1

69-0838

a

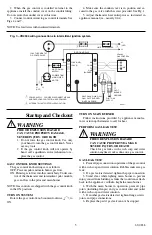

Capacity based on 1000 Btu/feet

3

, 0.64 specific gravity natural gas at 1 inch wc pressure drop [37.3 MJ/meter

3

, 0.64 specific

gravity natural gas at 0.25 kPa pressure drop].

Size

(Inlet x Outlet)

Capacity (at 1 inch

wc pressure drop)

a

Minimum

Regulated Capacity

Maximum

Regulated Capacity

1/2 x 1/2

240 feet

3

/hour

[6.8 meter

3

/hour]

30 feet

3

/hour

[0.8 meter

3

/hour]

340 feet

3

/hour

[9.6 meter

3

/hour]

1/2 x 3/4

270 feet

3

/hour

[7.6 meter

3

/hour]

30 feet

3

/hour

[0.8 meter

3

/hour]

370 feet

3

/hour

[10.5 meter

3

/hour]

3/4 x 3/4

300 feet

3

/hour

[8.5 meter

3

/hour]

30 feet

3

/hour

0.8 meter

3

/hour]

415 feet

3

/hour

[11.8 meter

3s

/hour]

J.D. • 4-94 • ©Honeywell Inc. 1994 • Form Number 69-0838

VR4304

Intermittent Pilot

Combination Gas Control

Application

These intermittent pilot gas controls are used in gas-fired

appliances with capacities up to 300 feet

3

/hour at 1 inch

wc pressure drop [8.5 meters

3

/hour at 0.25 kPa] for natural

gas. They include a manual valve, two automatic operators,

a pressure regulator, pilot adjustment and a conduit cover.

The ambient temperature range for the standard-opening

TRADELINE

®

model (VR4304M) is -40

°

to +175

°

F

[-40

°

to +79

°

C].

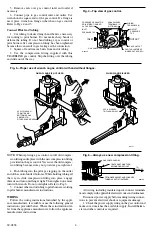

BODY PATTERN: Straight-through.

INLET X OUTLET SIZES AVAILABLE: 1/2 x 3/4 inch

and 3/4 x 3/4 inch.

This TRADELINE gas control comes with two 3/4 to

1/2 inch NPT bushings and one 1/2 to 3/8 inch NPT

bushing.

ADAPTERS: Adapters available for 1/2 and 3/4 inch

straight and angle connections. Refer to Table 2.

ELECTRICAL RATINGS:

Voltage and Frequency: 120 Vac, 60 Hz.

Current Draw: 0.14A.

TRADELINE

®

CAPACITY:

Use conversion factors in Table 1 to convert capacities

for other gases.

TABLE 1—GAS CAPACITY CONVERSION FACTORS.

Gas

Specific

Gravity

Multiply Listed

Capacity By

Manufactured

0.60

0.516

Mixed

0.70

0.765

Propane

1.53

1.62

TABLE 2—ADAPTER (FLANGE) PART NUMBERS.

Part Number

Inlet/

Outlet

Pipe Size

Flange

Type

Without

Hex

Wrench

With

Hex

Wrench

1/2 inch NPT

Straight

393690-6

393690-16

Elbow

393690-3

393690-13

3/4 inch NPT

Straight

393690-4

393690-14

Elbow

393690-5

393690-15

NOTE: Flange Kits include one flange with attached O-ring

and four mounting screws.

APPROVALS:

American Gas Association design certificate:

L2025007.

Canadian Gas Association design certificate:

L2025007.

Australian Gas Association design certificate:

Applied for.

Delta C.