Soak

A

soak is a stage of firing where the temperature

is held steady for a certain length of time. There are two

adjustments for each soak: time and temperature.

SPRAMP: Set Point with Ramp

SPRAMP firing, one

of three ways to fire with the controller, is a single-ra�p

firing program. You can select the temperature you will

fire to and the length of time you want the furnace to

take to reach that temperature. (See set point.)

SPPROG: Set Point with Programming

SPPROG

firing is one of three types of firings you can do with this

controller. With the SPPROG firing program, you can

enter up to 12 stages of firing into the controller (six

ramps and six soaks). It uses the 12-segment program.

(See set point.)

USING THE KEYS

Plug your controller in. During normal temperature

display, which is what you see

after you first plug in, the top

part of the display window

shows the furnace temperature

in large numbers. The bottom

part of the display window is

blank. Press the

DISP

(display)

key. Each time you press this

1

83'

key, the display window shows a different message.

The messages displayed on the bottom half of the

display window are of two types: operation and set-�p.

Operation messages tell you what your furnace or kiln

is doing while firing or while in normal temperature

display. Set-up messages guide you through all the

set-ups.

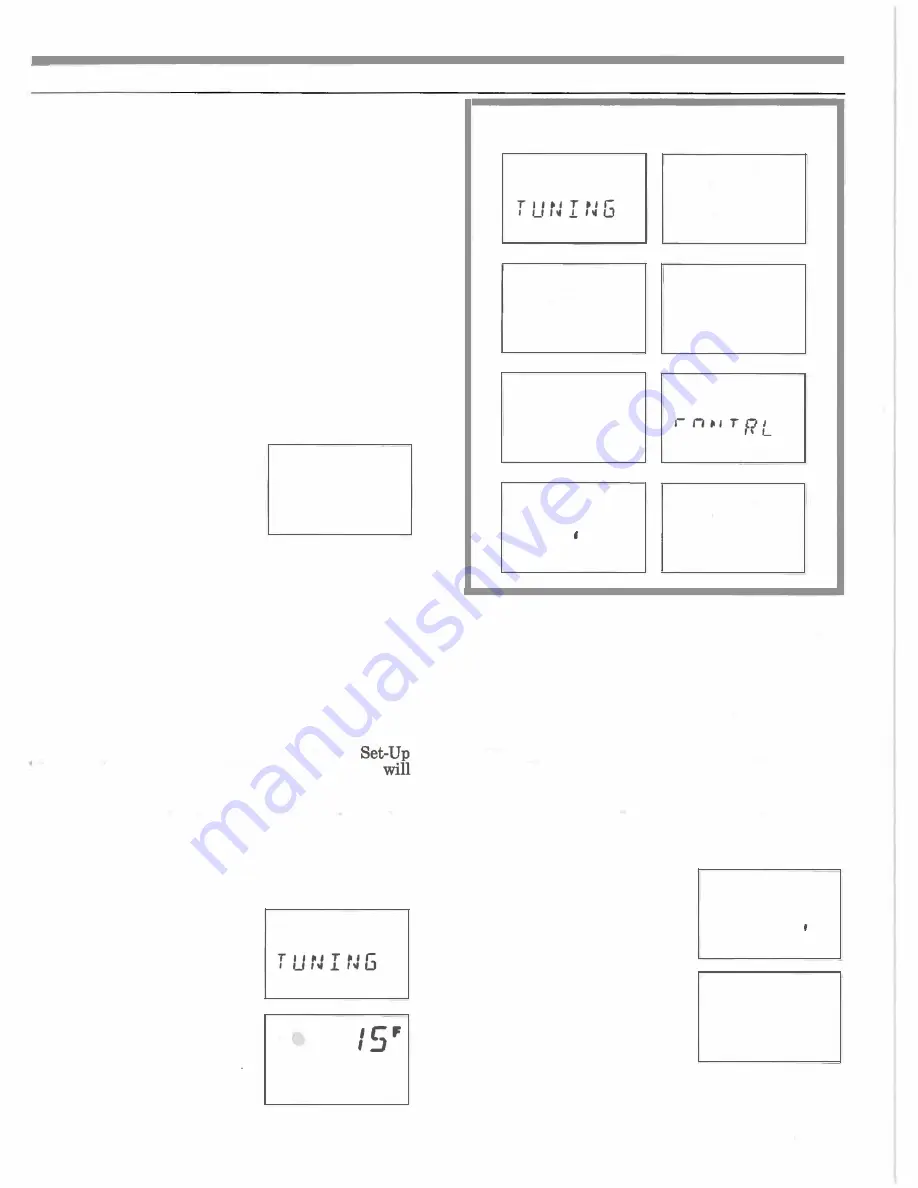

The set-up adjustments that you can make on the

controller are organized under a series of Set-Up Modes.

Press the

SET

UP

key. While the

SET

UP

key is held

down, the display window reading will take you throu�h

the eight Set-Up Modes one after the other. (See box thIS

page.) Or you can press

SET

UP

once for each

Mode. Each time you press the

SET

UP

key, you

see a different Set-Up Mode. The furnace temperature

disappears when the Set-Up Modes are displayed.

If you do not touch a key after a minute, the display

goes back to normal temperature display.

Press the

SET

UP

key again to get one of the eight

Set-Up Modes in the bottom of the display. Then press

the top left

FUNC

(function) key. Each time you press

the

FUNC

key, you will see a

different message. These mes

sages are the Function Mes

sages for the Set-Up Mode you

are in. For instance, "CYC TI" is

a Function Message under the

"TUNING" Set-Up Mode.

The

FUNC

key works only

when a Set-Up Mode is dis

played. So i f you get

"KEYERR" when you press

the

FUNC

key, you are not in

a Set-Up Mode.

SET

ryr

L

L

r r

I 1.

F

USING THE KEYS

Set Up Modes

Sf T

SET

R T 11.1 E

I

W'II

SE T

T.'

p

lfT "

.L

III

U

I

I

[RL

T.,

P"

T ",

.L 'II

W I

,

,

,

,

SE T

�

P

R R

r1 P

SET

RLGOR

Sf T

,_ U'" I

,

,

,

I?E R 11'

t TRTllt

ool

I

' Wool

If you press the

DISP

key while a Set-Up Mode is

displayed, the controller display goes back to normal

temperature display.

The Function Messages are lists of adjustments that

you can make under each Set-Up Mode. After you use

the

FUNC

key to display a Function Message, you

can

use the up and down arrow keys to make adjustments.

Arrow keys will raise or lower time and temperature

settings and tum features on and off. If you make

�

adjustment and then decide you want to go back to

�

e

setting you had before, you can do that by pressmg

RESET.

The

RESET

key will work only if the Function

Message is still displayed and you have not y�t

pre$sed the

DISP

key.

Exercise

1:

Press the

SET

UP

key until

INPUT

1

appears

in the bottom of the display win

dow. Then press the

FUNC

key

until

UNITS

appears in the dis

play. Use an arrow key to

change the

F

to a

C

(or vice

SE T

F

versa). Now press the

DISP

key

to take you back to the normal

temperature display.

You have just changed the

temperature reading from OF. to

·C. (or vice versa). You entered

the

INPUT

1 Set- Up Mode, and

T.,

PU

T "

.L

'II

"

1F

"�'TTC

,_,

,

\' 1.

I

.l

F

changed the

UNITS

Function Message with an arrow

key. Now change the

UNITS

Function Message back to

the way you had it if you want.

4