U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

32-00015—05

10

TROUBLESHOOTING

Important Information

1.

When connected to an approved Burner control Sys-

tem, additional EMC tests are not required.

2.

All external connection should not exceed 30 VDC. If

higher voltage operation is required, approved inter-

posing relay should be used.

3.

The U2 must be powered using a isolated 24VDC

SELV (Safety Extra Low Voltage) power supply.

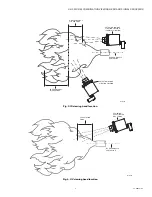

Maintenance

There are no user replaceable parts in U2.

Depending upon the application, periodic cleaning of the

lens may be necessary. Usually, the pressurized front of

the lens prevents dirt and debris from depositing on the

lens. Make sure positive pressure is maintained under all

firing conditions.

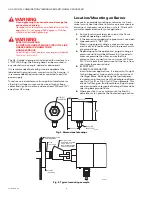

User Interface

Interface Techniques:

TAP: Press a finger on a button and remove.

SCROLL: Press a finger on the glass and move the finger

in circles (twirl).

RAMP: Hold a finger on the + or - button.

Two button interface (BACK and ENTER). Everything else

can be done by scrolling.

Interface Modes:

FLAME DISPLAY: Tap BACK (may require more than on

tap).

HELP: Tap + or - (from display).

LAST MENU: Tap ENTER, move through menu with taps or

scrolls.

ADJUST MODE: Tap ENTER from adjustable menu item,

change value using any technique.

NO YES MODE: Change to YES and tap STORE.

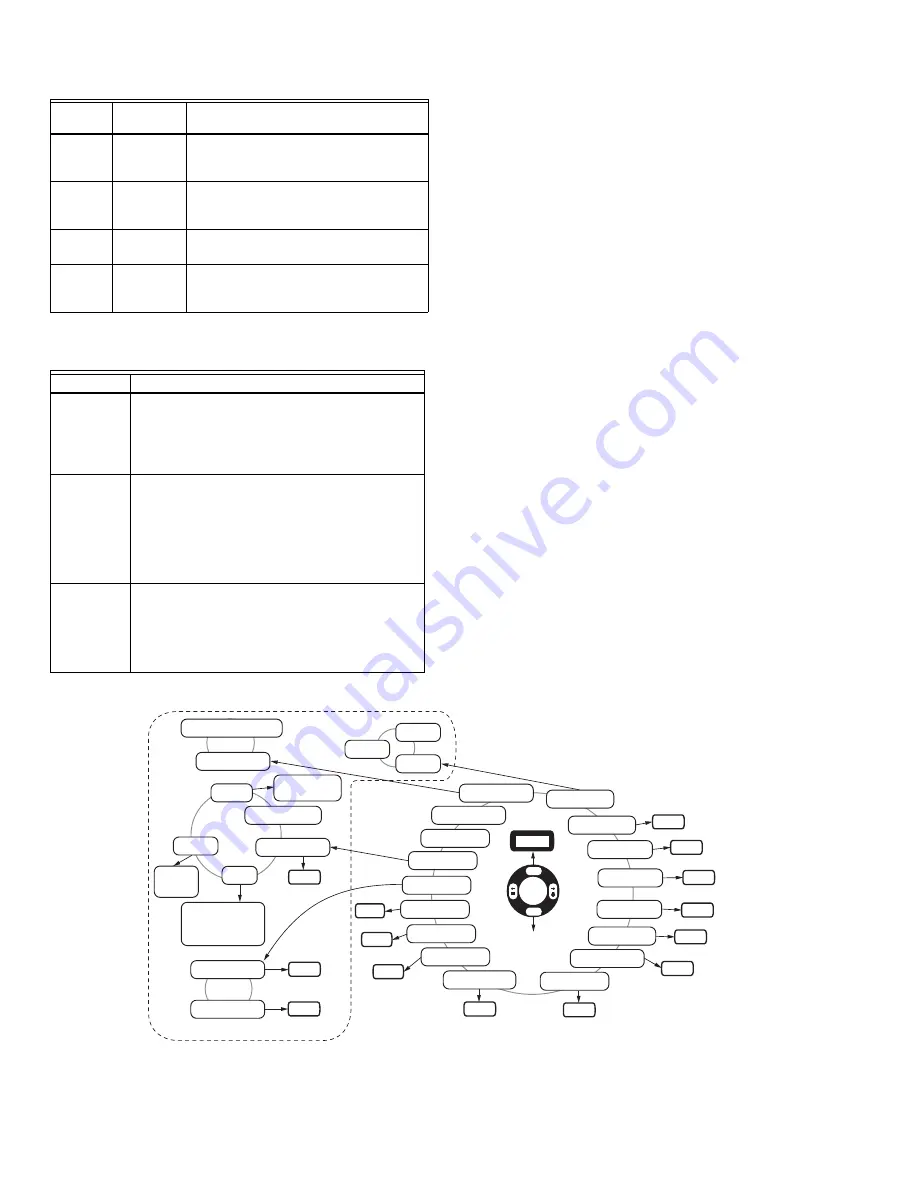

Fig. 6. User interface menu overview.

NOTE:

If a sensor is not available in your model, then no menu item will exist for sensor setting. See Table 1, “Models

and Associated Features.,” on page 2 to determine which sensors are active in your U2 model.

6

UVTUBE

SENSOR

SUPPLY

UVtube sensor supply failure. Device must be

replaced.

8

IR SENSOR

IR Sensor failure. Adjust gain or apply orifice to

lower flamecount. If failure persists, replace

device.

14

RELAY DRIVE

FAILURE

Relay drive failure, device must be replaced.

16

POWER

FAILURE

Clear Lockout. Verify power source is correctly

set before continuing (24V @120ma). If error

persists device must be replaced.

Symptoms

Remedies

No Display

1.

Check 24 VDC power connections and level at red

and black wires.

2.

Turn off power completely for 10-20 seconds to

allow for internal thermal fuse to reset.

3.

Check ambient temperature is below 70C (158F)

Display ON but

flame relay

contact not

closing when

flame

recognized

Check wiring as follows:

1.

Continuity between common (green) wire and yel-

low (this should be closed when power is applied -

Self Check Relay)

2.

If 1 above shows continuity, repeat test with green

and grey wire (Flame relay). Make sure flame LED

shows Flame relay is energized.

Lack of

communicatio

n on Modbus

A unique address must be used for each loop. Address "0"

disables communication. Check communication settings in

menu.

If using a converter, make sure the dip switches are set

correctly. For further troubleshooting, check vendor

information for the converter used.

Lockout

Code

Failure

Cause

Action

M35420

GT32

GU32

FU09

GI32

FI04

GM32

0800

0600

RT01

TD03

*F01

A000

FILE DEFAULT

0000

0000

PANEL LOCK

TIME OUT MIN

FACTORY DEFAULT

RS485

PARITY

HOURS

4 SUB MENUS

LAST MENU

HELP

HELP

°F OR °C

VERSION

ADDRESS-

DEFAULT

127 °F

GAIN TUBE UV-

GAIN SS UV-

FILTER SS UV-

GAIN IR-

FILTER IR-

GAIN MA OUT-

FLAME ON-

FLAME OFF-

FFRT-

TIME DELAY-

FILE

PANEL

COMMS

AUTO GAIN

AUTO FILTER

0->20 OR 4->20

READ ONLY

WRITE ONLY

NONE

ODD

EVEN

2400

9600

38400

115200

4800

19200

57600

BAUD

3425

ENTER

STORE

BACK