2

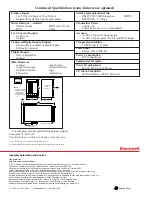

UDC 6300 – Compact, Powerful and Easy to Use

Standard panel mounting – shorter case depth

(72 x144 DIN bezel)

Dual displays show process values, multilingual prompts,

PV tag and ID tag

Display loop one, loop two, or both

Bargraphs display setpoint, process variable and

output values

Three local setpoints, plus remote; or computer setpoint

Display flashes during alarm condition

Manual/automatic control mode indicator

Alarm indicators

Sealed tactile feedback keyboard; security code

prevents tampering

Alarm acknowledge key

Industry-Specific Experience

At Honeywell, we focus on key industries for which

we supply effective, time-proven industrial automation

solutions. These industries include:

• Hydrocarbon Processing

• Oil and Gas

• Chemicals and Pharmaceuticals

• Pulp and Paper

• Food and Consumer Goods

• Power Generation

• Manufactured Goods

Honeywell’s commitment to these industries is illus-

trated the world over. For example, our products help:

• refineries produce more than half the world’s supply

of gasoline

• paper mills turn out 40-million metric tons of pulp and

paper each year

• fifteen of the world’s largest chemicals companies

achieve manufacturing competitiveness.

Our market-specific approach gives you the benefit of

practical knowledge of your industry, challenges, and process.

The UDC 6300 is Honeywell’s easy-to-use, yet

powerful process controller. From stand-alone control

to a solution fully digitally integrated with Honeywell’s

SCAN 3000 or TDC 3000

X

distributed control systems,

the UDC 6300 is suited for a variety of applications.

The UDC 6300 provides all the power you need in

a process controller, yet it’s easy to configure, install

and operate. Designed to handle continuous process

applications, the 6300 provides all the benefits you

expect from a Honeywell LeaderLine controller:

• fast installation and start-up

• application flexibility

• improved process quality and efficiency

• operator confidence

• Honeywell quality and global support.

You get all the power you need: multilingual prompts,

flexible math options, preconfigured algorithms, logic,

and ACCUTUNE™ adaptive tuning. These features and

more make UDC 6300 the easiest-to-use process

controller you’ll find anywhere.

Clear Operator Interface

for Efficient Operation

UDC 6300 features bright displays, and a sealed,

splashproof keyboard for a rugged and informative

operator interface: