T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

31

63-7147—3

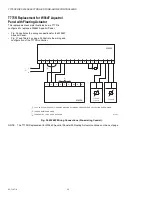

T775M2030 Replacement for W973A Logic

Panel (continued)

In this replacement application, the T775M2030 provides the

following, as described in Table 3:

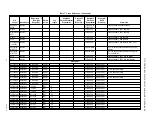

Table 3. T775M2030 Replacement for W973A

Component/Function

W973A Logic Panel

T775M2030 Replacement

Thermostat

T7067

Sensor A (Room) - C7130B1008.

Discharge Sensor

C7046

Sensor B (Discharge) - C7046D1008.

Heating/Cooling Motor

M954

Series 90, 4-20 mA, 0-10 Vdc, or 2-12 Vdc motor may be used.

Fan Start

Fan Start Relay

If a relay is available, it can be used for fan control (e.g., 1 stage Heat and 2

stage Cool using the T775M2030).

Economizer

M955

With the T775M2030 there are two modulating outputs. Therefore, two of the

three functions (Heat, Cool, or Economizer) are available to be used. The

example in Fig. 35 uses the Heat and Cool functions; no Economizer.

Outside Air Changeover

H205

Optional – SPDT Changeover (H705).