4

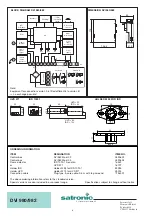

DVI 982/982

INSTALLATION INSTRUCTIONS AND MAINTENANCE

1. Important notes

– The controls must be installed by qualified personnel

only. The relevant national regulations have to be

observed.

– On commissioning the wiring has to be carefully checked

according the appropriate diagram, Incorrect wiring can

damage the unit and endanger the installation.

– The fuse rating has to ensure that the limits specified in

TECHNICAL DATA will not be exceeded. If these

precautions are not observed, the effect of a short circuit

can cause severe damage to the control and installation.

– For safety reasons a minimum of one control shutdown

per 24 hours has to be observed.

– Disconnect the mains before the control box is plugged

in or out.

– The control box is a safety device and must not be

opened!

2. Function control

For safety reasons the flame detection system should be

tested on commissioning the installation as well as after a

service or longer shut-down.

a) Start-up with closed gas valve

– for direct lockout operation, after safety time is over

the unit has to go into lock out mode!

– for recycling operation (max. recycling limited) carry

out a re start-up.

b) Normal start-up, when burner is running, close gas valve

– for direct lockout operation, after loss of flame the

control box has to go into lockout mode!

– for recycling operation (max. recycling limited) carry

out a re start-up.

c) Normal start-up, during pre-purge or operation, interrupt

the air proving switch

– for direct lockout operation, the control box has to go

into lockout mode immediately!

– for recycling operation (max. recycling limited) carry

out a re start-up.

d) Bridged air proving switch before start

– the fan motor switches on for approx. 2 - 3 sec.,

followed by a lockout. After 10 sec., this quick lockout

is resetted by the control box and a second start

attempt follows (fan motor switches on for approx.

2 - 3 sec.). A standard lockout appears if the air

proving switch (LW) contact is still in it’s closed

position (e.g. welded contacts). Has the air proving

switch (LW) changed to it’s open position in the

meantime (e.g. by a run down motor), a normal start

sequence follows.

3. Fault finding

The built-in information system facilitates the trouble

shooting in the case of problems occurring during start-up

or during operation.

A list of possible lock out messages can be found in

APPLICATION FEATURES chapter 1.2.

Please note:

The control box is locked in lock out mode

and the reason for the lock out is displayed

until the control box is reset, either by an

internal or external reset (see also subject

“3. Lock out and reset“).

Interrupting the supply line (by models with non volatile lock

out) may not reset a lock out. Therefore, by applying power,

the fan motor switches on for 2-3 secs. before the control

box goes to lock out again in cause of the last lock out.

Error

Possible fault

Burner not working

- Thermostat circuit open

- Faulty electrical wiring

- Mains voltage < 193 V

Fan motor starts for a short - Control box has not been reset

period of time, control box

- Air proving switch not in open

goes to lock out

position

Control box locks out or

- Air proving switch has not closed

recycled during pre-purge

within 60 sec.

- Air proving switch has re-opened

Control box locks out or

- Air proving switch open

recycled at the end

- Flame signal (stray light)

of pre-purge

Burner starts,

- No ignition or no gas

flame not established,

after safety time

lock out or recycling

Burner starts,

- No or to low flame signal (flame

flame established,

does not stick, bad insulation of

after safety time

the ionisation probe, bad connec-

lock out or recycling

tion to frame ground)

- Insufficient light on IRD or UVD

- Sensitivity adjustment

to low on IRD