69-1174

5

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

NOTE:

If the gas control has been replaced or serviced,

lightoff may not be satisfactory until air has been

purged from the gas line or the gas input and

combustion air have been adjusted (see

manufacturer’s instructions).

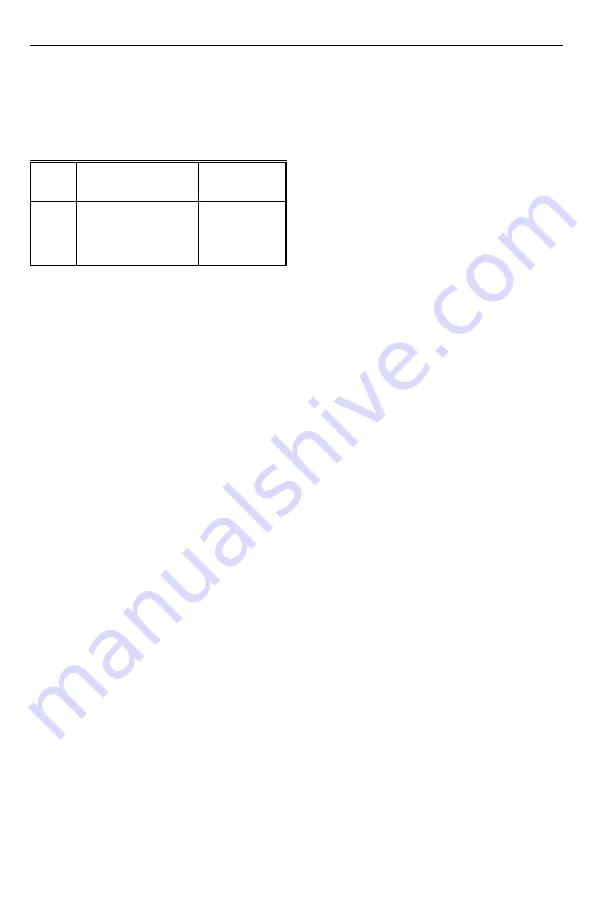

Table 6. Trial for Ignition Periods for the S8701/S8702.

Check Trial for Ignition

1. Check device label on control to determine correct

Trial for Ignition time.

2. With the system power off and the thermostat or

temperature control set to call for heat, manually

shut off the gas supply.

3. Turn power on to energize the S8701/S8702,

immediately start timing when the gas valve turns

on.

4. Determine the number of seconds to drop-out of the

gas valve. It should not exceed the trial for ignition

time shown in Table 6.

5. After spark cutoff, manually reopen gas supply cock.

No gas should flow to the main burner.

6. Reset system as described below.

Resetting S8701 and S8702 After Safety

Lockout

If the control goes into safety lockout, it will remain locked

out for D and K models, until the system is reset.

To reset the system:

Adjust the temperature control setting to below room

temperature, wait 5 seconds, and move the temperature

control setting up to request heat or remove 24V power

and reapply. Normal ignition should occur as described in

Start System section.

NOTE:

F and M models have the 3 retry feature for Trial

for Ignition with 30 second interpurge between

TFI periods. Safety lockout on the F and M

models occurs after the 3rd TFI period if flame is

not sensed. F and M models also automatically

reset after one (1) hour in lockout.

CHECKOUT

Start the system and observe operation through at least

one complete cycle to make certain all controls are

operating safely.

Sequence of Operation

The S8701/S8702 controls perform the following basic

functions:

•

Supplies power to the electronic pulse-generator

circuit for the spark igniter (14,000 volts, open circuit).

•

Allows up to 23.75 seconds (maximum) for ignition

and 1 or 3 trials before system safety lockout occurs

(see Table 4).

•

Senses burner flame for safe lighting (2 burners for

S8702).

•

Shuts off spark after burner is lit.

The S8701 and S8702 are powered by a 24 Vac trans-

former and activated when the temperature control

requests heat.

Operation is as follows:

When the S8701/S8702 control is activated by the

temperature control’s request for heat, S8701/S8702

controls perform a safe-start check that determines proper

operation of the control before beginning the normal

sequence of operation. Once the Safe Start Check

operation passes, the control turns on the spark circuit and

at the same time, the S8701/S8702 opens the gas

control’s main valves, which allows gas to flow to the main

burner.

Power is supplied to the generator until:

•

The main burner(s) lights and the flame sensor

current reaches 1.0

µ

A, or

•

The ignition activation period ends

If the main burner lights, a flame sensing circuit is com-

pleted through the flame to the burner head to ground.

This current flow sets the Trial for Ignition timer to the reset

(normal) condition and interrupts the spark ignition circuit

(flame sense must occur on both burners on a S8702).

Should the current flow be interrupted, i.e., flame out

condition, the trial for ignition period begins again.

The S8701/S8702 will keep the gas control main valve

open as long as there is a request for heat and flame

current through the flame sensing circuit. If, however, the

trial for ignition timing period ends before the main burner

lights or the flame sensor establishes enough current, the

system will go into safety lockout or interpurge if the

control is an F or M model.

When the system goes into safety lockout, power to the

spark generator is interrupted, the power to the gas valve

is interrupted and the alarm circuit is completed and the

LED is steady on. The system will stay locked out until it is

reset by moving the temperature control setpoint to below

room temperature, no request for heat, for 5 seconds.

Then, re-energize the system by moving the temperature

control setpoint 5

°

F (3

°

C) above room temperature. Or,

remove 24 Vac power to the control then reapply.

NOTE:

F and M models will automatically reset from

lockout after one (1) hour.

Model

Specified Trial for

Ignition (TFI) (stamped

on control)

Trial for

Ignition Should

Not Exceed

S8701;

S8702

4.6 sec

6.6 sec

11.6 sec

21.6 sec

5.05 sec

7.25 sec

12.75 sec

23.75 sec