107006-11 EN FR26 GLO 0300 Printed in Germany

14

3. Description and Operation

3.1 Overview

This chapter contains terms and concepts related to safety and the application of the FF-SE. The importance of

the installer’s role in the set-up and installation of the machine guarding systems is discussed. This section also

contains specification and order guide information.

3.2 General

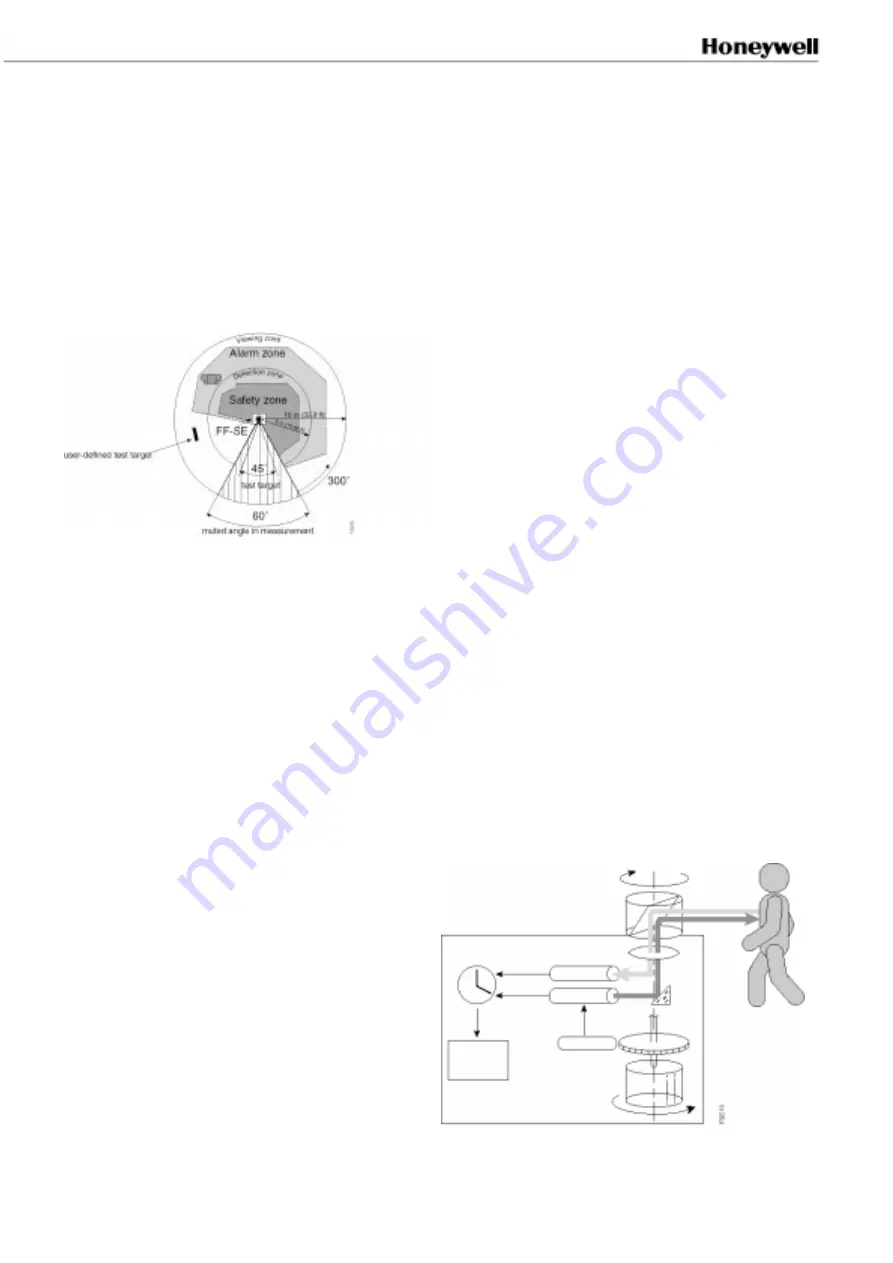

The FF-SE is an ElectroSensitive Protective Equipment compliant with category 3 of EN 954-1. It monitors user

defined dangerous zones. As soon as an object or a person penetrates the monitored area, the following events

take place:

•

When an object is present in the alarm zone, the

FF-SE causes the switching of a signalling

(alarm) contact. This contact can be connected

to an acoustic or optical warning device. It

indicates to clear the zone in order to prevent a

shut-down.

•

When an object is present in the safety zone, the

FF-SE causes the switching of two safety

contacts. These contacts trigger an immediate

shut-down of the monitored machine.

The programming software allowing the definition of

the protection areas is sold separately.

Figure 3-1 : Protection zones

3.3 Principle of operation

The type of laser beam used in this sensor is invisible and corresponds to IEC 825 class 1, representing no

hazard to the eyes. The measuring range begins directly in front of the lens.

The fixed test target is to ensure that the beam status is correct, through reflectivity and position check. This

also checks the lens contamination.

❚

Measuring principle

The FF-SE emits a pulsed laser beam (Class 1 infrared laser) rotating in a 360° circle. This circle is obtained

thanks to the reflection of this beam on a revolving mirror. This pulsed laser beam is diffusely reflected by the

surrounding objects, and the returning signal is received by the photo diode. The distance of the object is

determined by measuring the time the laser pulse takes to return to the FF-SE. This measuring principle is

similar to that used in RADAR systems.

At each rotation, the FF-SE carries out 600

measurements on 300° (60° are required for the

measurement of the fixed test target). The position of

each beam is determined by an angle encoder.

The position of an object and measuring data can be

determined by connecting a computer to the output

interface.

Figure 3-2 : Measuring principle

Motor

Angle encoder

Evaluation of

the distance

starts

stops

Stop watch

Laser transmitter

Laser receiver

Laser lens

Laser beam

Laser echo

Revolving deflector

mirror

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...