70

Parameter Descriptions

Honeywell

10

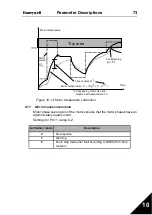

10.8 MOTOR THERMAL PROTECTION (PARAMETERS 9.7 - 9.10)

The motor thermal protection is to protect the motor from overheating. The Honey-

well drive is capable of supplying higher than nominal current to the motor. If the load

requires this high current there is a risk that the motor will be thermally overloaded.

This is the case especially at low frequencies. At low frequencies the cooling effect

of the motor is reduced as well as its capacity. If the motor is equipped with an exter-

nal fan the load reduction at low speeds is small.

The motor thermal protection is based on a calculated model and it uses the output

current of the drive to determine the load on the motor.

The motor thermal protection can be adjusted with parameters. The thermal current

I

T

specifies the load current above which the motor is overloaded. This current limit

is a function of the output frequency.

CAUTION! The calculated model does not protect

the motor if the airflow to the motor is reduced by

blocked air intake grill

NOTE! To comply with UL 508C requirements Motor

over-temperature sensing is required at installation

if the parameter is set to 0.

9.4

S

TALL

PROTECTION

0

= No response

1

= Alarm

2

= Fault, stop according to P2.3

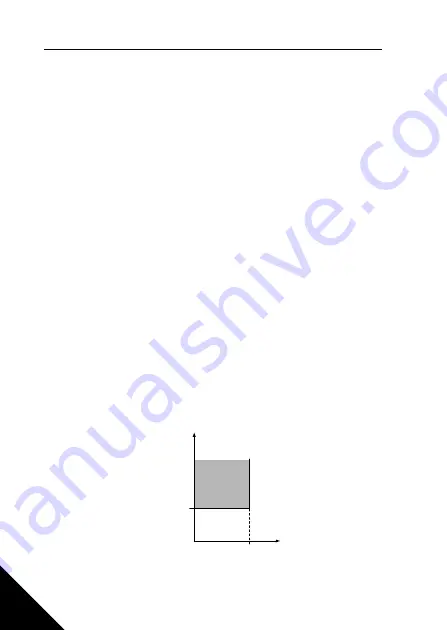

The motor stall protection protects the motor from short time overload situa-

tions such as one caused by a stalled shaft. The stall current is I

nMotor

*1.3, stall

time 15 seconds and stall frequency limit 25Hz . If the current is higher than

the limit and output frequency is lower than the limit, the stall state is true and

the drive reacts according to this parameter. There is actually no real indica-

tion of the shaft rotation.

Figure 10.11: Stall characteristics

f

I

Inmotor *1.3

25Hz

Stall area