SPYDER® LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS

63-2685—03

8

The application engineer must review the control job

requirements. This includes the sequences of operation for the

controller, and for the system as a whole. Usually, there are

variables that must be passed between the controller and other

Spyder Lon controller(s) that are required for optimum system-

wide operation. Typical examples are the TOD, Occ/Unocc

signal, the outdoor air temperature, the demand limit control

signal, and the smoke control mode signal.

It is important to understand these interrelationships early in

the job engineering process, to ensure proper implementation

when configuring the controllers. Refer to the controller

Application Guides.

Power Budget

A power budget must be calculated for each device to

determine the required transformer size for proper operation. A

power budget is simply the summing of the maximum power

draw ratings (in VA) of all the devices to be controlled. This

includes the controller itself and any devices powered from the

controller, such as equipment actuators (ML6161 or other

motors) and various contactors and transducers.

IMPORTANT

• If a controller is used on Heating and Cooling Equip-

ment (UL 1995, U.S. only) and transformer primary

power is more than 150 volts, connect the transformer

secondary common to earth ground (see Fig. 12 on

• When multiple controllers operate from a single

transformer, connect the same side of the transformer

secondary to the same power input terminal in each

device. The earth ground terminal (terminal 3) must

be connected to a verified earth ground for each

controller in the group (see Fig. 13 on page 11).

