INSTALLATION INSTRUCTIONS

69-2807-01

S9240F2051 Modulating Integrated

Furnace Control

APPLICATION

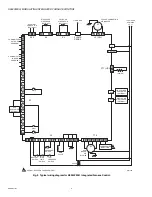

The S9240F2051 Integrated Furnace Control (IFC) is

designed specifically to work with an Allied variable firing rate,

high efficiency furnace. It provides gas ignition, safety shutoff,

and variable speed fan control with multi-firing rate gas

heating and up to 2-stage electric cooling applications.

The S9240F2051 IFC is designed to work with:

• A Conventional thermostat (one or two stages) with or

without a non-communicating outdoor unit (heat pump or

A/C).

• An Allied communicating thermostat and non-

communicating outdoor unit (one or two stages).

• An Allied communicating thermostat and communicating

outdoor unit (one stage, multistage, or modulating).

NOTE: When configured in a communicating system,

the IFC is able to communicate alarms, demands

for heat/cool/dehumidification/etc., and other

information to other components in the system.

Refer to the documentation for complete details

including operating mode sequences.

FEATURES

The S9240F2051 provides the following features:

• Monitors a single stage or 2-stage conventional low

voltage thermostat for requests for heat, cool, or fan.

• Monitors an input provided for connection to a

thermostat with a dehumidification output.

• Provides three stage furnace input rate control when

operating with a conventional single stage thermostat.

• Provides 2-stage or modulating furnace input rate

control based on field selected option when operating

with a conventional 2-stage thermostat.

• Provides full modulating rate (between 40% and 100%

of furnace input) in response to an Allied

communicating thermostat.

• Manages ignition of a main burner flame up to 400,000

BTU per hour using a 120 Vac hot surface igniter.

• Monitors the appliance pressure, limit, and rollout

switches and generate control actions as programmed.

• Controls the 24 Vac Honeywell amplified gas/air gas

valve.

• Controls a 3-phase 120 Vac inducer motor (Fasco

Model 92B1 or other with identical voltage/frequency

curve) and blower assembly based on heat demand

and other parameters.

• Controls the Regal Beloit or Nidec ECM circulator

motor and blower based on defined appliance CFM

profiles

and/or a discharge air sensor signal.

• Controls single stage or 2-stage cooling equipment.

The outdoor unit is controlled directly by the 24 Vac

conventional thermostat inputs. The IFC manages the

circulator speed based on cool demand and other

parameters.

• Controls a 120 Vac humidifier output and a 120 Vac

EAC output. Optionally, controls a 24 Vac low voltage

humidifier.

• Operates with 120 Vac single phase, 60 Hz power

supply.

• Uses a 7-segment LED display to communicate error

code and status information. A single on board button

is provided to generate the desired information

display.

• Field selectable DIP switches to select field specific

control operating parameters such as type of

thermostat, delay timings, and fan operating

parameters.

• On-board jumpers that can be clipped to permanently

enable 2-stage cooling, heat pump compatibility,

dehumidification sequences, and define appliance

characteristics for field replacement purposes.

• Field Test Mode and Diagnostic Recall Mode to assist

the installation/service technician.

• Stores the 10 most recent error codes, which are

accessible by the service technician in Diagnostic

Recall Mode.

• Communications mode using an Allied communicating

thermostat.

• On-board relays (Y1 and Y2) to control a 2-stage

compressor when using the communications mode

with an Allied communicating thermostat.