SV9510/SV9520 SMARTVALVE™ SYSTEM CONTROLS

9

69-2014

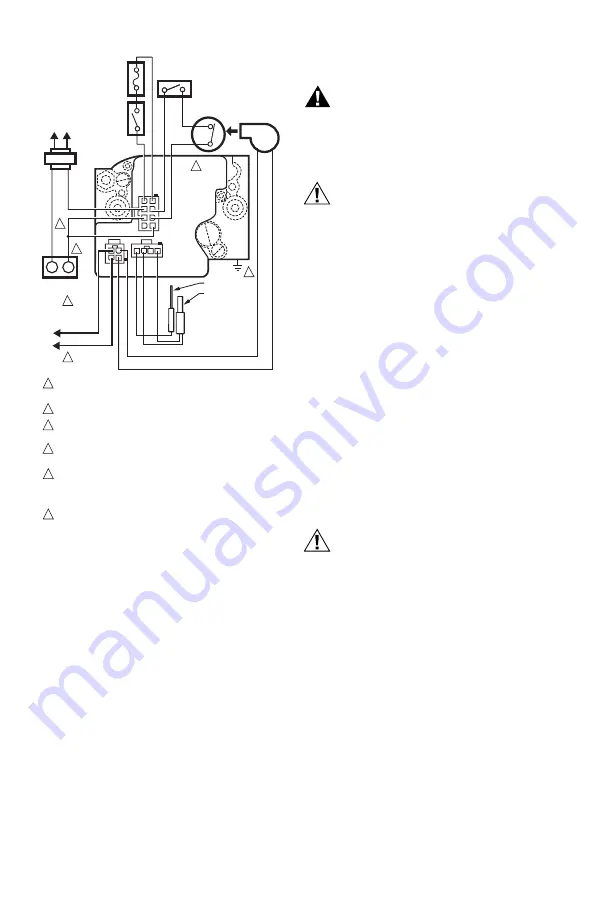

Fig. 10. SV9510/SV9520 typical wiring connections

direct to the system thermostat.

STARTUP AND CHECKOUT

Ignition System Control Switch Settings

Ignition system control switch settings are as follows:

OFF prevents main gas flow through the ignition

system control.

ON permits gas to flow through the control body. At the

appropriate time in the appliance operation, main gas

can flow to the main burner.

NOTE: Controls are shipped with the ignition system

control switch in the ON position. If the appliance

is operated with the ignition system control

switch in the OFF position, the system will

respond as if the air proving switch is stuck in the

no airflow position.

Turn on Main Burner

Follow the instructions provided by the appliance

manufacturer or turn up the thermostat to call for heat.

Perform Gas Leak Test

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury or

death.

Check for gas leaks with soap and water solution

any time work is done on a gas system.

CAUTION

Equipment Damage Hazard.

Liquid can damage the SmartValve™ Control.

Do not spray soap and water solution on the

SmartValve™ housing. Do not use an excessive

amount of soap and water solution to perform the

gas leak test. These can damage the control.

Gas Leak Test

1.

Paint pipe connections upstream of the ignition sys-

tem control with rich soap and water solution. Bub-

bles indicate a gas leak.

2.

If a leak is detected, tighten the pipe connections.

3.

Stand clear of the main burner while lighting to

prevent injury caused from hidden leaks that could

cause flashback in the appliance vestibule. Light

the main burner.

4.

With the main burner in operation, paint the pipe

joints (including adapters) and the control inlet and

outlet with rich soap and water solution.

5.

If another leak is detected, tighten the adapter

screws, joints, and pipe connections.

6.

Replace the part if a leak cannot be stopped.

Check and Adjust Gas Input and Burner

Ignition

CAUTION

Equipment Damage Hazard.

Exceeding input ratings can damage the

controls.

Do not exceed input rating stamped on appliance

nameplate, or manufacturer’s recommended

burner orifice pressure for size orifice(s) used.

Make certain primary air supply to main burner is

properly adjusted for complete combustion. Follow

instructions of appliance manufacturer.

Checking Gas Input by Clocking Gas Meter:

Make certain there is no gas flow through the meter other

than to the appliance being checked. Other appliances

must remain off with the pilots extinguished (or that

consumption must be deducted from the meter reading).

Convert flow rate to Btuh as described in form 70-2602,

Gas Controls Handbook, and compare to Btuh input

rating on appliance nameplate.

Checking Gas Input with Manometer:

Make sure the ignition system control is in the OFF

position before removing outlet pressure tap plug to

connect manometer (pressure gauge). Also move the

ignition system control switch to the OFF position when

removing the gauge and replacing the plug. Before

removing inlet pressure tap plug, shut off gas supply at

the manual valve in the gas piping to the appliance or, for

C1

C2

C3

LOAD

COMMON

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

CONNECT 120V (HOT) LEAD AS SHOWN.

APPLIANCE CHASSIS MUST HAVE RELIABLE CONNECTION TO

EARTH GROUND.

DATA AND R LINES MUST BE CONNECTED TO W ON THERMOSTAT

FOR PROPER SYSTEM OPERATION.

THERMOSTAT MUST HAVE ZERO OFF-STATE CURRENT DRAW.

MECHANICAL SWITCH THERMOSTATS RECOMMENDED. TRIAC

SWITCH THERMOSTATS OR POWER-STEALING THERMOSTATS

ARE NOT RECOMMENDED.

IN THIS APPLICATION, POSTPURGE FUNCTION IS NOT AVAILABLE

AND THE LED FUNCTIONS ONLY DURING A CALL FOR HEAT.

1

4

5

6

6

3

2

2

5

4

1

M12173E

AIR

PROVING

SWITCH

NEUTRAL

HOT

L2

L1

(HOT)

TO

120 VAC, 60 HZ

POWER SUPPLY

ROLL-OUT

SWITCH

LIMIT

SWITCH

COMBUSTION

AIR BLOWER

R

W

R

C

AIR

DATA

40 VA

TRANSFORMER

L1 L2

SV9410/SV9420;

SV9510/SV9520;

SV9610/SV9620

HOT

SURFACE

IGNITER

FLAME ROD

3

AUXILIARY

LIMIT SWITCH

(OPTIONAL)

1

1

2

5

6

7

8

1

2

2

3

3

3

4

4

4