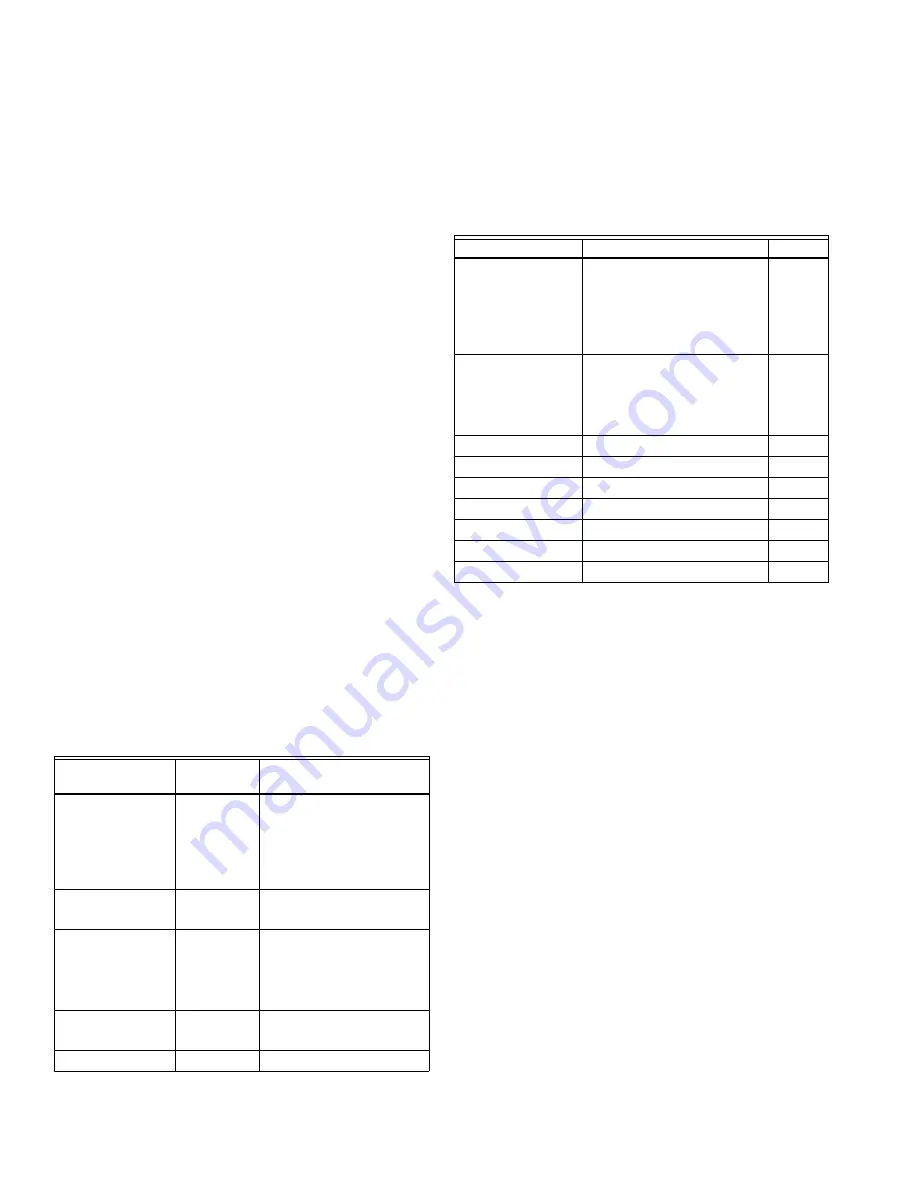

POWER BUDGET CALCULATION EXAMPLE

Table 3 is an example of a power budget calculation for typical

PVL0000AS, PVL4022AS, and PVL6436AS controllers. While

the example is shown for only these models, the process is

applicable for all controller models.

Table 3. Power budget calculation example.

The system example above requires 30.7 VA of peak power.

Therefore, a 100 VA AT92A transformer could be used to

power one controller of this type. Because the total peak power

is less than 33 VA, this same transformer could be used to

power three of these controllers and meet NEC Class 2

restrictions (no greater than 100 VA).

See Fig. 11–Fig. 13 beginning on page 10 for illustrations of

controller power wiring. See Table 4 for VA ratings of various

devices.

Table 4. VA ratings for transformer sizing.

For contactors and similar devices, the in-rush power ratings

should be used as the worst case values when performing

power budget calculations. Also, the application engineer must

consider the possible combinations of simultaneously

energized outputs and calculate the VA ratings accordingly.

The worst case, which uses the largest possible VA load,

should be determined when sizing the transformer.

Each controller requires 24 Vac power from an energy-limited

Class II power source. To conform to Class II restrictions (U.S.

only), transformers must not be larger than 100 VA. A single

transformer can power more than one controller.

GUIDELINES FOR POWER WIRING ARE AS FOLLOWS:

— For multiple controllers operating from a single

transformer, the same side of the transformer

secondary must be connected to the same power input

terminal in each device. The earth ground terminal

must be connected to a verified earth ground for each

controller in the group (see Fig. 13 on page 11).

Controller configurations are not necessarily limited to

three devices, but the total power draw, including

accessories, cannot exceed 100 VA when powered by

the same transformer (U.S. only).

— See Fig. 12 on page 10 for controller power wiring used

in UL 1995 equipment (U.S. only).

— Many controllers require all loads to be powered by the

same transformer that powers the controller.

— Keep the earth ground connection wire run as short as

possible (refer to Fig. 11–Fig. 13 beginning on

— Do not connect earth ground to the controller’s digital

or analog ground terminals (refer to Fig. 11 and Fig.

Device

VA

Information

Obtained From

PVL0000AS,

PVL4022AS, and

PVL6436AS

controllers (include

Series 60 Floating

Damper Actuator)

9.0

R8242A Contactor

fan rating

21.0

TRADELINE

®

Catalog

inrush rating

D/X Stages

0.0

For example, assume

cooling stage outputs are

wired into a compressor

control circuit and have no

impact on the budget.

M6410A Steam

Heating Coil Valve

0.7

TRADELINE

®

Catalog,

0.32A 24 Vac

TOTAL

30.7

Device

Description

VA

PVL0000AS,

PVL4022AS, and

PVL6436AS

controllers and

Series 60 Floating

Damper Actuator

Controller and Actuator

9.0

PUL1012S,

PUL4024S,

PUL6438S,

PVL4024NS, or

PVL6438NS

Controller

5.0

ML684

Versadrive Valve Actuator

12.0

ML6161

Damper Actuator, 35 lb-in.

2.2

ML6185

Damper Actuator SR 50 lb-in

12.0

ML6464

Damper Actuator, 66 lb-in.

3.0

ML6474

Damper Actuator, 132 lb-in.

3.0

R6410A

Valve Actuator

0.7

R8242A

Contactor

21.0