Output Calibration

300

UDC3500 Universal Digital Controller Product Manual

3/07

6.4 Third Current Output Calibration

Introduction

Calibrate the controller so that the output provides the proper amount of current over the

desired range. The controller can provide a current output range of from 0 mA to 21 mA.

The controller is usually calibrated at 4 mA for 0 % of output and 20 mA for 100 % of

output, but it may be calibrated for any other values between 0 mA and 21 mA. It is not

necessary to re-calibrate the controller in order to change from 4 to 20 mA operation over

to 0 to 20 mA operation; a simple configuration change is all that is required. See the CO

RANGE configuration for Third Current Output in

Sub-section 3.22

for details.

Equipment Needed

You will need a calibrating device with whatever accuracy is required, capable of

measuring 0 to 20 mA.

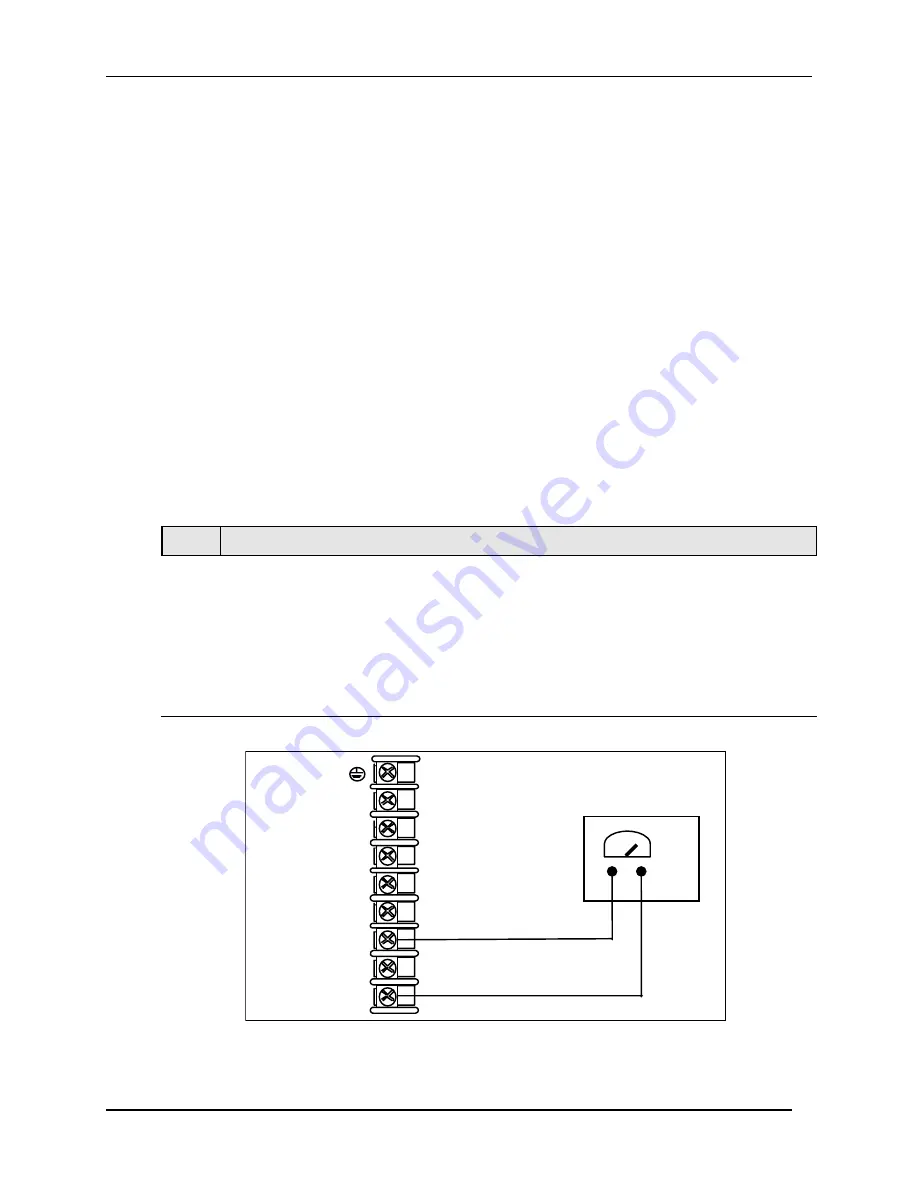

Calibrator Connections

Refer to Figure 6-3 and wire the controller according to the procedure given in Table 6-5.

Table 6-5 Set Up Wiring Procedure for the Third Current Output

Step

Action

1

Apply power and allow the controller to warm up 30 minutes before you calibrate.

2

Set LOCK in the Tuning Set Up group to NONE.

3

Tag and disconnect the field wiring, at the rear of the controller, from terminals 7 (+)

and 9 (–). See Figure 6-3.

4

Connect a milliammeter across these terminals.

Milliammeter

+

_

+

_

L2/N

L1

4

5

6

7

8

9

Curre nt

Output 3

Figure 6-3 Wiring Connections for Calibrating Third Current Output

Summary of Contents for UDC3500

Page 16: ......

Page 459: ...3 07 UDC3500 Universal Digital Controller Product Manual 443 ...