69-1174

10

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

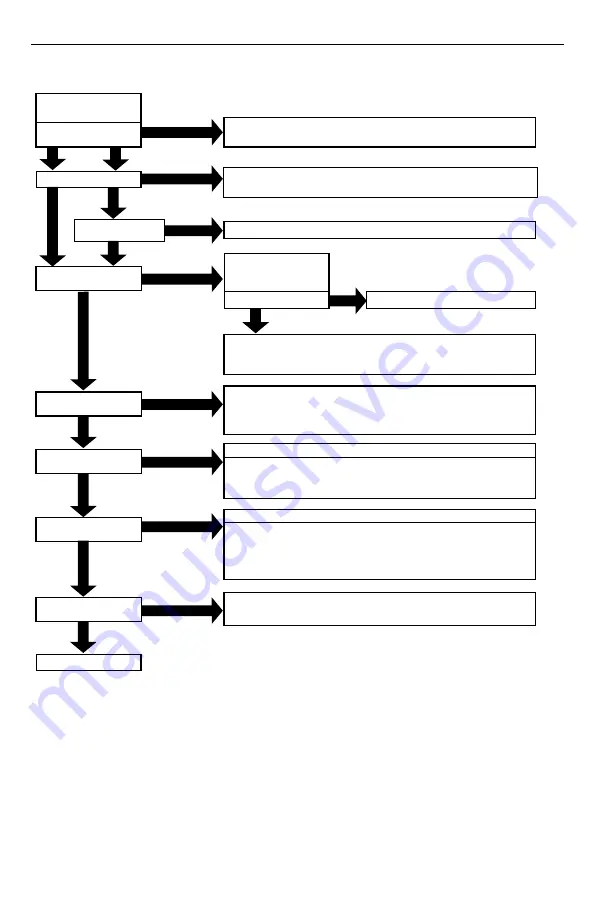

START

SPARK STOPS WHEN

BURNER IS LIT

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS

CALL FOR HEAT ENDS:

SYSTEM SHUTS OFF

TROUBLESHOOTING ENDS

TURN THERMOSTAT TO

CALL FOR HEAT

TURN GAS SUPPLY OFF.

POWER TO UNIT

(24 VAC NOMINAL)

SAFE START CHECK OK.

J, K, L, AND M MODELS

PREPURGE DELAY.

CHECK LINE VOLTAGE POWER, LOW VOLTAGE TRANSFORMER, LIMIT CONTROLLERS,

THERMOSTATS AND WIRING. ALSO, AIR PROVING SWITCH ON PREPURGE

SYSTEMS (SEE FIGS. 4 AND 5).

UNIT LOCKS OUT ON POWER UP. CHECK FOR FLAME AT EACH BURNER. IF FLAME

IS PRESENT, SHUT OFF GAS SUPPLY AND REPLACE GAS CONTROL. IF NOT, REPLACE

IGNITION CONTROL.

SPARK ACROSS IGNITER OR

IGNITER/SENSOR GAP.

NO PREPURGE DELAY. REPLACE J, K, L, OR M UNIT.

M18059

NOTE: BEFORE TROUBLESHOOTING, FAMILIARIZE YOURSELF

WITH THE START-UP AND CHECKOUT PROCEDURE.

•

TURN OFF GAS SUPPLY.

•

PULL IGNITION LEAD

AND CHECK SPARK AT

SPARK TERMINALS.

SPARK OKAY?

•

CHECK IGNITION CABLE, BURNER GROUND WIRING, CERAMIC INSULATOR AND GAP,

AND CORRECT.

•

CHECK BOOT OF THE IGNITION CABLE FOR SIGNS OF MELTING OR BUCKLING. TAKE

PROTECTIVE ACTION TO SHIELD CABLE AND BOOT FROM EXCESSIVE TEMPERATURES.

•

CHECK FOR 24 VAC ACROSS VALVE AND VALVE TERMINALS DURING TRIAL FOR

IGNITION PERIOD. IF NO VOLTAGE, REPLACE UNIT.

•

Q347, Q354 OR Q366 MAY BE OUT OF POSITION.

•

CHECK ELECTRICAL CONNECTIONS BETWEEN UNIT AND GAS CONTROL. IF OKAY,

REPLACE GAS CONTROL.

NOTE: IF UNIT GOES INTO LOCKOUT, RESET SYSTEM.

•

CHECK CONTINUITY OF SENSOR CABLE(S) AND GROUND WIRES.

NOTE:

IF GROUND IS POOR OR ERRATIC, SHUTDOWNS MAY OCCUR OCCASIONALLY

EVEN THOUGH OPERATION IS NORMAL AT TIME OF CHECKOUT.

•

CHECK FOR EXCESSIVE HEAT AT SENSOR INSULATOR(S)

(TEMPERATURE ABOVE 1000

°

F (538

°

C) CAUSES SHORT TO GROUND).

•

IF CHECKS ARE OKAY, REPLACE UNIT.

NOTE: IF UNIT GOES INTO LOCKOUT, RESET SYSTEM.

•

CHECK CONTINUITY OF SENSOR CABLE(S) AND BURNER GROUND WIRES.

•

CHECK THAT BURNER FLAME COVERS ALL ELECTRODES (ON BOTH BURNERS IF S8702).

•

CHECK 24V GROUND CONNECTION TO BURNER.

•

IF CHECKS ARE OKAY, REPLACE UNIT.

•

CHECK FOR PROPER TEMPERATURE CONTROLLER OPERATION.

•

REMOVE VALVE LEAD AR UNIT; IF VALVE CLOSES, RECHECK TEMPERATURE

CONTROLLER AND WIRING; IF NOT, REPLACE GAS CONTROL.

REPLACE UNIT

REPEAT PROCEDURE UNTIL TROUBLE FREE OPERATION IS OBTAINED.

NOTES: B, D, J, AND K MODELS GO THROUGH ONE (1) TRIAL FOR IGNITION PERIOD BEFORE LOCKOUT.

E, F, L, AND M MODELS GO THROUGH THREE (3) TRIAL FOR IGNITION PERIODS WITH A 30 SECOND

INTERPURGE PERIOD BETWEEN TRIAL FOR IGNITION PERIODS BEFORE LOCKOUT AND THEN RETRY AUTOMATICALLY

AFTER ONE (1) HOUR.

LOCKOUT = VALVE CLOSED PLUS SPARK OFF PLUS ALARM ACTIVATED PLUS LED ON STEADY.

S8702 MODELS SPARK AND SENSE FLAME ON TWO SEPARATE BURNERS.

FLAME MUST BE SENSED ON BOTH BURNERS DURING TRIAL FOR IGNITION ON THE UNIT WILL LOCKOUT.

MAIN BURNER(S) LIGHTS

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

Fig. 9. S8701/S8702 Direct Spark Ignition System Troubleshooting Guide