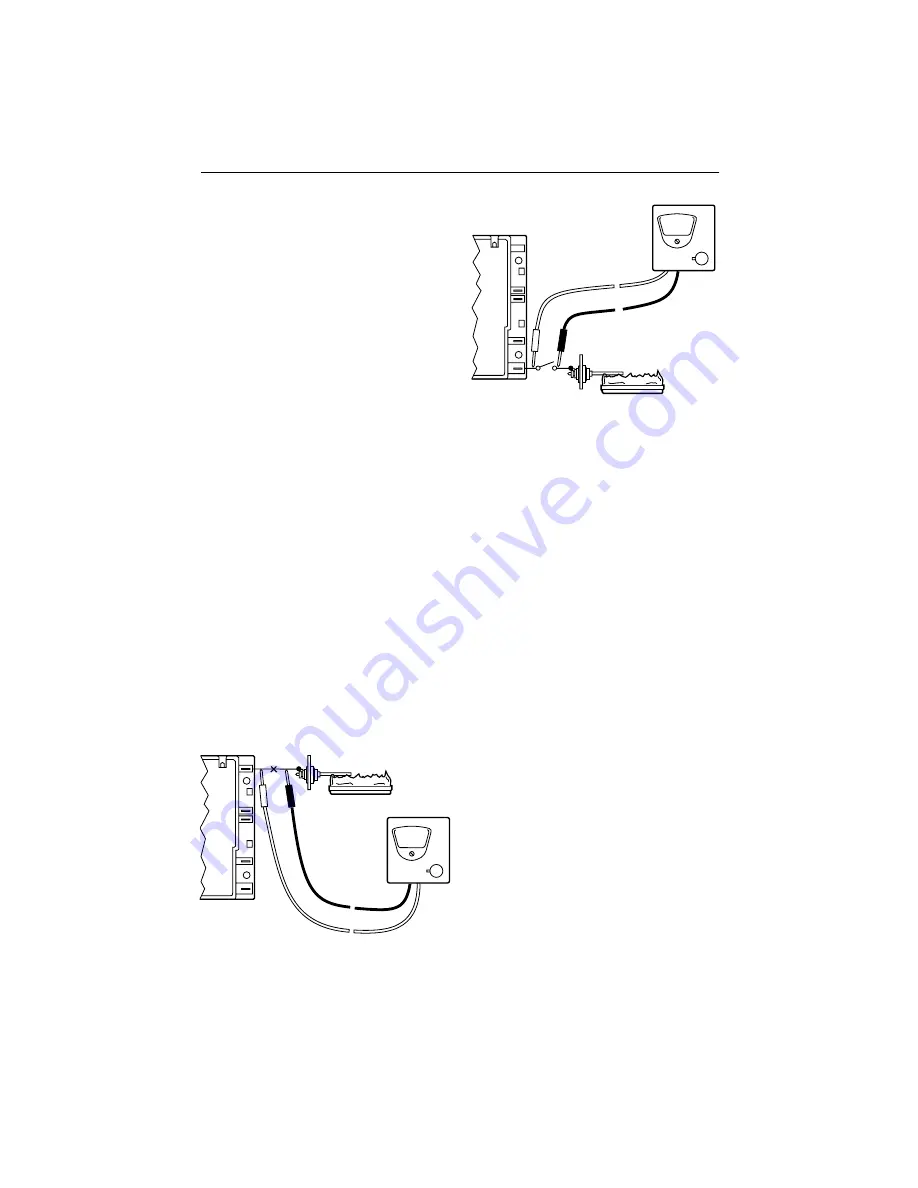

Check the flame sensing current from the sensor to the

S8700 as follows:

For S8700D,F,K,M:

1.

Connect an analog meter (dc microammeter

scale) in series with the flame sense lead as

shown in Fig. 6. Use the Honeywell W136A test

meter or equivalent. Disconnect the flame sense

wire from the sense terminal on the control. Con-

nect the red (positive) meter lead to the flame

sense terminal on the control. Connect the black

(negative) meter lead to the flame sense wire

leading to the flame rod.

2.

Restart the system and read the meter. The flame

sense current should be at least 2.0

µ

A and

steady to assure reliable appliance operation. If

the reading is less than 2.0

µ

A or unsteady, See

the Low Or Unsteady Flame Current section. If

flame is present at the sensor and a reading of

0

µ

A is obtained, check for damaged insulation or

ground path in the flame sensor wiring. Also

check for damaged, wet or dirty ceramic in the

flame sensor assembly.

For the S8700B,E,J,L:

1.

Connect a switch between the S8700 spark termi-

nal and the spark cable. See fig. 7.

2.

Attach meter leads on each side of the switch .

3.

Light burner with the switch closed, then open the

switch to read flame current.

IMPORTANT

Do not let spark energy enter the meter or

damage can result.

LOW OR UNSTEADY

FLAME CURRENT

If the current to the S8700 is less than 2.0

µ

A or is

unsteady, check the burner flame, flame sensor location

and electrical connections as described in the following

sections.

Fig. 6. S8700D,F,K,M dual-rod

flame current measurement.

Fig. 7. S7800B,E,J,L single rod

flame current measurement.

Burner Flame

The flame sensor must be constantly immersed in

flame. Check the burner flame conditions as shown in

Fig. 7.

NOTE:

Note:If the main burner flame is fluctuating or

lifting off the main burner, intermittent flame

signals can be generated. Adjust the appliance

so that the main flame is steady and not lifted

from the main burner.

Flame Sensor

The flame signal is best when about 1 in. (25 mm) of

flame rod is immersed in the burner flame. A bent flame

rod, bent mounting bracket or cracked ceramic insulator

can affect flame signal. A cracked ceramic insulator

may perform properly when cold, but can cause inter-

mittent operation when it heats up. Replace flame

sensor if necessary.

Electrical Connections and Shorts

All wiring must be in good condition; replace if insulation

shows any sign of damage. Connections at the S8700

and the flame sensor must be clean and tight. Wiring

between the main burner and the S8700 GND (burner)

terminal must also be in good condition. A jumper

between the GND (burner) terminal and the main burner

will often confirm if the flame circuit wiring needs atten-

tion. If wiring needs replacement, use moisture resistant

No. 18 wire rated for continuous duty up to 221

°

F

(105

°

C).

ALARM

VALVE

(GND)

SPARK

SENSE

RED (+)

BLACK (–)

ANALOG METER

DC MICROAMP

SCALE (MUST READ

TO 0.1 uA dc)

2.0

µ

A dc MINIMUM (AND STEADY)

M16236B

FLAME

SENSOR

BURNER

ALARM

VALVE

(GND)

SPARK

RED (+)

BLACK (–)

2.0

µ

A dc MINIMUM (AND STEADY)

M16664

FLAME

SENSOR

BURNER

SWITCH

ANALOG METER

DC MICROAMP

SCALE (MUST READ

TO 0.1 uA dc)

Summary of Contents for S8700 Series

Page 11: ...11 69 1299 ...