5

107035-02 EN FR26 ROW 0499 Printed in Germany

FUNCTIONAL DESCRIPTION

In the manual start mode, the module accepts input

from the safety device (light curtain, safety mat,

safety switches, etc.) between S11/S12 and

S21/S22 after activation of the push button between

S33 and S34; then, the normally open safety

contacts (13/14, 23/24) will close and the normally

closed contact (31/32) will open.

In the automatic start mode, the module accepts

immediate input from the safety device (light curtain,

mat, safety switches, etc.) between S11/S12 and

S21/S22 (S33 and S34 are jumpered if external

relay monitoring is not needed); then, the normally

open safety contacts (13/14, 23/24) will close and

the normally closed contact (31/32) will open.

In either mode, if the safety device is actuated

(emergency stop condition occurs), the normally

open contact will open immediately and the normally

closed contact will close. This emergency stop

condition is relayed via the safety contacts of the

module to the machine control circuitry to arrest

dangerous motion and/or remove power.

EXTENSION MODULES AND EXTERNAL

CONTACTORS

One or more FF-SRE3081 Extension modules or

external contactors with positively driven contacts

can be used to multiply the number of contacts of the

FF-SRS5925 Emergency Stop Module. If multiple

safety contacts are used in parallel with one load,

the maximum admissible current can be increased.

For connection of the FF-SRE 3081 to the FF-SRS

5925 module, see the Installation Instructions for the

FF-SRE 3081 Extension Module.

CONTACT MULTIPLICATION VIA EXTERNAL

RELAYS

•

If contact multiplication via external safety relays

(or the FF-SRE3081 Extension module) is

necessary, connect one normally closed contact

of each relay (or 81/82) in series into the restart

loop between terminals S33/S34 (Final Switching

Device (FSD) monitoring).

•

Use two independent stop circuit safety relays

with mechanically linked contacts to reliably

detect a welded contact.

Failure to comply with these instructions could

result in death or serious injury.

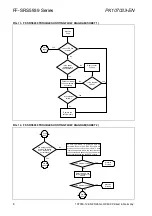

FIG 9. BLOCK DIAGRAM

31

32

FIG 10. MODULE FRONT PANEL

FIG 11. FUNCTIONAL DIAGRAM

Start push-

button

closed

opened

Inputs

Output

Emergency

Stop

closed

opened

K1

K2

* Line fault Detection on Start push-button:

If the start push button is closed before voltage is

applied to S12 and S22 the safety contacts of the

module cannot close.

This additional feature ensures the detection of a line

fault via the start push-button or a blocked start push

button. In case of a push-button failure the module

can not be restarted.

Overvoltage and

short circuit

protection

Monitoring

Logic

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...