SV9510/SV9520 SMARTVALVE™ SYSTEM CONTROLS

69-2014

10

LP, at the tank. Also shut off gas supply before

disconnecting manometer and replacing plug. Repeat

Gas Leak Test at plug with main burner operating.

NOTE: Check the inlet pressure before adjusting the

pressure regulator.

1.

Check the full rate manifold pressure listed on the

appliance nameplate. Ignition system control full

rate outlet pressure should match this rating.

2.

With main burner operating, check the ignition

system control flow rate using the meter clocking

method or check pressure using a manometer

connected to the outlet pressure tap on the ignition

system control. See Fig. 4.

3.

If necessary, adjust the pressure regulator to match

the appliance rating. See Tables 7 and 8 for factory-

set nominal outlet pressure and adjustment range.

a. Remove the pressure regulator adjustment cap

screw.

b. Using a screwdriver, turn the inner adjustment

screw clockwise

to increase or

counterclockwise

to decrease the gas

pressure to the burner.

c. Always replace the cap screw and tighten firmly

to prevent gas leakage.

4.

If the desired outlet pressure or flow rate cannot be

achieved by adjusting the ignition system control,

check the ignition system control inlet pressure

using a manometer at the ignition system control

inlet pressure tap. If the inlet pressure is in the

nominal range (see Tables 8A and 8B), replace the

ignition system control. Otherwise, take the

necessary steps to provide proper gas pressure to

the control.

NOTE: If the burner firing rate is above the capacity (at 1

in. wc pressure drop) of the control (see Table 3

for capacities), it may not be possible to deliver

the desired outlet pressure. This is an application

issue, not a control failure. Take whatever steps

are required to correct the situation.

5.

STEP-OPENING PRESSURE REGULATORS

ONLY. Carefully check the burner lightoff at step

pressure. Make sure the burner lights smoothly and

without flashback to the orifice. Make sure all ports

remain lit. Cycle the burner several times, allowing

at least 60 seconds between cycles for the

regulator to resume the step function. Repeat after

allowing the burner to cool. Readjust the full rate

outlet pressure, if necessary, to improve lightoff

characteristics.

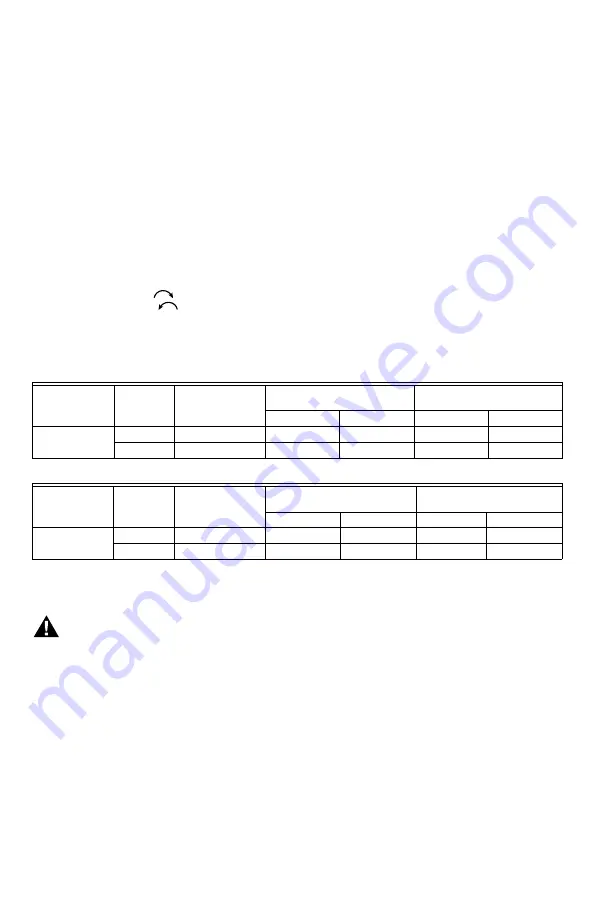

Table 7. Pressure Regulator Specification Pressures (in. wc).

Table 8. Pressure Regulator Specification Pressures (kPa).

MAINTENANCE

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to take the control apart or clean it.

Improper cleaning or reassembly can cause gas

leakage.

Regular preventive maintenance is important in

applications such as in the commercial cooking and

agricultural and industrial industries that place a heavy

load on system controls because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000 to 200,000

cycles per year. Such heavy cycling can wear out the

gas control in one to two years.

• Exposure to water, dirt, chemicals and heat can

damage the gas control and shut down the control

system.

The maintenance program should include regular

checkout of the control as outlined in the Startup and

Checkout section, and the control system as described in

the appliance manufacturer literature.

Maintenance frequency must be determined individually

for each application. Some considerations are:

• Cycling frequency. Appliances that may cycle 200,000

times annually should be checked monthly.

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

• Consequence of unexpected shutdown. Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

• Dusty, wet, or corrosive environment. Since these

environments can cause the gas control to deteriorate

more rapidly, the system should be checked more often.

The system should be replaced if:

• It does not perform properly on checkout or

troubleshooting.

• The gas control is likely to have operated for more than

200,000 cycles.

• The control is wet or looks as if it has been wet.

Model Type

Type of

Gas

Nominal Inlet

Pressure Range

Factory Set Nominal Outlet

Pressure

Setting Range

Step

Full Rate

Step

Full Rate

Standard, Slow

NAT

5.0-7.0

—

3.5

—

3.0-5.0

LP

12.0-14.0

—

10.0

—

8.0-12.0

Model Type

Type of

Gas

Nominal Inlet

Pressure Range

Factory Set Nominal Outlet

Pressure

Setting Range

Step

Full Rate

Step

Full Rate

Standard, Slow

NAT

1.2-1.7

—

0.9

—

0.7-1.2

LP

2.9-3.9

—

2.5

—

2.0-3.0