S9240F2051 MODULATING INTEGRATED FURNACE CONTROL

69-2807—01

8

SW2: SEQUENCE

The sequence is factory-set (OFF) to respond to a thermostat

as dictated by the SW1 selection.

The ON position configures the IFC for the Allied modulating

firing state sequence with 2-stage thermostat; and SW1 must

be OFF.

NOTES:

1.

SW2 position is ignored if SW1 is ON.

2.

When used in a communicating system, both

SW1 and SW2 are ignored.

SW3: 2ND STAGE ON DELAY

The On Delay timing applies to systems configured

only

with

single stage thermostats. It is the length of time operating in

normal low fire mode before switching to high fire mode. The

timing is factory-set (OFF) to 7 minutes.

The ON position configures the 2nd stage On Delay for 12

minutes.

NOTE: SW3 position is ignored if SW1 is OFF.

SW4-5: HEAT FAN OFF DELAY

The Heat Fan Off Delay is the period between the loss of

supervised main burner flame after the call for heat has ended

and the deactivation of the blower motor at the low heat

speed. The timing is factory-set (all OFF) to 90 seconds. See

Table 5 for other timing settings.

SW6-7

These two switches are not used.

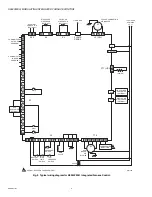

DIP Switch S2 Settings – Cooling Airflow

DIP Switch S2 is used to adjust the cooling speed and profile.

Refer to Fig. 4 on page 7 for location of DIP switch S2.

The default factory settings (all OFF) are shown in Fig. 6 and

indicated in Bold in Table 6.

To change any setting, first disconnect the power, then set

SW8

through

SW13

according to Table 6.

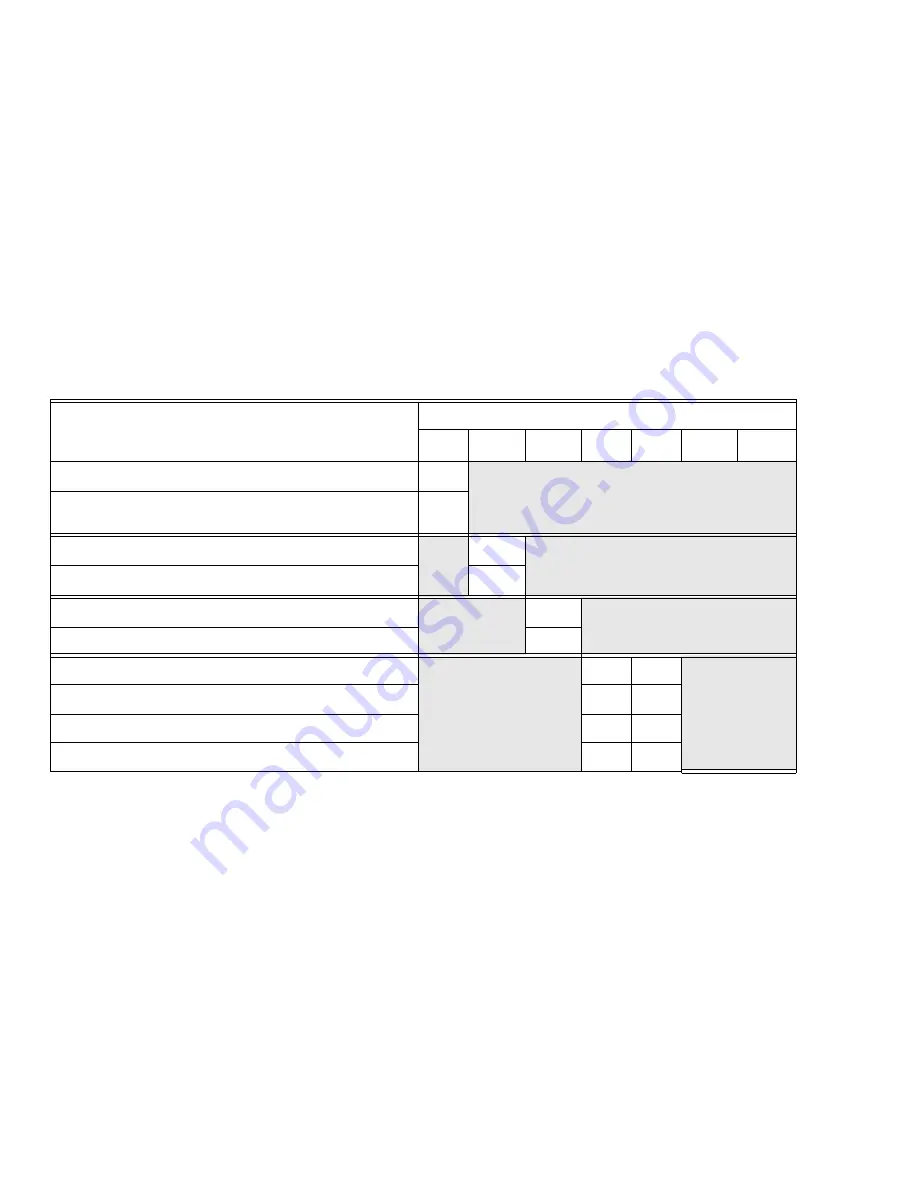

Table 5. DIP Switch S1 Settings - Defaults in Bold.

Description

Individual Switches

SW1

SW2

a

SW3

b

SW4

SW5

SW6

d

SW7

e

2-Stage Thermostat: 2nd and 3rd stage On Delay disabled

OFF

Single Stage Thermostat: 2nd and 3rd stage On Delay

enabled

ON

Conventional 2-stage sequence with 2-stage thermostat

OFF

Special modulating sequence with 2-stage thermostat

c

ON

2nd Stage On Delay - 7 minutes

OFF

2nd Stage On Delay - 12 minutes

ON

Heat Fan Off Delay - 60 seconds

OFF

ON

Heat Fan Off Delay - 90 seconds

OFF

OFF

Heat Fan Off Delay - 120 seconds

ON

OFF

Heat Fan Off Delay - 180 seconds

ON

ON

a

Switch 2 is ignored if switch 1 is in the ON position.

b

Switch 3 is ignored if switch 1 is in the OFF position.

c

When configured with a communicating thermostat, both SW1 and SW2 are ignored.

d

Switch 6 is not used.

e

Switch 7 is not used.