For application help: see Warranty Information

Honeywell

•

PK 107007-01 EN FR26 GLO 0298 Printed in France 31

Connections and Setup

Overview

IMPROPER ELECTRICAL INSTALLATION

•

Each safety mat activation must stop dangerous machine operation within the response

time of the components.

•

Clearing the sensing zone must not start dangerous machine operation. When restarting

machine operation, a normal machine control start sequence must be used.

•

If electrical power is removed from a machine, its restoration must not initiate dangerous

machine operation; a normal machine control start sequence must be used.

•

If a safety mat system is activated, the machine must NOT be able to restart.

•

The external safety relays located between the safety outputs and the machine control

circuitry must be monitored.

•

In the event of component failure, the machine control circuitry must stop dangerous

machine operation and prevent the next machine cycle activation.

•

A Programmable Logic Controller must NOT be able to override a manual restart function.

•

Strictly adhere to all electrical connection instructions and local wiring standards.

•

If the module is in the automatic operation mode, another part of the safety control circuitry

must keep the latched function engaged.

•

To keep the latched function engaged and maintain control reliability, use safety

components only. Do not use a programmable logic controller (PLC).

Failure to comply with these instructions could result in death or serious injury.

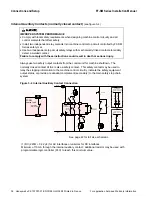

This section contains information about fiber optic and electrical connections, interfacing and

the setup of the control unit and safety mat. According to ANSI B11.19 - 1990, the safety mat

shall be interfaced with the machine control system so the mat’s stop signal causes immediate

stopping action of the machine and shall require the reinitiation of the operator’s control prior

to the start or continuation of machine motion. Connection of the safety mat to the machine

control circuitry must be carried out in such a way that the external relaying (safety relays with

positive-guided contacts) used in the interface are systematically self-checked (monitored)

before each machine cycle. Using safety relay technology, Honeywell safety control modules

(FF-SR Series) provide cross monitoring and ensure proper machine control operation.

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...