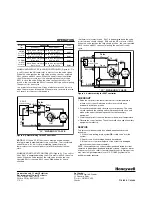

VC2, VC4, VC60, VC8

On-Off Actuator for VC Series Balanced Hydronic Valves

These 2-position (open/close) control

actuators

are used with VCZ

1000, 1100, 6000 and 6100 series hydronic valves in a normal

indoor environment to provide quick opening/closing to control the

flow of hot and/or chilled water or glycol solution to 60% concentra

tion. They are designed for on-off "zone" control of heating/cooling

systems, or to control individual fan coil, baseboard radiator or

convector applications.

Depending on the model selected, the actuator can be controlled

by a low or line voltage SPST or SPDT controller, such as a room

thermostat, aquastat or flow switch.

VC80 series valve actuators are designed to be used with hard

wired electronic thermostats with series anticipator or power

stealing thermostats. Recommended control thermostats include

T8601D, T8401C, T8380 and T8360 families.

VC actuators use cam-operated cartridge travel to resist water

hammer. Internal limit switches prevent motor overrun. Some of

these actuators have conformally coated printed circuit boards for

humidity resistance.

SPECIFICATIONS

The specifications following are nominal and conform to generally

accepted industry standards. Honeywell is not responsible for damages

resulting from misapplication or misuse of its products.

Voltage:

Label Colour Code

24V 50Hz ; 24V 60Hz Models

Blue

100-130 V 50-60 Hz Model

Black

200-240 V 50-60 Hz Model

Red

Power consumption:

6 Watts Max. at nominal Voltage (during valve position change).

Use 24 V Class 2 transformer.

Provide 6 VA per valve for transformer and connection wire sizing.

Maximum Duty Cycle:

15%

Nominal timing:

Valve opens in 6 seconds @ 60 Hz (20% longer @

50 Hz)

Electrical termination:

Available in 3 versions:

(1) Molex™ (header # 39-30-1060). Requires mating

connector (receptacle/housing # 39-01-2060). OR

(2) integral 1 meter [nominal 39"] leadwire cable.

(3) 5 feet [1.5 meter] plenum-rated cable per UL94-5V.

Includes plastic adapter for use with 3/8" flexible conduit.

End switch rating :

2.2 A inductive from 5 to 110 Vac,

1.0 A inductive above 110 to 277 Vac.

Min. DC switching capability: 5 mA @ 24 Vdc

Operating ambient temperature:

0 to 65

°

C [32 to 150

°

F]

Humidity Rating:

5-95% RH (non-condensing)

Fluid temperatures:

34 to 203

°

F [1 to 95

°

C]

Shipping & storage temperature:

-40 to +65

°

C [-40 to +150

°

F]

Atmosphere:

non-corrosive, non-explosive

Nominal Dimensions (Actuator only):

3-23/32" width x 2-11/16" depth x 2-3/4" height

94 mm width x 68 mm depth x 70 mm height

Accessories:

272866B Valve Flushing Cap

Form No.

95C-10920

© Honeywell Limited.

2003.02.24