S9240F2051 MODULATING INTEGRATED FURNACE CONTROL

11

69-2807—01

CHECKOUT

Check out the integrated furnace control system:

— At initial installation of the IFC.

— As part of regular maintenance procedures.

— As the first step in troubleshooting.

— Any time work is done on the system.

Use the following procedures only for the integrated furnace

control; see individual component instructions for additional

checkout procedures.

Operation with Allied Communications

When configured in a communicating system, refer to the

Allied documentation for details of the IFC’s operating modes.

The following checkout and operational information applies to

conventional thermostat operations in a non-communicating

environment.

Check Normal Operation

1.

Turn on power to the appliance.

NOTE: Powering up or cycling power will generate the

Pressure Switch Calibration sequence prior to

responding to the call for heat.

2.

Reset the IFC by turning the thermostat to its lowest

setting and waiting five seconds.

3.

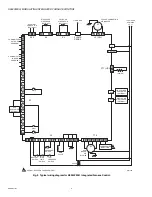

Set the thermostat to call for 1st stage heat. Make sure

the integrated furnace control sequences the system as

indicated in Fig. 9 on page 18 (Fig. 12 on page 21 for

single stage thermostat).

4.

Set the thermostat below the room temperature to end

the call for heat. The burner should go out; the induced

draft fan should provide postpurge time (20 seconds);

and after the delay time, the circulator should stop.

There are several modes of operation. They are discussed in

this section in the following order:

1.

2.

3.

Heat Mode:

a. “Normal Heat Mode - Conventional 2-Stage

Thermostat (standard 2-stage operation selected)”

b. “Modulating Mode - Conventional 2-Stage

Thermostat (special sequence selected)” on

page 13, or

c. “Normal Heat Mode - Conventional Single Stage

4.

5.

NOTE: Compressor heat, Ignition, Retry, Rollout circuit,

Limit switch, Pressure switches, HSI, Humidity

control, and Electronic air cleaner operation are

discussed beginning on page 13.

Pressure Switch Calibration

A system calibration sequence is required prior to normal use

and after AC power is cycled off then on. This process

establishes furnace operating parameters in the specific

installation and provides data to support robust system

operation. The calibration sequence may be repeated at other

times as required to help assure optimum performance.

Calibration is required during the initial start up of the furnace

installation in the field. All fuel, electrical, venting, condensate

drain piping (trap primed), combustion air supplies, as well as

conditioned air ducts and returns should be connected prior to

calibration.

NOTE: The calibration process takes 60 to 120 seconds

to complete successfully. The LED flashes “C A

L” during a the calibration cycle.

Successful Calibration

Calibration data is stored in volatile memory and is used to

determine furnace operation and control parameters in

heating mode. The IFC will not perform additional calibrations

unless required by changes in the appliance’s operating

conditions, if requested by the installer/service person, or by

cycling the power to the furnace.

Unsuccessful Calibration

If the inducer speed limits are reached, and calibration is

unsuccessful, the IFC proceeds to a 5 minute delay and

flashes the appropriate LED error code. The IFC repeats the

calibration sequence four times with a 5 minute delay in

between each try, and if still unsuccessful, the IFC moves to

Soft Lockout.

Calibration Initiation

Calibration initiates by:

• The IFC, on the initial call for heat after power-up.

• The installer/service person as part of the Field Test Mode.

See “Field Test Mode” on page 25.

• The IFC, whenever a venting condition change is detected

including:

— Low pressure switch fails to close during the wait for

low pressure switch to close time. Calibration takes

place immediately.

— Low pressure switch opens for longer than two

seconds during the heating cycle. Heating cycle

includes prepurge, HSI warm up, trial for ignition,

flame stabilization, and run states. Calibration takes

place immediately.

— High Pressure Switch fails to close or open during the

heating cycle at 100% firing rate operation. Calibration

takes place on the next call for heat.

— Ramp down low fire switch check fails. Calibration

takes place on the next call for heat.

The calibration process does not generate any error codes

other than the inducer or pressure switch calibration failures.

However, If either pressure switch closes before the

calibration starts and while the inducer RPM is zero (0), the

pressure switch error is generated.

At the end of a successful calibration, if a call for heat is still

present, the IFC skips the Prepurge and goes straight into HSI

warm-up. This speeds up the heating process and reduces

the excess purge.