FF-SRS5939 Series

PK107033-EN

7

107033-12 EN FR26 GLO 0499 Printed in Germany

APPLICATION EXAMPLES

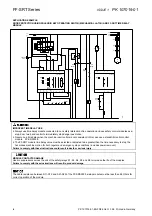

FIG. 12. WIRING DIAGRAM (USING TWO NORMALLY OPEN CONTACTS)

(1) : Always install arc suppressors across the coils of external

safety relays (these arc suppressors are not necessary, if

the FSDs relays K1 & K2 are supplied by the Honeywell

FF-SRE3081 extension module for which correct wiring is

also indicated in this wiring diagram)

(2) : Use a 120/230 Vac electrically insulated push-button

(3) : The module and the ESPE must be connected

to the same 0V

ESPE : Electrosensitive Protective Equipment

FSD : Final switching Device

(A) : Jumpered if the manual restart mode is not

used

(B) : Jumpered if the FSDs K1 and K2 are not used

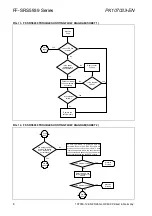

Restart sequence:

The safety control module will restart a 100 ms after removing the stop condition, or after releasing the

START push button. In the manual restart mode, pressing the START push-button for less than 0.1 s or for

more than 1.5 s will not restart the module (permanent short-circuit detection is performed through this

input). The green relay outputs status indicator will turn ON indicating that the internal relays are energized.

The two normally open safety contacts will close and the normally closed contact will open (this contact can

be used for signalling purpose) allowing the machine to operate.

External contactors:

The output contacts switching capacity can be reinforced by using external contactors (K1 and K2) with

positive-guided contacts. The proper operation of the external contactors is monitored by looping the NC

contacts into the FSDs monitoring loop (terminals Y1/Y2). The module will not restart if the FSD monitoring

loop remains permanently open, or remains closed for more than 250 ms after the closing of the module

normally open contacts. In this case, the internal relays will be briefly energized.

CONTACT REINFORCEMENT VIA EXTERNAL RELAYS

•

If contact reinforcement via external safety relays or the FF-SRE3081 Extension module is necessary,

connect one normally closed contact of each relay K1 and K2 in series into the Restart loop (terminals

Y1/Y2).

IMPROPER EXTERNAL SAFETY RELAYS PERFORMANCE

•

Use two independent stop circuit safety relays with mechanically linked contacts (such as GE CR120 BP

Machine Tool Relays or Telemecanique CA3-D relays) to reliably detect a welded contact.

IMPROPER AUTOMATIC START MODE IN PERIMETER GUARDING APPLICATIONS

•

If the module is in the automatic start mode, another part of the safety control circuitry must keep the

latched function engaged.

Failure to comply with these instructions could result in death or serious injury.

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...