3

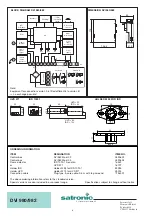

DVI 980/982

3. Lock out and reset

The unit can be reset or brought into lock out mode in two

different ways:

Internal (optional)

In the lock out case the unit can be reset by pushing the

reset button meaning a new start-up cycle is performed.

External

Instead of using the reset lock out button the same

function can be achieved by using an external button which

connects terminal X2/12 with X2/9 (see also circuit and

block diagram).

Models with volatile lock out also can be reset by a short-

time interrupt of the supply line.

If the pushbutton (internal or external) is pressed during

normal operation or during the start sequence for more then

3 sec. and afterwards released, the control box will perform

a shutdown.

Please note

The unit can only be brought to lockout mode or

be reseted if power is applied to the unit.

Don't apply to units with volatile lock out.

4. Low-voltage protection

The mains voltage has to be more than 193 V

eff

in order to

allow the unit to perform a start-up.

The mains voltage is not only monitored in the start-up

phase but also permanently during operation. If the

voltage drops below < 175 V

eff

during start-up or run time

the control box proceed to safety shut-down and goes

into a waiting status. If the voltage rises again, the control

box performs automatically a start-up as soon as the

mains voltage is > 193 V

eff

.

5. Safety

The design and control sequence of the DVI980/982 controls

will comply with the currently applicable standards and

regulations (see also TECHNICAL DATA).

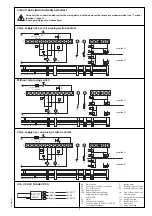

6. Mounting and electrical wiring

The DVI 980/982 is put directly on the solenoid valve.

Molex plug connector 3003 for:

– Power supply line

– Control thermostat RT

– Air proving switch LW

– Motor M

– External lock out signal

– Safety temperature delimiter STB

– External reset and lock out button

Counterpart:

– Molex plug connector 3001

General

The control box and the sensor shall not be exposed to

excessive vibrations.

7. Model functions

The following functions are configured by factory

Model 01:

•

with air proving switch

•

IR-data transmission over Palm Pilot, PC or hand-held

•

non volatile lock out, no reset with interrupt of the supply

line

•

direct lockout after loss of flame during operation

•

direct lockout if no flame established after safety time

•

with internal reset button

•

without potential free output for flame signal

•

Circuit diagram:

"valve supply over air proving switch

contact", variation A, see page 5)

Model 02:

•

with air proving switch

•

IR-data transmission over Palm Pilot, PC or hand-held

•

non volatile lock out, no reset with interrupt of the supply

line

•

altogether 2 times recycling if no flame established after

safety time or loss of flame during operation

•

without internal reset button

•

potential free output for flame signal

•

Circuit diagram:

"valve supply not over air proving

switch contact", variation A, see page 5)

•

with internal lock out lamp (LED)

Model 05:

•

with air proving switch

•

IR-data transmission over Palm Pilot, PC or hand-held

•

volatile lock out, reset with interrupt of the supply line

•

altogether 2 times recycling if no flame established after

safety time or loss of flame during operation

•

without internal reset button

•

potential free output for flame signal

•

Circuit diagram:

"valve supply over air proving switch

contact", variation A, see page 5)

•

with internal lock out lamp (LED)