4

107035-02 EN FR26 ROW 0499 Printed in Germany

MODE SETTING

ELECTRICAL SHOCK

Remove power from FF-SR Series control modules

and machine during installation and before setup.

Failure to comply with these instructions could

result in death or serious injury.

To set the desired mode of operation, remove the

front panel (see figure 7). Refer to the back of the

front panel for switch setting options (see figure 8).

Set switches as required, then replace front panel.

S1 AND S2 SWITCHES

(Refer to the important warnings on page 6.)

This module contains two internal switches (S1 and

S2) that are used to set various modes of operation.

This feature ensures application flexibility.

Switches S1 and S2 are used to select automatic

start and manual start with or without cross fault

detection.

Switch S1 is used to select an operating mode for

cross fault detection between the two inputs.

Cross fault monitoring must be used when two

independent safety inputs are provided to this

module to increase the overall safety level of the

solution (see typical application examples).

Switch S2 is used to select automatic start or

manual start. Terminals S33 and S34 must be

connected for automatic start to function.

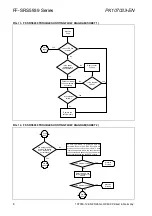

FIG 7. FRONT PANEL REMOVAL

To gain access to the two internal switches, it is not

necessary to remove the terminal blocks. Just unclip

the front panel as shown in figure 7.

FIG 8. INTERNAL SWITCH SETTING

(located behind the front panel)

S1 Cross fault detection

manual

without

automatic

Factory Setting

S2 Start mode

with

ELECTRICAL INSTALLATION

Multiple wiring configurations are possible for the

FF-SRS5925 dual channel emergency stop module.

General guidelines are provided because there are

various ways to interface the module to machine

control circuitry. Refer to the important warnings

(page 6) and the application examples (pages 7

through 9).

SAFETY CONTROL MODULE DAMAGE

Do not supply any current/voltage to the FF-

SRS5925 safety module control inputs. These

inputs receive their voltage (24 Vdc under a 40 mA

current) from external power via pins A1 and A2.

Failure to comply with these instructions will

result in product damage.

LED INDICATORS

The FF-SRS5925 module has three green LED status

indicators (Power, K1 and K2) as illustrated below.

The Power LED indicates power is applied to the safety

control module. Illuminated K1 and/or K2 LED’s

indicate(s) that the corresponding internal safety relay is

energized. Both K1 and K2 relays must be energized

to have the normally open contacts 13/14 and 23/24 in

a closed position. If one of the safety relays de-

energizes, the normally closed contact will close.

Screw driver

Panel

Screw driver

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...