S9240F2051 MODULATING INTEGRATED FURNACE CONTROL

15

69-2807—01

— If the calibration is unsuccessful, the IFC flashes an

LED error code indicating an unsuccessful calibration

and begins a five minute delay.

• The IFC attempts the calibration routine three more

times (four total) before entering a one hour Soft

Lockout.

• This process repeats until the calibration routine is

successful or the call for heat ends.

— If the low pressure switch opens for less than two

seconds during Prepurge or Igniter warm-up:

• The IFC completes the ignition sequence.

• If the appliance fails to light after the maximum

number of retries has been exceeded, the IFC

proceeds to Soft Lockout and attempts the

pressure switch calibration routine.

— If the low pressure switch opens for longer than two

seconds during Trial for Ignition or normal operation

(Run Mode):

• The IFC proceeds to Postpurge followed by the

vent calibration sequence, before attempting the

ignition sequence again.

• The IFC flashes an LED error code indicating the

pressure switch failed open until the vent calibration

sequence begins.

See Table 12 on page 27 for LED error code and lockout

information.

High Pressure Switch Operation

(during heat cycle)

The high pressure switch determines the inducer speed

required to achieve the high firing rate of the appliance. The

determination is made by the IFC during the calibration

process.

The high fire pressure switch should remain closed during

high fire operation.

— If it opens during high fire operation, the IFC increases

the inducer speed, up to the maximum allowed RPM,

in an attempt to re-close the high pressure switch.

— If the high pressure switch re-closes successfully, the

IFC completes the Heat mode, and performs the vent

calibration on the next call for heat.

— If the high pressure switch remains open, the IFC ends

the call for heat and performs the pressure switch

calibration routine.

The high pressure switch check takes place during calibration.

If the switch is stuck open or closed, calibration will not be

completed and the IFC flashes an error code.

See Table 12 on page 27 for LED error code and lockout

information.

Hot Surface Igniter (HSI) Control

The Hot Surface Igniter is voltage controlled to maintain no

more than 120V over a range of 98 to 132V line input. The HSI

warm up time is fixed for all ignition trials. Both the continuity

of the igniter and the ability of the triggering circuit to energize

the igniter are continuously monitored during the Igniter

Warm-up and Ignition Activation periods. If a problem is

detected, the IFC flashes an LED error code.

See Table 12 on page 27 for LED error code and lockout

information.

Humidity Control

Humidity control is available via line voltage or low voltage

operation. Use the correct wiring terminals for your system.

Line Voltage Humidifier

The line voltage humidifier output is energized when either of

the following conditions are met:

— Anytime both the inducer and circulator are energized

and there is no cool request present.

— A request for compressor heat is active.

Low Voltage Humidifier

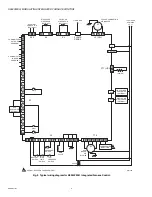

The H terminal on the thermostat block

a

is available for

connection to a 24 volt humidifier. The 24 Vac power is

supplied by the system transformer.

The IFC energizes the H terminal with 24 volts when either of

the following conditions are met:

— Anytime both the inducer and circulator are energized

and there is no cool request present.

— A request for compressor heat is active.

Standard Dehumidification

The dehumidification jumper

b

must be clipped to enable

standard dehumidification.

The DS terminal on the thermostat block must connect to the

dehumidification output on a conventional thermostat.

The IFC varies circulator speed operation based on the DS

signal from the thermostat.

Electronic Air Cleaner

The line voltage EAC output energizes anytime the circulator

is energized, regardless of speed.

Error Conditions

The following section lists the IFC operating sequence for the

stated error conditions.

Main Valve Sensing

The IFC monitors the main valve output at all times.

— If the inducer is off and voltage is detected on the

valve for longer than the fault debouncing time (e.g.

miswire):

• All outputs are turned off except for the inducer,

which energizes at low speed.

• The circulator energizes at the mid heat speed.

• If a call for cool occurs, the IFC energizes the

circulator at the correct cool speed.

a

See “Wiring Connections - Class 2 - Low Voltage.” on

b

See jumper W914 in Table 4 on page 7.