69-1174

2

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

a

Valve used must be designed for DSI application.

b

Separate spark igniter and flame sensor mounted on a

common bracket.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazard-

ous condition.

2. Check the ratings given in the instructions and on

the product to make sure it is suitable for your

application.

3. The installer must be a trained, experienced service

technician.

4. After installation is complete, check out system

operation.

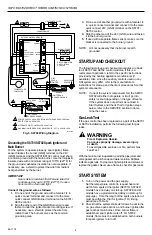

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

If a new gas control is to be installed, turn off gas

supply before starting installation.

Be sure to conduct a gas leak test after the control

is installed.

CAUTION

Electric Shock Hazard.

Can cause personal injury or equipment

damage.

Disconnect power supply before wiring.

Model

No.

Spark

Igniter

Flame

Sensor

Valve Required

a

S8701/

Q347A

Q354A

Honeywell VR8205

S8702

Q366

b

gas valves or

equivalent

Heat

Excessively high temperatures can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control, see Table

2. If the appliance operates at very high temperatures, use

insulation, shielding, and air circulation, as necessary, to

protect the control. Proper insulation or shielding should be

provided by the appliance manufacturer; verify proper air

circulation is maintained when the appliance is installed.

Table 2. S8701/S8702 Ambient Temperature Ratings.

IMPORTANT

If this is a replacement application, follow the

appliance manufacturer’s instructions, if avail-

able. The manufacturer usually provides wiring

diagrams, start-up and checkout instructions and

the service procedures for their system. If the

manufacturer’s instructions are not available, this

information may be used as a general guide.

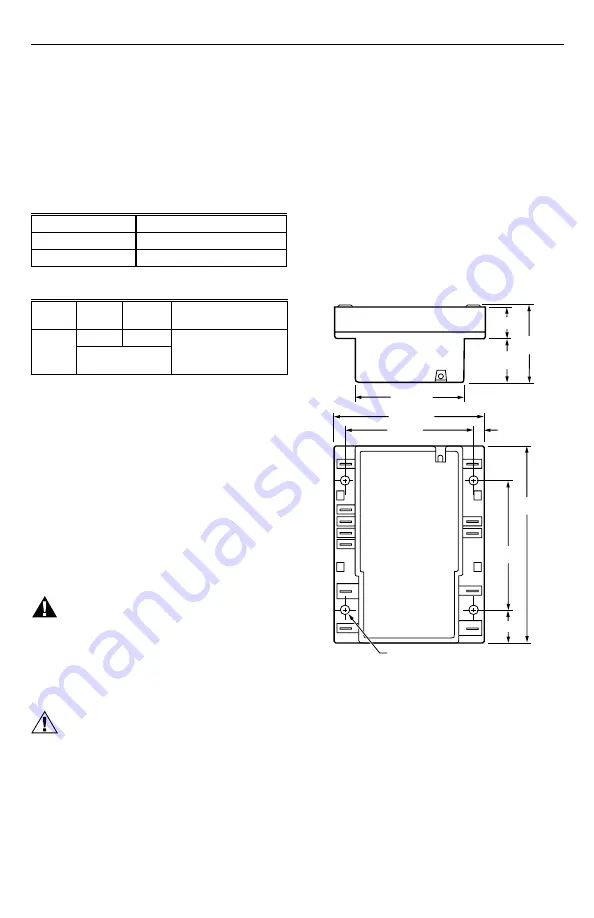

Mounting The S8701/S8702 Control

Select a location within 6 ft (1.8m) of the burner that will

permit a direct cable route to the spark igniter terminal.

Ready access to the terminals is necessary for wiring and

servicing. The S8701/S8702 control may be mounted in

any position. Use No. 6-32 machine screws or No. 8

sheetmetal screws 1 inch long for fastening. Fasten

securely. Do not exceed the ambient temperature rating

given in Table 2.

M16233

13/16 (21)

1-1/8

(29)

2

(50)

2-13/16 (72)

3-15/16 (100)

3-3/8 (86)

3-3/8

(86)

5/17 (7)

7/8 (23)

5-3/16

(130)

3/16 (4)

Operation

Ambient Temperature

50 Hz

-40

°

F to 160

°

F

60 Hz

-40

°

F to 175

°

F

Table 3. System Requirements.

Fig. 1. S8701/S8702 Dimensions.

Mounting Auxiliary Controls

Mount the spark igniter, flame sensor, temperature control,

transformer, gas control and any other auxiliary controls

according to the manufacturer’s instructions.

NOTE:

The S8701 and S8702 installations require a 24V

transformer rated to handle both the S8701/

S8702 current and the gas valve current. Table 4

shows the transformer rating necessary for

various loads.