TZ-4 TOTALZONE® ZONE CONTROL PANEL

68-0259-1

14

Purge Mode

At the end of every call for heat or cool, the panel enters a

Purge mode that holds open the calling zone damper for two

(default) or three and one-half minutes.

During this time, the panel or the HVAC equipment can be

configured to operate the fan. The Purge LED lights to signal

that the system is in the Purge mode. Pressing the purge

override button overrides the Purge mode.

Unless there is a new call for heat or cool during the Purge

mode, all dampers are moved to the Open position at the end

of purge.

The panel can be configured to open all dampers during the

purge mode.

Individual Zone Fan Control

When all zones are satisfied, the fan switch of each

thermostat controls the fan operation for that zone.

— When the fan switch is in the On position, the fan is

energized, and dampers close to zones where fan switch is

in Auto position.

— During a call for heat or cool at this time, the circulation

mode ceases, and the heat or cool call is honored.

— When the zone calling is satisfied, the circulation call

resumes.

Single and Multi-Stage Operation

The panel can control up to three stages of heating and two

stages of cooling:

— First stage is energized by the thermostat.

— Second stage of heating or cooling and third stage of

heating can be energized by the thermostat, timer, or the

percentage of zones calling. (For instance, first and second

stage of heat and cool can be thermostat energized and

third stage heat can be configured for timer energizing.)

— See Tables 5 and 6 for second and third stage

configuration. Note that second and third stage can be

controlled differently. Set stages not used to Off.

DIP Switch bank 4, switches 1-4, are used to configure the

staging method:

— Switches 1 and 2 configure second stage control. See

Table 4.

— Switches 3 and 4 configure third stage control. See Table.

5.

— When stage two or three is not used, disable that stage by

turning off the corresponding switches.

Single Stage

If equipment is single stage, set bank 4, DIP switches 1-4 Off:

THERMOSTAT-CONTROLLED STAGES

Use a thermostat that energizes W2 and Y2 for second stage

of heat and cool, and W3 for third stage of heat. Configure for

thermostat as shown in Tables 4 and 5.

TIMER-CONTROLLED STAGES

— The Timer energizes second stage of heat or cool after the

first stage begins calling for the set amount of time.

— The third stage of heat is energized once the second stage

of heat is calling for the set amount of time.

— Second and third stages remain energized until the call for

heat or cool is satisfied.

See Table 6 for stage timer configuration of DIP switch bank 4,

switches 5, 6, and 7.

PERCENTAGE OF ZONES CALLING—CONTROLLED STAGES

Percentage of zones calling energizes second or third stage

based on the percentage of zones called for heat or cool on

the TZ-4 and TAZ-4.

The percentage of zones necessary to turn stages two and

three on and off:

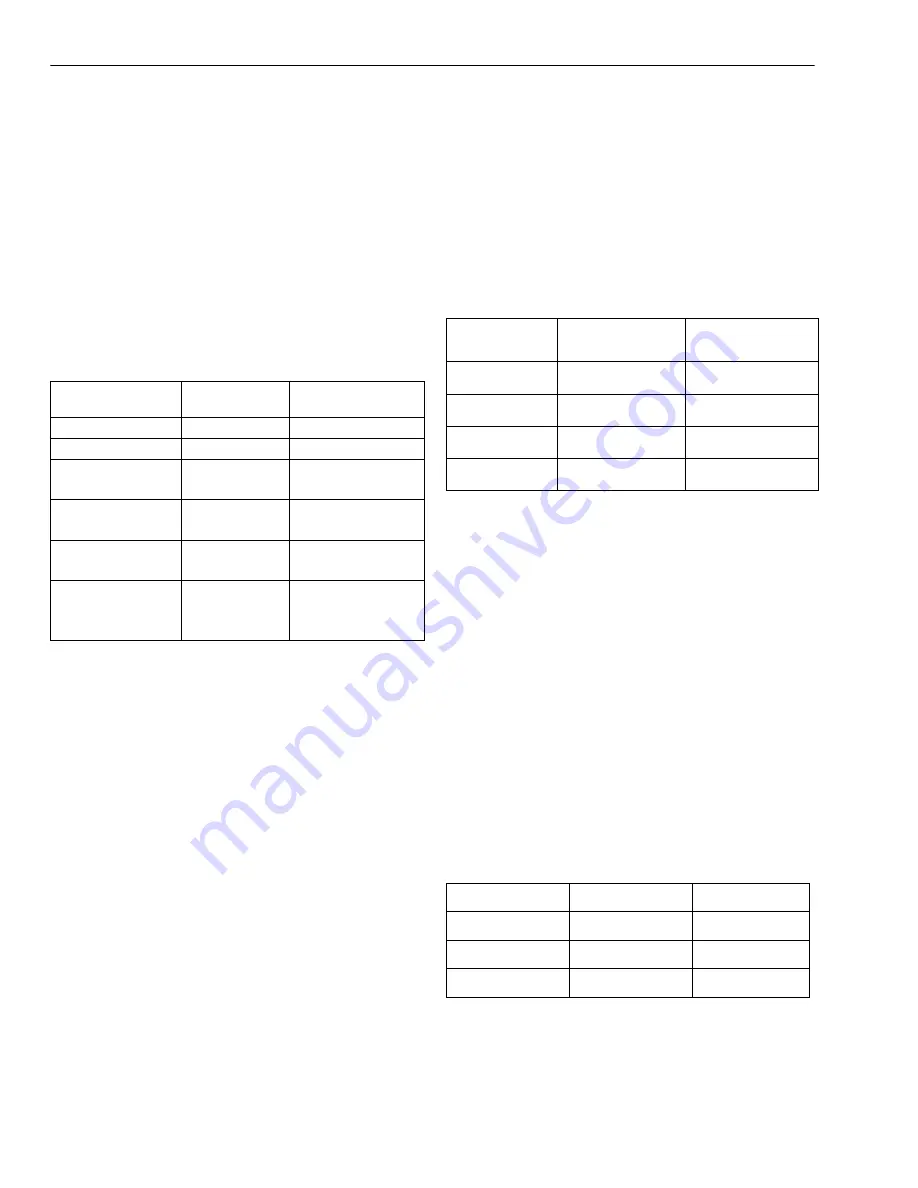

DIP Switch

Number

Status

Purge Operation

5-3

Off

3.5 minutes

5-3

On

2 minutes

5-4

Off

Panel control of fan in

purge

5-4

On

HVAC control of fan

in purge

5-5

Off

All dampers open

during purge

5-5

On

Damper positions

unchanged during

purge

DIP Switch

Number

Stage

Status

4-1

2

nd

Stage

Off

4-2

2

nd

Stage

Off

4-3

3

rd

Stage

Off

4-4

3

rd

Stage

Off

Stage

On

Off

Stage 2 Heat

>33%

</=25%

Stage 2 Cool

>33%

</=25%

Stage 3 Heat

>66%

</=56%