VBN2, VBN3 CONTROL BALL VALVE/ACTUATOR ASSEMBLIES

62-0197—04

2

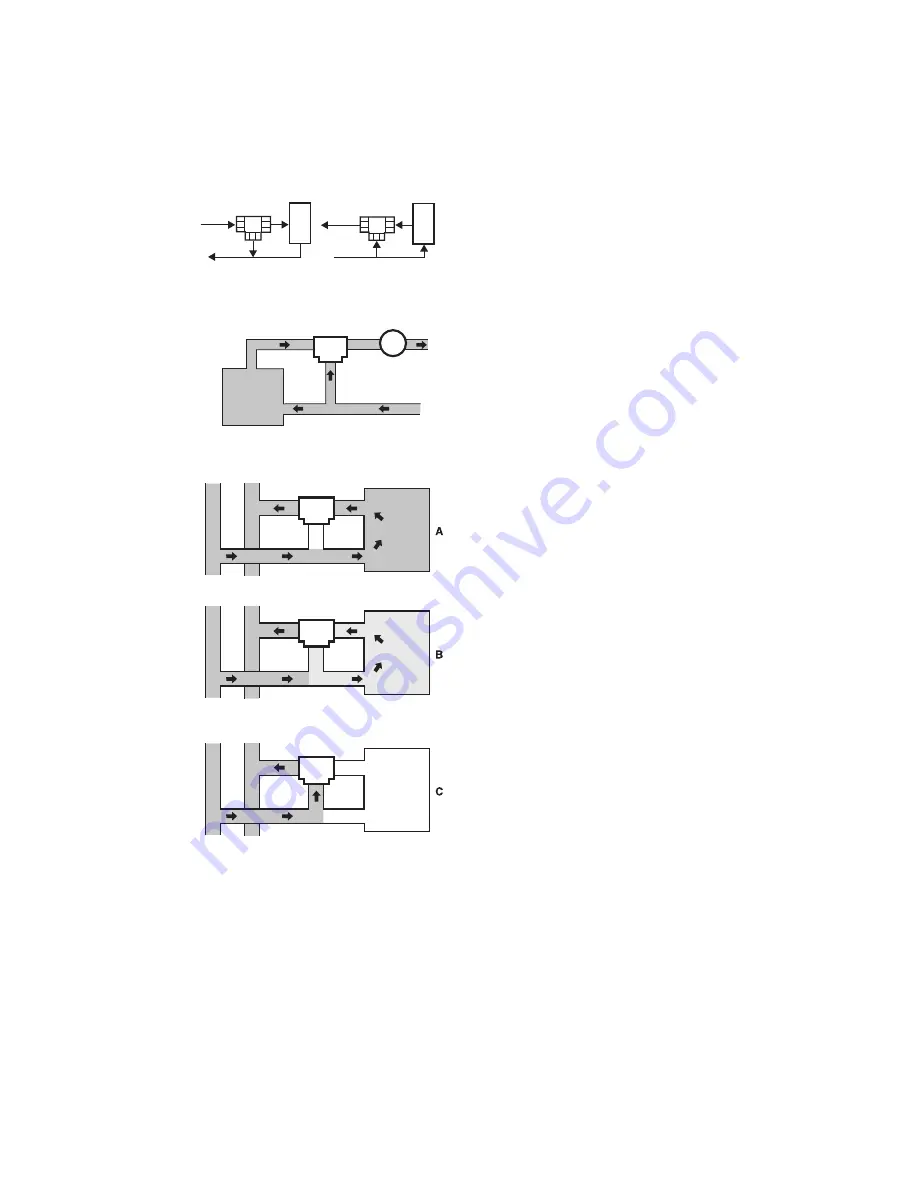

Fig. 3. Three-way ball valve flow orientation

(not to scale).

Fig. 4. Reset mixing control for discharge hot water.

Fig. 5. Three-way mixing valve operation

with coil bypass.

Mechanical Installation

The valveshave female NPT pipe fittings and should be

sealed with an approved pipe sealant or tape. Take care

not to use excess pipe dope to avoid interfering with

operation of ball. Torque should not exceed 75 ft-lb.

See Fig. 8 and 9 for valve dimensions. Refer to actuator

literature for actuator dimensions.

Mounting Plate Adjustment

The Actuator Mounting Plate can be rotated to a different

position for installation in confined spaces. This is

accomplished as follows:

1.

Remove the handle from the shaft and set it aside.

2.

Remove the two screws that hold the stem

assembly to the mounting plate and set them aside.

3.

Remove and set aside the stem assembly.

4.

Remove and set aside the two screws that attach

the mounting plate to the valve.

5.

ENSURE VALVE IS ISOLATED AND DEPRES-

SURIZED BEFORE PROCEEDING. Remove yel-

low pressure plate marked “HIGH PRESSURE”

from valve bonnet, rotate 90° or 180°, and re-install

screws using same holes in pressure plate and the

appropriate pair of tapped holes in the valve bonnet.

NOTE: Take note of the screw hole positions on

the valve. They limit the mounting plate

positions.

6.

Rotate mounting plate around valve top to the

desired position.

IMPORTANT

Do not rotate the valve stem while the hold-down

ring is removed. This can change the common

port from AB to A.

7.

Lower ring down to valve body and engage it in the

new position relative to the mounting plate.

8.

Tighten screws to valve body securing the mounting

plate.

9.

Reattach the stem assembly to the mounting plate.

10.

If desired, replace the handle on the shaft.

NOTE: See Fig. 6 for valve exploded view.

IMPORTANT

After adjusting a three-way valve mounting plate,

take note whether the AB port or the A port is the

common port.

Electrical Installation

1.

If necessary, remove actuator wiring cover.

2.

Wire the actuator according to the appropriate

diagram provided with actuator or job specifica-

tions. For detailed actuator information, see Honey-

well literature:

—

62-0274—MS7505/MS8105 Spring Return

Actuator Installation Instructions

—

63-2632—MN6105 Floating Actuator

Product Data

—

63-2633—MN7505 Modulating Actuator

Product Data

—

63-2209—ML6161/ML6164/ML7161/ML7164

Non-spring return direct Coupled Actuators

Product Data

3.

If applicable, position reverse/direct acting switch

for desired operation.

4.

Replace cover.

M13737

SUPPLY

RETURN

AB PORT

A PORT

B PORT

COIL

SUPPLY

RETURN

AB PORT

A PORT

B PORT

COIL

MIXING

DIVERTING

B

A AB

M29517

BOILER

PUMP

VBN3

AB

A

B

M19523

HEATING COIL

FULL

HEAT

5 GPM

5 GPM

2.5 GPM

5 GPM

AB

A

B

PROPORTIONED

HEAT

2.5 GPM

SUPPLY

MAIN

RETURN

MAIN

5 GPM

5 GPM

AB

VB3

VB3

VB3

A

B

NO

HEAT

NO FLOW

THROUGH COIL