7

107022-14 EN FR26 GLO 0100 Printed in Germany

OSHA 29 CFR 1910.217 states that, “the control system shall be constructed so that a failure within the system does not

prevent the normal stopping action from being applied to the press when required, but does prevent initiation of a

successive stroke until the failure is corrected. The failure shall be detectable by a simple test, or indicated by the control

system.”

Honeywell has developed a self-checking technique that combines reliability with safety. The FF-LS Series safety light

curtain functions with dual channel redundancy and positive self-check monitoring. This means that a faulty component in

the miniature safety light curtain will cause it to fail in a safe mode.

This design meets the highest safety requirements (Type 4 Electrosensitive Protective equipment) described in the

EN61496 European standard. Type 4 safety light curtains are designed and manufactured in such a way that a single

breakdown or an accumulation of failures does not lead to the loss of the safety function when a dangerous situation arises.

The safety function is maintained on a permanent basis.

1.6

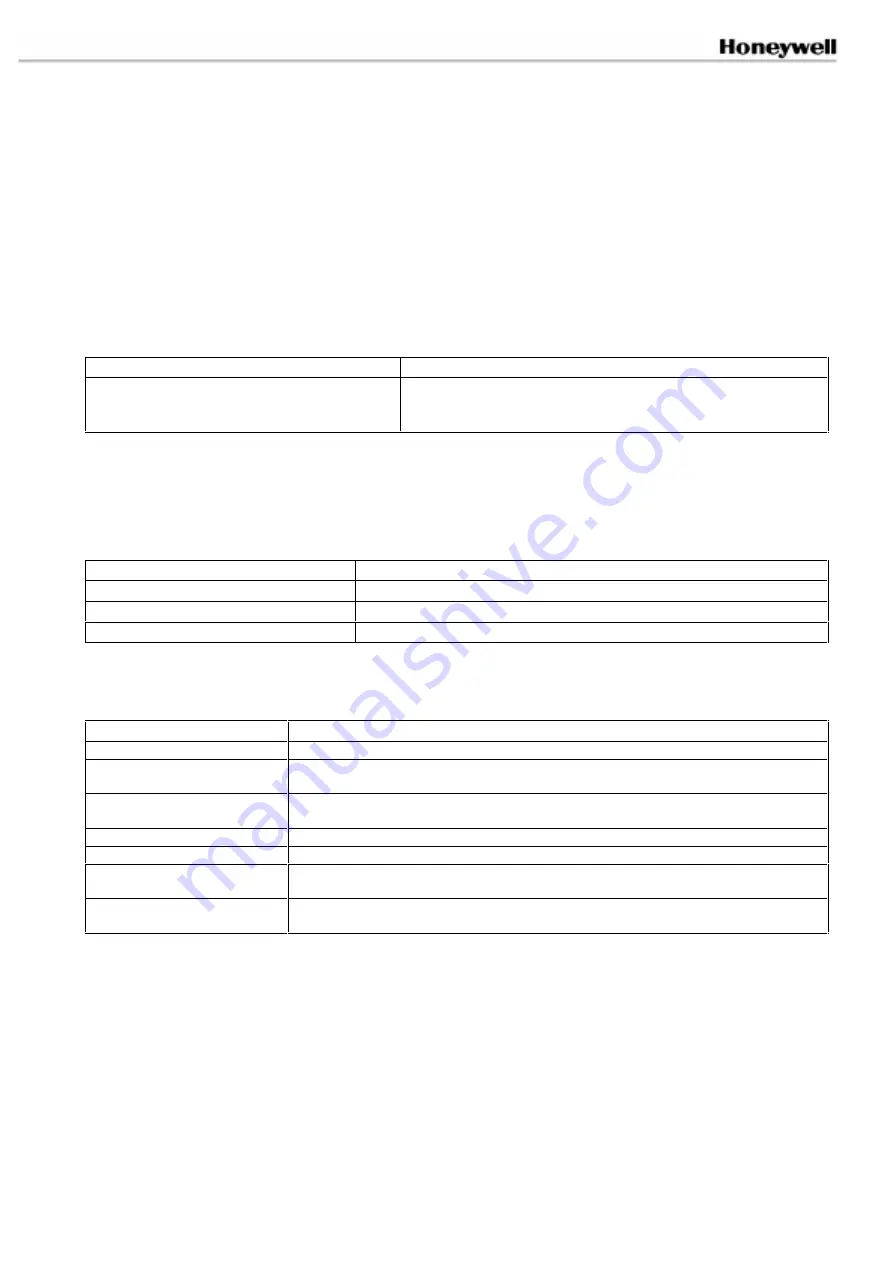

Product Approval

Approvals

Description

TÜV CE Type 4

cCSAus

Only the packaging and the documentation of FF-LS Series

products carry the CE mark; the CE declaration of conformity is

located at the back of this installation manual

1.7

Compliance

1.7.1 European Directives Compliance

The EC type examination certificate granted by the TÜV Hannover/Sachsen-Anhalt ensures conformity of the product with

respect to the essential requirements of the following EEC Directives:

Directives

Number

Machine Directive

89/392 EEC and its amendments: 91/368/EEC, 93/44/EEC and 93/68/

Low Voltage Directive

73/93 EEC

Electromagnetic Compatibility Directive

89/336 CEE

1.7.2 European Regulations Compliance

The installation of a FF-LS Series safety light curtain is subject to strict rules that may vary from country to country.Correct

installation is essential to ensure safe operation and must be carried out according to the appropriate regulations.

Regulation

Title

EN 292

Safety of Machinery - Basic concepts, general principles for design

EN 294

Safety of Machinery - Safety distances to prevent danger zones being reached by the

upper limbs

EN 61496-1/2

(replaces EN 50100-1/2)

Safety of Machinery - Electrosensitive Protective Equipment

EN 60204

Safety of Machinery - Electrical equipment of machines

EN 954

Safety of Machinery - Safety related parts of control systems

pr EN 999

Safety of Machinery - The positioning of protective equipment in respect of approach

speeds of parts of the human body

pr EN 811

Safety of Machinery - Safety distances to prevent danger zones from being reached by

the lower limbs

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...