UV100E ULTRAVIOLET SYSTEMS

7

68-0262—5

16.

For air treatment systems, wait ten minutes for the

airflow sensor to calibrate. During this time, the furnace

fan must remain off.

NOTE: Failure to wait ten minutes for the airflow sensor to

calibrate before powering the furnace causes the

airflow sensor to incorrectly calibrate and the device

to incorrectly function. If this occurs, remove power to

the furnace or turn off the system and fan, wait ten

minutes, and then resume normal furnace operation.

17.

Reconnect the power to the HVAC system.

18.

Choose a location on the adjacent HVAC equipment for

the HVAC maintenance UV warning label included in the

UV system packing box. Choose a location that a future

installer can easily see during any future HVAC

maintenance or repair.

19.

Adhere the HVAC maintenance UV warning label to the

HVAC equipment (selected in step 17) such as the

furnace, air cleaner or humidifier. See Fig. 8.

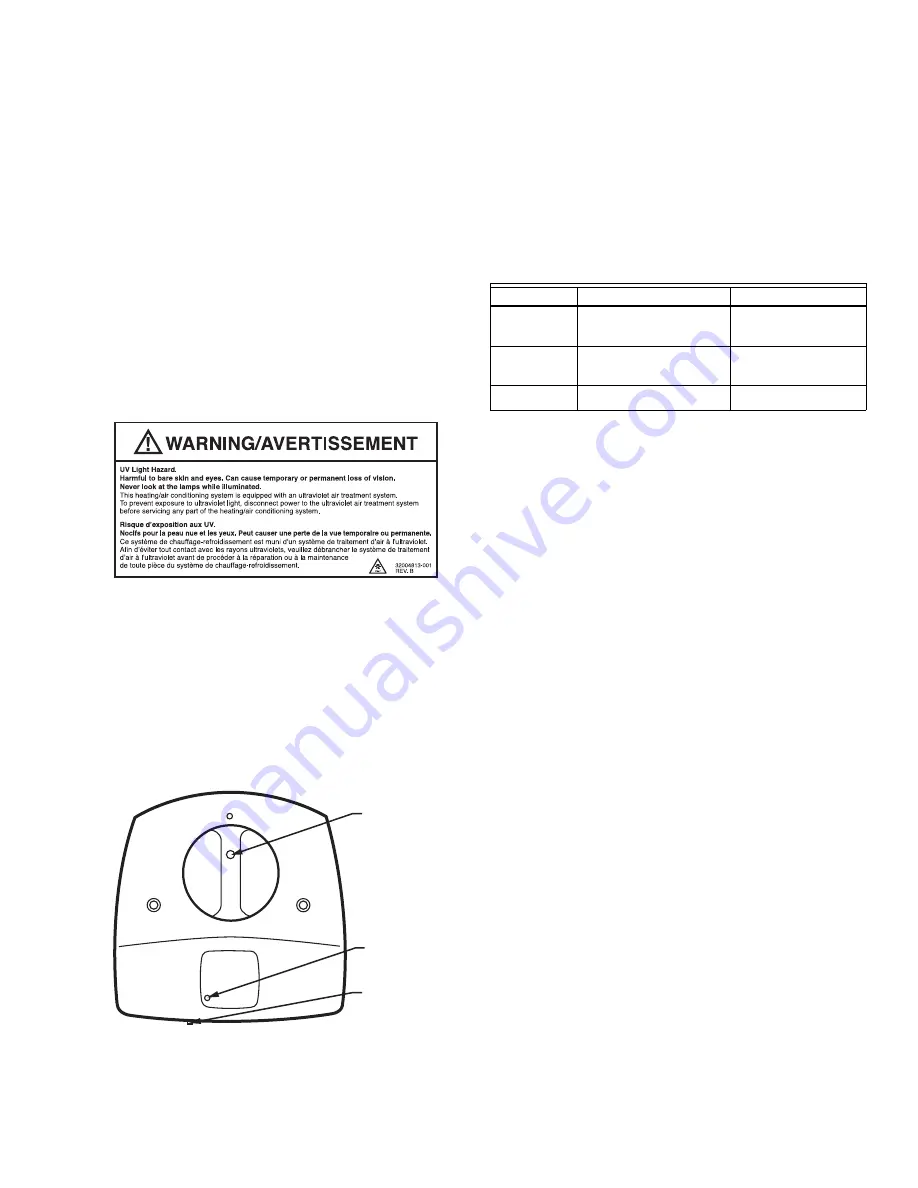

Fig. 8. HVAC maintenance UV safety label.

CHECKOUT

The installer should verify that the ultraviolet bulb(s) are

operating

only

by viewing the lamp light indicator

on the lamp

handle.

Do not attempt to look directly into the duct to see the

illuminated ultraviolet bulbs.

See Fig. 9.

Fig. 9. Lamp light indicator, LED and reset button.

The installer should orient the homeowner to the unit by

showing them the blue glow of the lamp light indicator and

discussing how to determine when the unit is functioning

properly without looking directly into the duct to see the

illuminated ultraviolet lamp. The installer should also

emphasize the hot surface and electrical shock safety

warnings.

The installer should show the homeowner the LED on the front

of the UV system and explain operation as follows:

a

Bulb life means emitting adequate amount of UV-C energy to

maintain an effective kill rate. At 0% bulb life remaining, the

lamp continues to operate until catastrophic bulb failure (bulb

burns out) but the kill rate becomes rapidly negligible.

Installer should also orient the homeowner to the reset button

on the bottom of the UV system that, when pressed briefly for

one second, can be used to command lamp on for the

minimum run time of 40 minutes (air treatment system) or three

hours (surface treatment system), depending on system type.

And that when a new bulb is installed, the homeowner must

hold the reset button for five seconds to reset the internal

timers. Cycling power does not reset internal timers.

When using Enviracom communication bus to communicate

with other appliances, the installer should orient the home-

owner to the Enviracom LED and three screw terminals. The

Enviracom LED flashes when transmitting and lights solidly

when there is a fault.

The installer should also explain the extended-bulb life for the

surface treatment system. For the single-lamp and dual-lamp

air treatment systems, the installer should orient the home-

owner to the alternate method of using the UV system to

monitor the thermostat load information to turn lamp off and on

instead of using the air flow sensor to control lamp operation

and that it communicates the percent remaining bulb life.

The installer should leave the Owner’s Guide with the

homeowner and review the bulb cleaning and replacement

procedures. A Bulb Cleaning Reminder Schedule is included in

the Owner’s Guide to help the homeowner set up and track a

regular cleaning schedule.

M22868

M22855

LAMP LIGHT

INDICATOR

LED CHANGE

INDICATOR

RESET

BUTTON

LED Status

Indicates

Homeowner Action

Off

100 to 11% bulb life

a

remaining

Nothing

Flashing

10 to 1% bulb life

a

remaining

Purchases bulb(s)

Solid

0% bulb life

a

remaining Replaces bulb(s)