2

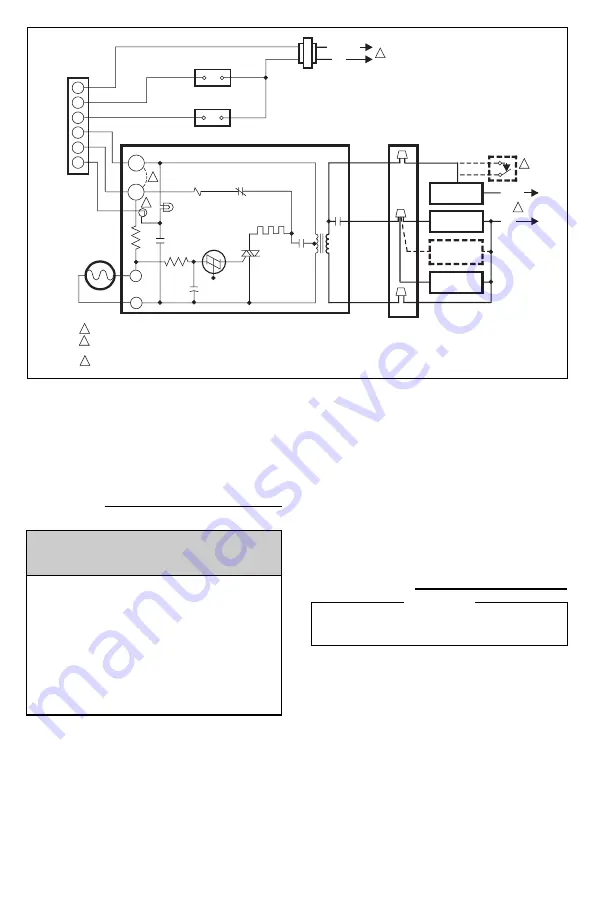

Fig. 3—Typical hookup for Tradeline R8184G with indicator light and isolated alarm relay.

2. Safety switch should lock out in safety switch timing

(see label). Indicator light should come on. Ignition and

motor should stop and oil valve should close.

Simulate power failure:

1. Follow starting procedure to turn on burner.

2. With burner running, trip circuit breaker or remove

fuse to turn off power to the system.

3. Burner should stop.

4. Restore power. Burner should restart.

If system does not operate as described, proceed to

Troubleshooting.

TROUBLESHOOTING AND

MAINTENANCE

IMPORTANT

This control contains no field-serviceable parts. Do

not attempt to take it apart. Replace entire control if

operation is not as described.

PRELIMINARY STEPS

1. Check wiring connections and power supply. Make

sure power is on to the controls, burner motor, and ignition

transformer.

2. Make sure limit control is closed.

CHECK OIL PRIMARY RELAY

NOTE: You’ll need an insulated jumper wire with both ends

stripped.

1. Disconnect cad cell leads from F-F terminals.

2. Reset safety switch and set thermostat to call for heat.

Burner should start.

3. Within safety switch timing, jumper F-F terminals with

insulated jumper wire. Burner should continue to run.

4. After safety switch timing, remove jumper. Burner

should shut down in safety switch timing.

5. If operation is not as described, replace oil primary

control.

Mount control as shown in Fig. 1 or 2. After mounting,

make low voltage connections to the screw terminals. Strip

leads 3/8 in. [10 mm] and insert under terminal screw. See

Fig. 1 or 2. Connect cad cell leads to F-F terminals and

thermostat leads to T-T terminals. See Fig. 3 or 4.

CHECK SAFETY FEATURES

Simulate flame failure:

1. Follow starting procedure to turn on burner.

2. Close hand valve in oil supply line.

3. Safety switch should lock out approximately in safety

switch timing indicated on label. Indicator light should come

on. Ignition and motor should stop and oil valve should

close.

Simulate ignition failure:

1. Follow starting procedure to turn on burner, except do

not open oil supply hand valve.

CHECKOUT

START SYSTEM

WARNING

Fire hazard.

Can cause severe burns.

Make sure combustion chamber is free of oil or oil

vapor before starting system.

1. Push in and release red reset button.

2. Open hand valve in oil supply line.

3. Make sure system is powered. Check circuit

breaker or fuse and close system switch, if

provided.

4. Set thermostat to call for heat.

5. Burner should light and operate until call for

heat ends.

JUNCTION BOX

BLACK

L1

(HOT)

L2

LIMIT

BURNER

MOTOR

IGNITION

OIL VALVE

(OPTIONAL)

ORANGE

WHITE

BILATERAL

SWITCH

CAPACITOR

TRIAC

1K1

R2

R8184G PROTECTORELAY CONTROL

SAFETY

SWITCH

R1

1K2

M718

SAFETY

SWITCH

HEATER

1K

CAD CELL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

F

F

COOLING

CONTROL

2

LINE VOLTAGE

THERMOSTAT

2

1

TO USE R8184 WITH LINE VOLTAGE CONTROLLER, JUMPER T-T TERMINALS AND CONNECT LINE

VOLTAGE THERMOSTAT IN SERIES WITH LIMIT CONTROLLER.

3

T(W)

T(R)

LOCKOUT

INDICATOR

LED

SAFETY

SWITCH

R

G

Y

W

X

C

RH

FAN

RELAY

L1 (HOT)

L2

1

2

3 REMOVE PLUG AND ROUTE VIOLET LEADWIRE THROUGH HOLE IN BASE OF R8184.

T87F/Q539A

COOLING

TRANSFORMER

VIOLET