1

69-0329—4

V8205, VR8205 Direct Ignition

Combination Gas Controls

Installation Instructions for the Trained Service Technician.

G. S. • Rev. 12-93 • ©Honeywell Inc. 1993 • Form Number 69-0329—4

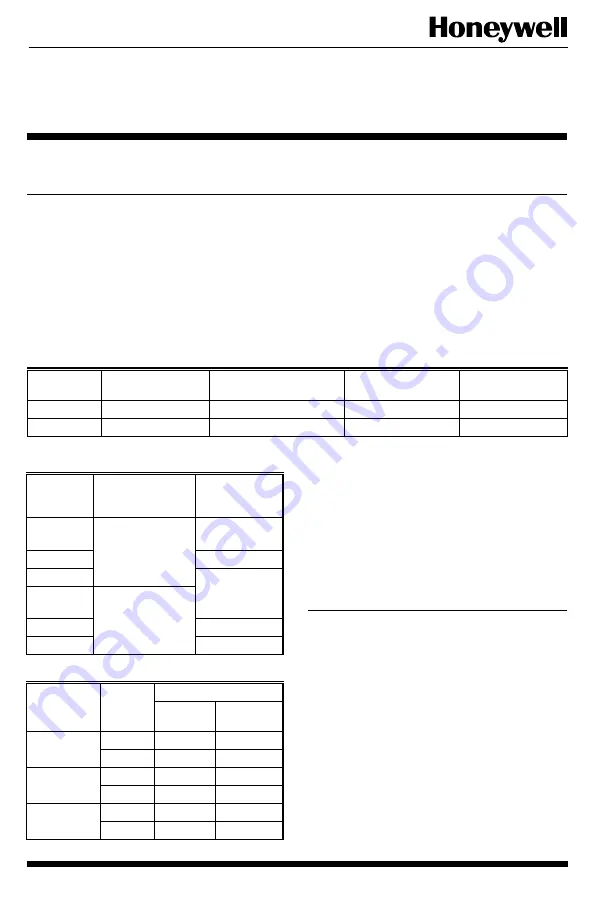

TABLE 1—DIRECT IGNITION COMBINATION GAS CONTROL MODELS.

TABLE 2—MODEL NUMBER

SUFFIX LETTER DESIGNATION.

TABLE 3—FLANGE PART NUMBERS.

NOTE: Flange Kits include one flange with attached O-ring

and four mounting screws. TRADELINE

®

kits include a

9/64 in. hex wrench, as noted.

APPROVALS:

American Gas Association design certificate: L2025006.

Canadian Gas Association design certificate: L2025006.

Australian Gas Association design certificate: 4214.

Approved for Delta C applications.

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condi-

tion.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your appli-

cation.

3. Installer must be a trained, experienced service tech-

nician.

4. After installation is complete, check out product op-

eration as provided in these instructions.

Part No.

Inlet/Outlet

Pipe Size

Flange

Type

Less Hex

Wrench

With Hex

Wrench

3/8 in. NPT

Straight

393690-1

393690-11

Elbow

393690-2

393690-12

1/2 in. NPT

Straight

393690-6

393690-16

Elbow

393690-3

393690-13

3/4 in. NPT

Straight

393690-4

393690-14

Elbow

393690-5

393690-15

Model No.

Suffix

Letter

Ambient

Temperature

Range

Regulator

Type

A

0° F to 175° F

Standard

[-18° C to 79° C]

C

Step-opening

H

Slow-opening

K

-40° F to 175° F

[-40° C to 79° C]

M

Standard

P

Step-opening

Model

Voltage/

Frequency

Number of

Automatic Operators

Gas Control

Knob Positions

Current Draw

V8205

24V/60 Hz

One

OFF-ON

0.30A

VR8205

24V/60 Hz

Two

OFF-ON

0.5A

These direct ignition gas controls are used in gas-fired

appliances with up to 200 cfh capacity on natural gas. They

include safety shutoff, a manual valve, one or two auto-

matic operators and a pilot adjustment. See Table 1 for

model differences and Table 2 for temperature ranges and

regulator types.

BODY PATTERN: Straight through with 1/2 in. inlet

and 1/2 in. outlet.

PIPE ADAPTERS: Angle and straight adapters available

for 3/8, 1/2 and 3/4 in. pipe. See Table 3.

These gas controls are factory-set for natural (and manu-

factured) gas or LP gas. Do not attempt to use a control set

for natural (manufactured) gas on LP gas, or a control set

for LP on natural (manufactured) gas.

Controls with standard or slow opening regulators can be

converted from one gas to the other with a conversion kit

(ordered separately). Order part no. 393691 to convert from

natural (manufactured) to LP gas; order part no. 394588 to

convert from LP to natural (manufactured) gas. Controls

with step opening regulators cannot be converted.

Application