7

69-0329—4

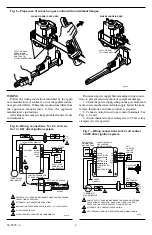

1. Turn off gas supply.

2. Set thermostat or controller above room temperature

to call for heat.

3. Watch for ignition spark or for glow at hot surface

igniter either immediately or following prepurge. See DI

module specifications.

4. Time length of igniter operation. See DI module

specifications.

5. After the module locks out, open manual gas cock

and make sure no gas is flowing to burner.

6. Set thermostat below room temperature and wait one

minute.

7. Operate system through one complete cycle to make

sure all controls operate properly.

SERVICE

WARNING

FIRE OR EXPLOSION HAZARD,

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH.

Do not disassemble the gas control; it contains no

replaceable components. Attempted disassembly

or repair may damage the control.

CAUTION

Do not apply a jumper across (or short) the valve

coil terminals, even temporarily. Doing so can

burn out the heat anticipator in the thermostat or

damage the DI module.

IF MAIN BURNER WILL NOT COME ON WITH

CALL FOR HEAT

1. Confirm that gas control knob is in the ON position.

2. Adjust thermostat several degrees above room tem-

perature.

3. Using ac voltmeter, measure voltage across mv ter-

minals at gas control.

4. If no voltage is present, check control circuit for

proper operation.

5. If proper control system voltage is present, replace

gas control.

INSTRUCTIONS TO THE HOMEOWNER

FOR YOUR SAFETY, READ BEFORE LIGHTING

WARNING

IF YOU DO NOT FOLLOW THE

WARNINGS BELOW AND THE

LIGHTING INSTRUCTIONS EXACTLY,

A FIRE OR EXPLOSION CAN RESULT

WITH PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

1. Before lighting, smell around the appliance

area for gas. If the appliance uses LP (bottled)

gas, be sure to smell next to the floor because

LP gas is heavier than air. If you smell gas,

immediately shut off the manual valve in the

gas piping to the appliance or, on LP, at the

tank. Do not try to light any appliance. Do not

touch any electrical switch or use the phone.

Leave the building and call your gas supplier.

If your gas supplier cannot be reached, call the

fire department.

2. Do not force the gas control knob on the appli-

ance. Use only your hand to turn the gas con-

trol knob. Never use any tools. If the knob will

not operate by hand, replace the control using a

qualified service technician. Force or attempted

repair may result in fire or explosion.

3. The gas control must be replaced if it has been

flooded with water. Call a qualified service

technician.

4. The gas control is a safety device. It must be re-

placed in case of any physical damage such as

bent terminals, missing or broken parts, stripped

threads, or evidence of exposure to heat.

IMPORTANT: Follow the operating instructions pro-

vided by the manufacturer of your heating appliance.

The information below will be of assistance in a

typical control application, but the specific controls

used and the procedures outlined by the manufac-

turer of your appliance may differ, and require spe-

cial instructions.

TO TURN ON FURNACE

STOP: Read the safety information above.

1. The lighting sequence on this appliance is automatic;

Do not attempt to manually light the main burner.

2. If the furnace does not come on when the thermostat

is set several degrees above room temperature, set the

thermostat to the bottom of its range to reset safety control.

!

!

!