Q314 and Q327A

Pilot Burners

J. H. • Rev. 12-92 • © Honeywell Inc. 1992 • Form Number 69-0519—3

TRADELINE

Application

Pilot burners provide main burner ignition for standing pilot natural and LP gas systems. Used with a thermocouple to provide

automatic pilot safety control. Used with a thermopile in a self-powered system. See Table 1 for model specifications.

TABLE 1—MODEL SPECIFICATIONS.

Primary

Type of

Pilot Tip

Model

Aerated

Orifice

Type

Includes

Q314A

No

Insert

Target

Includes natural and LP gas orifices, 1/4 in.

compression fitting, “F,” “K,” or “L” tip styles,

“B” mounting bracket, and “A” mounting bracket

adapter.

Q327A

Yes

Spud

Target

Includes natural and LP gas orifices, 1/4 in.

compression fitting, and “B” mounting bracket

with screws.

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

instructions can damage product or cause a hazardous condi-

tion.

2. Check ratings given in instructions and on product to

make sure product is suitable for your application.

3. Make sure installer is a trained, experienced service

technician.

4. After completing installation, use these instructions to

check out product operation.

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Follow these warnings exactly.

1. Disconnect power supply before wiring to pre-

vent electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas,

turn off gas supply at appliance service valve

before starting installation and perform Gas

Leak Test after completion of installation.

3. Do not bend pilot tubing at the control or pilot

after compression nut has been tightened. Gas

leakage at the connection may result.

Follow appliance manufacturer’s instructions if avail-

able; otherwise, use instructions provided below.

LOCATION

1. Position pilot burner for easy access, observation, and

lighting. In replacement applications, replace pilot burner

with an identical unit and position new pilot burner in the

same location and orientation as the original pilot burner.

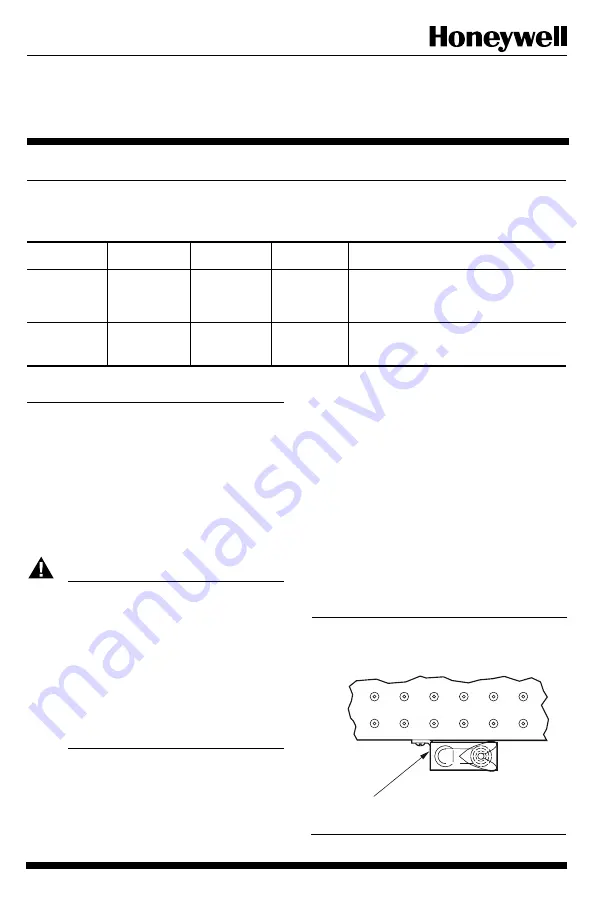

2. Mount pilot burner on main burner. Mounting surfaces

other than the main burner can shift, bend, or warp as furnace

expands and contracts while operating. See Fig. 1.

3. Mount pilot burner so the ignition flame remains

properly positioned with respect to the main burner flame.

See Fig. 2.

4. Supply pilot flame with ample air free of combustion

products.

5. Do not impinge pilot flame on adjacent parts. Do not

impinge main burner flame on pilot burner.

6. Do not expose pilot flame to falling scale which could

impair ignition of main burner.

7. Do not expose pilot burner to main burner rollout while

igniting or extinguishing.

8. Do not expose pilot flame to drafts that push or pull

pilot flame away from the thermocouple or thermopile.

Fig. 1—Mount pilot burner on main burner.

PILOT

BURNER/GENERATOR

MUST BE RIGIDLY

POSITIONED

RELATIVE TO

MAIN BURNER

M1263

Summary of Contents for TRADELINE Q314

Page 6: ...6 ...

Page 7: ...7 69 0519 3 ...