SPYDER® LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS

5

63-2685—03

Before mounting the actuator onto the VAV box damper shaft,

determine the following:

1.

Determine the damper shaft diameter. It must be

between 3/8 in. and 1/2 in. (10 to 13 mm).

2.

Determine the length of the damper shaft. If the length of

the VAV box damper shaft is less than 1-9/16 in.

(40 mm), the actuator cannot be used.

3.

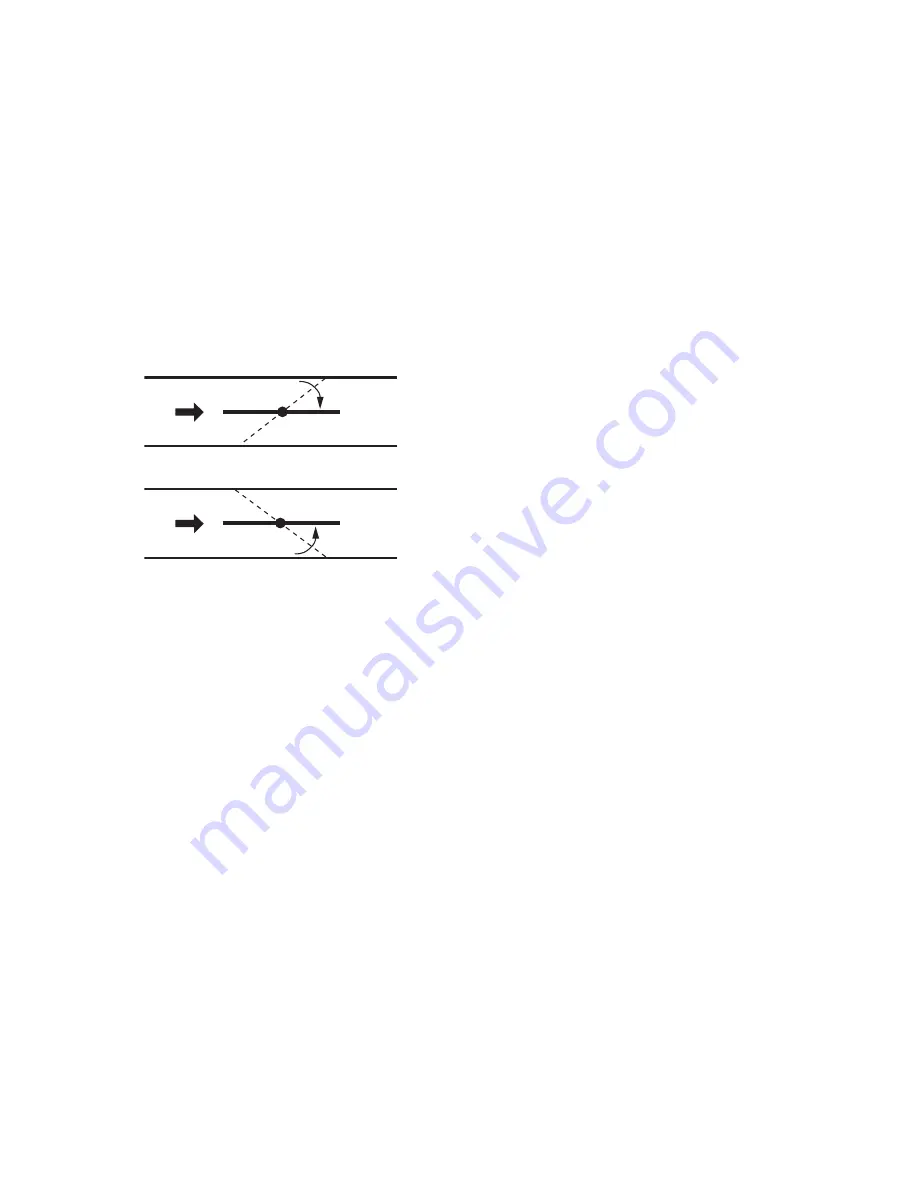

Determine the direction the damper shaft rotates to open

the damper (CW or CCW) (see Fig. 3). Typically, there is

an etched line on the end of the damper shaft that indi-

cates the position of the damper. In Fig. 2, the indicator

shows the damper open in a CW direction.

4.

Determine the damper’s full opening angle (45, 60, or 90

degrees). In Fig. 2, the damper is open to its full open

position of 90 degrees.

Fig. 3. Determining the rotation direction (CW or CCW)

for damper opening.

