V8200 COMBINATION GAS CONTROLS

68-0045—3

4

INSTALLATION

When Installing this Product…

1.

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to ensure the product is suitable for your

application.

3.

Ensure installer is a trained, experienced service

technician.

4.

After installation is complete, use these instructions to

check out product operation.

WARNING

Fire or Explosion Hazard.

Can cause serious injury, death or property

damage.

Follow these warnings exactly.

1. Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas, turn

off gas supply at the appliance service valve before

starting installation, and perform Gas Leak Test

after completion of installation.

3. Do not bend pilot tubing at gas control or pilot

burner after compression fitting has been tightened.

Gas leakage at the connection may result.

4. Always install sediment trap in gas supply line to

prevent contamination of gas control.

5. Do not force the gas control knob. Use only your

hand to turn the gas control knob. Never use any

tools. If the gas control knob will not operate by

hand, the gas control should be replaced by a

qualified service technician. Force or attempted

repair may result in fire or explosion.

CAUTION

Equipment Damage Hazard.

Improper wiring can damage equipment.

Never apply a jumper across or short the valve coil

terminals. This may burn out the heat anticipator in the

thermostat.

IMPORTANT:

These gas controls are shipped with protective seals

over inlet and outlet tappings. Do not remove seals

until ready to connect piping.

Follow the appliance manufacturer’s instructions if available;

otherwise, use the instructions provided below.

Convert Between Natural and LP Gas

WARNING

Fire or Explosion Hazard.

Can cause serious injury, death or property

damage.

1. Do not use a gas control set for natural gas on an

LP gas system or a gas control set for LP gas on

natural gas system.

2. When making conversion, main pilot burner orifices

MUST be changed to meet appliance

manufacture’s specifications.

Standard- or slow-opening gas controls are converted from

one gas to another with a conversion kit. To convert from

natural gas to LP, use the 393691 LP Conversion Kit that is

included with the V8200 gas control. To convert from LP to

natural gas, use the 394588 Natural Gas Conversion Kit

(order separately). Step-opening gas controls can not be

converted.

To convert control from one gas to another:

1.

Turn off main gas supply to the appliance.

2.

Remove the regulator cap screw and pressure regulator

adjusting screw. See Fig. 2.

3.

Remove the existing spring.

4.

Insert the replacement spring with tapered end down.

See Fig. 3.

5.

Install the new plastic pressure regulator adjustment

screw so that the top of the screw is flush (level) with

the top of the regulator. Turn the pressure regulator

adjustment screw clockwise

eleven complete

turns. This provides a preliminary pressure setting

of about 10.0 in. wc (2.5 kPa) for LP regulator and

3.5 in. wc (0.9 kPa) for natural gas regulator.

6.

Check the regulator setting either with a manometer or

by clocking the gas meter. Refer to Startup and

Checkout.

7.

Install the new cap screw.

8.

Mount conversion label on control.

9.

Install control and appliance according to appliance

manufacturer’s instructions.

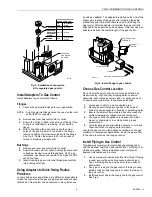

Fig. 2. Top view of gas control.

OUTLET

PRESSURE

TAP

INLET

OUTLET

WIRING

TERMINALS

INLET

PRESSURE TAP

PRESSURE REGULATOR

ADJUSTMENT

(UNDER CAP SCREW)

PILOT OUTLET

PILOT ADJUSTMENT

(UNDER CAP SCREW)

GAS

CONTROL

KNOB

M3093C

RED

RESET

BUTTON

THERMOCOUPLE

CONNECTION