UV100E ULTRAVIOLET SYSTEMS

68-0262—5

4

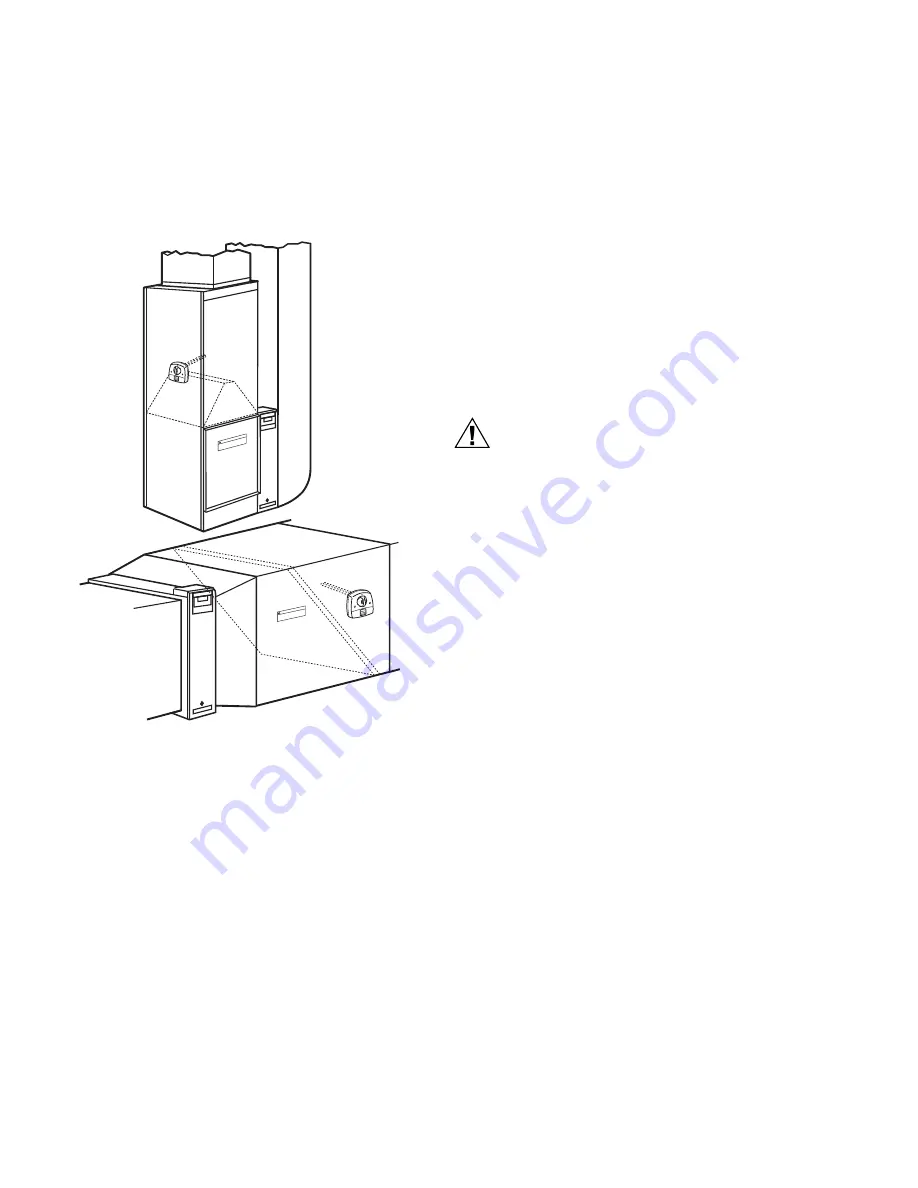

Surface Treatment System

When installed next to the cooling coil, the Surface Treatment

System prevents a high percentage of the growth of

micro-organisms such as mold that may grow on duct

surfaces, coils and drain pans. Individual results depend on

careful installation and maintenance. See. Fig. 2.

Fig. 2. Typical Surface Treatment installations.

IMPORTANT

If mounting options are limited, protect plastic or

rubber materials listed in CAUTION with ultraviolet-

resistant material such as aluminum foil duct tape.

NOTE: When the installer is uncertain about whether the drip

pan in the installation can tolerate UV exposure,

consult the UV exposure white paper, form no.

50-8788, at hbctechlit.honeywell.com Web site.

1.

Choose a location that is readily accessible for regular

inspection and cleaning. Fig. 1 and 2 and show possible

mounting locations.

2.

Allow clearance in front of the device for removing the

lamp assemblies. Fig. 3 shows lamp assembly lengths.

3.

Be sure depth can accommodate full length of UV lamp

for your model as shown in Fig. 3.

4.

Be sure duct mounting location is 8 in. wide minimum.

5.

Be sure 120 Vac electrical outlet is within range of unit to

plug in the power cord.

6.

Select single-lamp and dual-lamp air treatment system

location on HVAC return air duct that is easily accessible

with a flat mounting surface. Select surface treatment

system location on HVAC supply air duct that is easily

accessible with a flat mounting surface; locate the unit so

the lamp can surround the evaporator coil and drip pan

with ultraviolet light.

7.

Mount to allow correct operation:

a. Do not mount upside down.

b. Do not mount with lamps facing up.

CAUTION

Sharp Edges Hazard.

Can cause personal injury.

Be careful when inserting ultraviolet device into sheet

metal cutout.

Wear protective gloves when working near sheet metal.

Duct Mounting

Use the following instructions to mount the UV System on the

air duct of an HVAC system:

1.

Disconnect power to the HVAC system before installing

the UV System.

2.

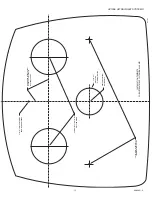

Select the appropriate template for your model (see Fig.

18-20).

3.

Place the appropriate template for your model on the

duct surface, centering the bulb hole(s) on the duct.

4.

Mark the location on the duct for 2 in. diameter bulb

hole(s), unit mounting-screw pilot holes, and when

installing a return air model, the 1-1/2 in. airflow sensor

hole.

5.

Cut 2 in. bulb hole(s) and 1-1/2 in. airflow sensor hole in

the duct. Remove any burrs.

Note that the airflow sensor

protrudes out of backside of device. Be careful to avoid

scratching or damaging the airflow sensor.

6.

Use a 3/32 in. drill for pilot holes for mounting screws.

7.

Be sure duct surface is flat after all holes are drilled.

8.

Position entire base unit on duct.

Be sure bulb and

airflow sensor holes in duct align with unit holes. Be

careful to avoid scratching or damaging the airflow

sensor.

9.

Install unit into duct using three (or two, depending on

model) no.10, 2 in. Phillips head sheet metal mounting

screws provided. (A spare screw is provided for three-

screw model.)

10.

Tighten screws to 12 to 14 in.-lb so space between case

and duct is sealed.

M22859

WARNIN

G/AVER

TISSEM

ENT

!

Nocifs pour

la peau

nue et l

es

Veuille

z lire e

t bien

comp

rendre

l’insta

llation

et la m

ainten

ance.

WARNING/

AVERTI

SSEM

ENT

!

Nocifs p

our la

peau

nue et

les

Veuille

z lire et bie

n compr

endre

l’instal

lation et

la ma

intenanc

e.