THE ROUND® CREATIVE SERIES Y460A2003 THERMOSTAT

3

69-1358

❑

Firmly tighten the screws.

❑

Push the excess wire back into the wall.

❑

Plug the hole with nonflammable insulation to

prevent drafts from affecting the thermostat

operation.

Y460A for heating/cooling system using separate RC-

RH terminals. If old thermostat has single R terminal,

refer to jumper drawing in Subbase Wiring procedure.

6 MOUNT YOUR THERMOSTAT

❑

Set the heat anticipator indicator to 1.2 before

mounting to prevent the anticipator from burning out

during installation.

❑

Align the thermostat over the subbase and tighten

the three captive mounting screws (see Step 4).

These captive mounting screws complete the

electrical connections to the thermostat.

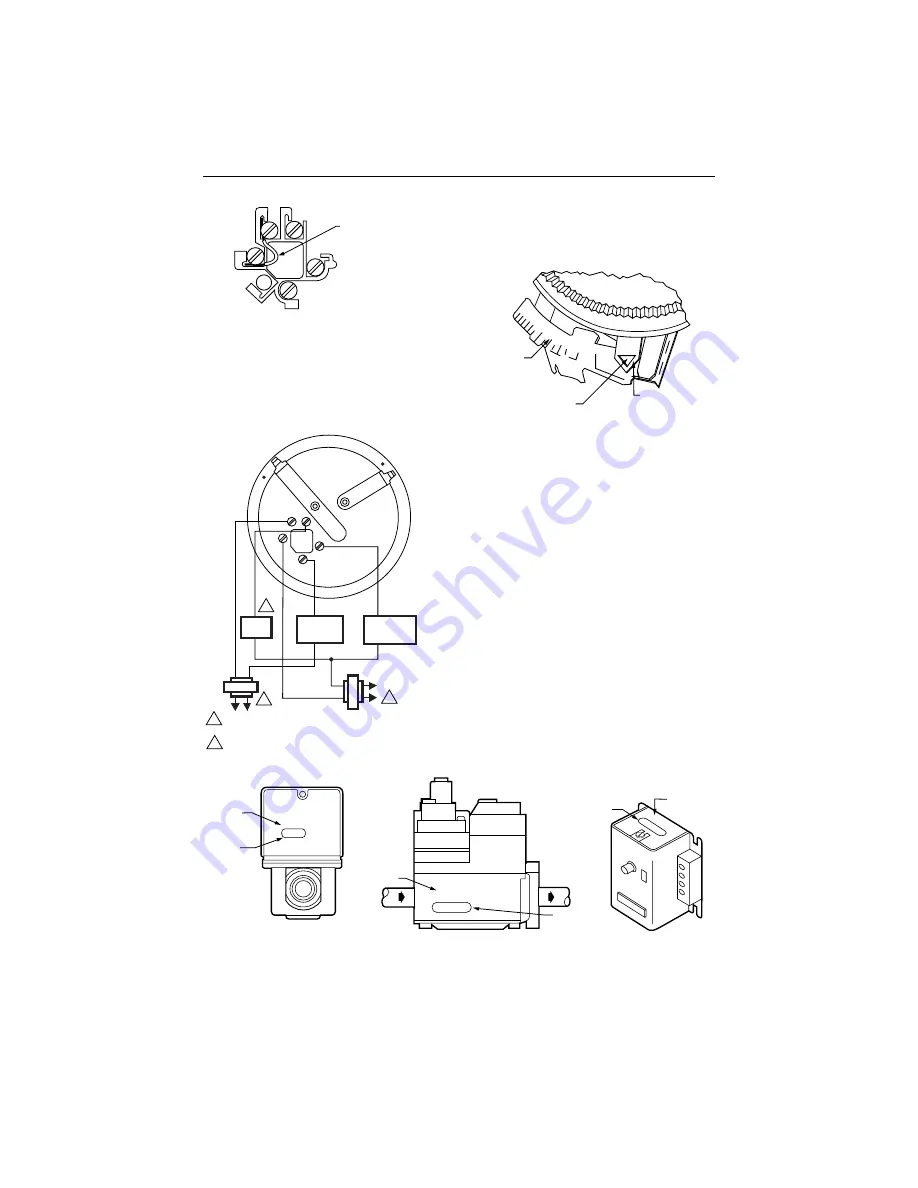

7 SET HEAT ANTICIPATOR

INDICATOR

❑

Be sure the thermostat adjustable heat anticipator is

set correctly to accurately control the temperature.

An incorrect setting (if too high) can result in wide

room temperature swings or (if too low) burn out the

anticipator, which voids the thermostat warranty.

❑

Make sure you have the current draw (anticipator

setting) for your system. This is the number you

wrote in the box in Step 3. If you were unable to find

the current draw for Step 3, this information can be

found printed on the primary control at the furnace or

boiler. The primary control is usually a gas valve, a

relay or burner control box, Aquastat® Controller or

zone valve with the thermostat wires connected to it.

These controls are usually located behind the

furnace cover; see the illustration.

❑

If the current rating is still unavailable:

— Remove the W wire from the subbase.

— Connect one probe of an ac ammeter (0 to 2.0A,

for example) to the W wire and connect the other

probe to the W terminal.

R

G

R

W

Y

EXAMPLE: FOR RC TO RH

JUMPER, STRIP WIRE

END LONG ENOUGH TO

JOIN BOTH TERMINALS.

M1277A

H

C

M13418

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

IN HEATING, THE FAN IS CONTROLLED BY ANOTHER CONTROLLER,

SUCH AS A HONEYWELL L4064 FAN AND LIMIT CONTROLLER OR

FAN TIMER.

1

1

1

COOL

HEAT

O

F

F

FAN

ON

AUTO

G

R

R

H

Y

W

C

HEATING

RELAY OR

VALVE COIL

COOLING

CONTACTOR

COIL

FAN

RELAY

2

LONGER

.15

.12

.2

.6

.8

1.0

.5

.4

.3

HOLE SUITABLE FOR

PENCIL POINT

TO MOVE INDICATOR

HEAT

ANTICIPATOR

INDICATOR

SCALE

M1368

V8043E 1004 4

24V 50/60CY

.32 AMP @ 60CY

8406

24 Vac 50/60 Hz

0.4 AMP

30 VAC

0.2

A

M

P

T

F

T

F

OIL BURNER CONTROL

SHOWS

CURRENT

DRAW

SHOWS

VOLTAGE

RATING

M6116B

FROM MAIN

FUEL SUPPLY

SHOWS

VOLTAGE

RATING

TO

BURNER

SHOWS

ANTICIPATOR

SETTING

TYPICAL GAS VALVE

ZONE VALVE

SHOWS

VOLTAGE

RATING

SHOWS

ANTICIPATOR

SETTING