Mounting Actuator Onto Damper Shaft

(PVL0000AS, PVL4022AS, and PVL6436AS )

The unit is shipped with the actuator set to rotate open in the

clockwise (CW) direction to a full 95 degrees. The extra 5

degrees ensures a full opening range for a 90 degree damper.

The installation procedure varies depending on the damper

opening direction and angle:

1.

If the damper rotates clockwise (CW) to open, and the

angle of the damper open-to-closed is 90 degrees:

a. Manually open the damper fully (rotate clockwise).

b. Using the Declutch button, rotate the universal shaft

adapter fully clockwise.

c. Mount the actuator to the VAV damper box and shaft.

d. Tighten the two bolts on the centering clamp

(8 mm wrench; 70.8–88.5 lb-in. [8–10 Nm] torque).

When the actuator closes, the damper rotates CCW

90 degrees to fully close.

2.

If the damper rotates clockwise (CW) to open, and the

angle of the damper open-to-closed is 45 or 60 degrees:

a. Manually open the damper fully (rotate clockwise).

b. The actuator is shipped with the mechanical

end-limits set at 95 degrees. Adjust the two

mechanical end-limit set screws to provide the

desired amount of rotation. Adjust the two set screws

closer together to reduce the rotation travel.

c. Tighten the two mechanical end-limit screws (Phillips

#2 screwdriver; (26.5–31 lb-in. [3.0–3.5 Nm] torque).

d. Using the Declutch button, rotate the universal shaft

adapter fully clockwise.

e. Mount the actuator to the VAV damper box and shaft.

f. Tighten the two bolts on the centering clamp

(8 mm wrench; 70.8–88.5 lb-in. [8–10 Nm] torque).

g. When the actuator closes, the damper rotates CCW

either 45 or 60 degrees to fully close.

3.

If the damper rotates counterclockwise (CCW) to open, and

the angle of the damper open-to-closed is 90 degrees:

a. Manually open the damper fully (rotate counterclock-

wise).

b. Using the Declutch button, rotate the universal shaft

adapter fully counterclockwise.

c. Mount the actuator to the damper box and shaft.

d. Tighten the two bolts on the centering clamp (8 mm

wrench; 70.8–88.5 lb-in. [8–10 Nm] torque). When

the actuator closes, the damper rotates CW

90 degrees to fully close.

4.

If the damper rotates counterclockwise to open, and the

angle of the damper open-to-closed is 45 or 60 degrees:

a. Manually open the damper fully (rotate counterclock-

wise).

b. The actuator is shipped with the mechanical

end-limits set at 95 degrees. Adjust the two

mechanical end-limit set screws to provide the

desired amount of rotation. Adjust the two set screws

closer together to reduce the rotation travel.

c. Tighten the two mechanical end-limit screws

(Phillips #2 screwdriver; (26.5–31 lb-in. [3.0–3.5 Nm]

torque).

d. Using the Declutch button, rotate the universal shaft

adapter fully counterclockwise.

e. Mount the actuator to the VAV damper box and shaft.

f. Tighten the two bolts on the centering clamp

(8 mm wrench; 70.8–88.5 lb-in. [8–10 Nm] torque).

g. When the actuator closes, the damper rotates CW

either 45 or 60 degrees to fully close.

IMPORTANT

Special precautions must be taken for dampers that

open in a CCW direction. The actuator is shipped with

its rotation direction set to CW to Open, which applies

to the damper direction in steps 1 and 2 above. If the

damper shaft rotates in the CCW direction to open,

the controller software must be programmed to

change the rotation to “Reverse to Open,” which

applies to the damper direction in steps 3 and 4

above.

IMPORTANT

It is advisable to leave the dampers in an open

position after installation to avoid the possibility of

over-pressurizing the duct work on fan startup. Use

the Declutch button (see Fig. 1 on page 4) to open the

box damper on controllers that are powered down, to

prevent over-pressurization in the duct work on fan

startup. To Declutch, press and hold the button to

disengage the motor. Turn the damper shaft until the

damper is open and release the button. When power

is restored to the controller, the controller

synchronizes the damper actuator, so that the

damper is in the correct position upon startup.

Mount Controller

NOTE: The controller may be wired before mounting to a

panel or DIN rail.

Terminal blocks are used to make all wiring connections to the

controller. Attach all wiring to the appropriate terminal blocks

See Fig. 4–Fig. 7 for panel mounting dimensions. See Fig. 8

on page 7 for DIN rail mounting.

AIR

FLOW

AIR

FLOW

CW TO OPEN, CCW TO CLOSE

CCW TO OPEN, CW TO CLOSE

M2067B

TYPE A DAMPER

TYPE B DAMPER